Description

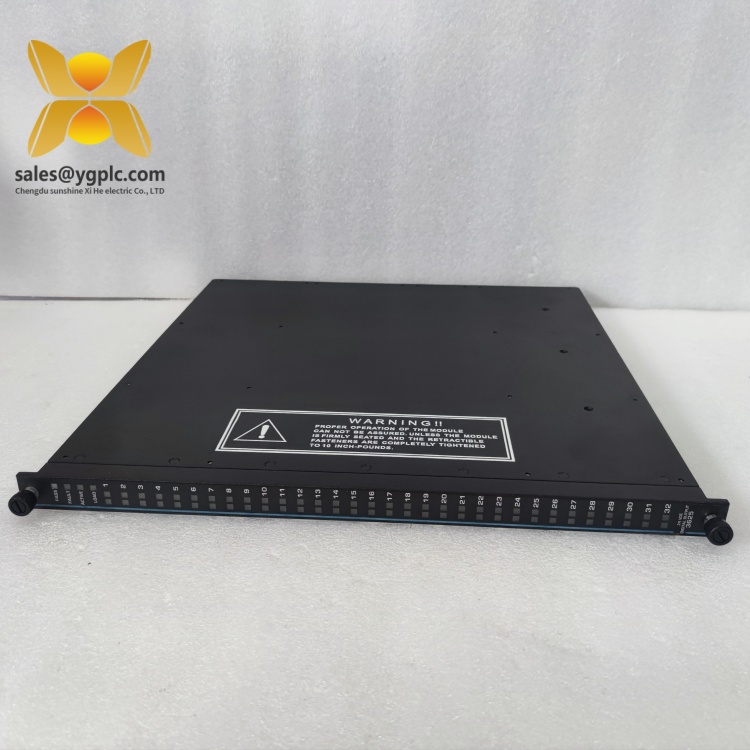

TRICONEX DO 3626X Digital Output Module

Product Overview

The TRICONEX DO 3626X is a high-performance digital output module designed for critical industrial automation and safety systems. Engineered with triple modular redundancy (TMR) architecture, this module ensures continuous operation even in the presence of single-point failures, making it ideal for applications requiring SIL 3-rated reliability . As part of the TRICONEX Trident series, the DO 3626X is specifically optimized for safety instrumented systems (SIS), emergency shutdown (ESD), and burner management systems (BMS) across industries such as oil and gas, power generation, and chemical processing .

Featuring 16 isolated output channels, the TRICONEX DO 3626X delivers precise control over external devices, including valves, actuators, and alarms. Each channel supports up to 0.5A of current, ensuring compatibility with a wide range of industrial loads . The module integrates seamlessly with TRICONEX’s TRICON CX platform, enabling real-time data exchange with distributed control systems (DCS) and other safety-critical components. Its compact design (120 mm x 80 mm x 60 mm) and lightweight construction (0.5 kg) facilitate easy installation in space-constrained environments, while compliance with CE, UL, and ATEX certifications guarantees operation in hazardous areas .

A key differentiator of the DO 3626X is its advanced diagnostics, which provide real-time insights into module health and performance. This includes self-testing capabilities that detect faults within milliseconds, minimizing downtime and maintenance costs. By leveraging the TRICONEX TMR technology, the module achieves an industry-leading fault self-diagnosis rate exceeding 99.9%, ensuring uncompromised system integrity . Whether used in standalone applications or integrated into complex industrial networks, the TRICONEX DO 3626X sets a benchmark for reliability, scalability, and ease of integration.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | TRICONEX |

| Product Type | Digital Output Module (Safety-Critical I/O) |

| Channels | 16 isolated channels |

| Output Current | 0.5A per channel |

| Voltage Range | 24 VDC (nominal), 16–32 VDC operating range |

| Communication Protocols | Modbus RTU/TCP, OPC (via TRICON Communication Module) |

| Physical Dimensions | 120 mm (W) x 80 mm (H) x 60 mm (D) |

| Weight | 0.5 kg |

| Working Temperature | -20°C to +60°C |

| Certifications | CE, UL, ATEX (hazardous environments) |

| Redundancy | Triple Modular Redundancy (TMR) |

DO 3626X

Related Products

- TRICONEX DO 3624: A 16-channel digital output module with optical isolation, suitable for non-hazardous environments.

- TRICONEX DO 3636R: A 32-channel relay output module with dry contact capability, ideal for high-power applications.

- TRICONEX 3625: A 16-channel digital output module with commoned supervision, designed for cost-sensitive projects.

- TRICONEX 3703E: An isolated analog input module that complements the DO 3626X in hybrid control systems.

- TRICONEX 4200 RMX: A fiber optic remote I/O module for extending the DO 3626X’s reach in distributed installations.

- TRICONEX 3664: A dual-channel digital output module with enhanced diagnostic features for critical processes.

Main Features and Advantages

Triple Modular Redundancy (TMR) Architecture: The DO 3626X employs three independent processing channels to eliminate single points of failure. In the event of a fault, the module automatically switches to a dual-channel configuration, ensuring continuous operation without downtime . This architecture is certified for SIL 3 applications, meeting the most stringent safety standards in industries like oil refining and nuclear power.

Advanced Diagnostics: Built-in self-testing mechanisms monitor each channel for faults, including open circuits, short circuits, and voltage irregularities. Faults are reported in real-time via status LEDs and integrated system diagnostics, enabling proactive maintenance and reducing mean time to repair (MTTR) .

Flexible Integration: The module supports industry-standard communication protocols (Modbus RTU/TCP) and interfaces seamlessly with TRICONEX’s TRICON CX platform. This allows integration with existing DCS systems, enabling unified control and monitoring across the plant floor .

Compact Design: Despite its robust functionality, the DO 3626X occupies minimal space, making it suitable for retrofitting into older systems or new installations with strict space constraints. Its lightweight design further simplifies handling and installation.

Hazardous Environment Compliance: With ATEX certification, the module is approved for use in explosive atmospheres, ensuring compliance with regional safety regulations in oil and gas production, chemical processing, and other high-risk sectors .

Installation and Maintenance

Pre-installation Preparations:

Before installing the TRICONEX DO 3626X, verify the system’s power supply compatibility (24 VDC nominal) and ensure proper grounding. Clean the mounting rail and inspect the module for physical damage. Use a torque screwdriver to secure the module to the DIN rail at 0.8–1.2 N·m, ensuring a stable connection. For redundant configurations, install two DO 3626X modules in adjacent slots and connect them via TRICONEX’s redundant communication cables .

Before installing the TRICONEX DO 3626X, verify the system’s power supply compatibility (24 VDC nominal) and ensure proper grounding. Clean the mounting rail and inspect the module for physical damage. Use a torque screwdriver to secure the module to the DIN rail at 0.8–1.2 N·m, ensuring a stable connection. For redundant configurations, install two DO 3626X modules in adjacent slots and connect them via TRICONEX’s redundant communication cables .

DO 3626X

Maintenance Suggestions:

- Routine Checks: Perform monthly visual inspections to check for loose connections, damaged cables, or overheating. Use TRICONEX’s TriStation software to review diagnostic logs and identify potential issues.

- Firmware Updates: Regularly update the module’s firmware to benefit from the latest security patches and performance optimizations.

- Spare Parts Management: Maintain a spare DO 3626X module to minimize downtime in case of failure. TRICONEX’s global supply chain ensures rapid delivery of discontinued or hard-to-find components .

- Environmental Monitoring: Ensure the operating temperature remains within -20°C to +60°C and humidity levels do not exceed 95% non-condensing.

Application Fields

The TRICONEX DO 3626X excels in a wide range of safety-critical applications:

- Emergency Shutdown (ESD) Systems: Triggers rapid shutdowns in oil refineries, offshore platforms, and chemical plants to prevent catastrophic failures.

- Burner Management Systems (BMS): Controls burner ignition, flame monitoring, and fuel supply in power plants and industrial boilers.

- High-Integrity Pressure Protection Systems (HIPPS): Monitors and manages pressure levels in pipelines and storage tanks to avoid overpressure events.

- Turbomachinery Control: Regulates steam turbines and gas generators in power plants, ensuring safe startup, operation, and shutdown.

- Process Automation: Manages valves, pumps, and alarms in pharmaceutical manufacturing and food processing facilities, where precision and safety are paramount.

In each scenario, the DO 3626X’s TMR architecture and advanced diagnostics mitigate risks, reduce operational costs, and ensure compliance with international safety standards.

DO 3626X

Product Guarantee

Our company, a leading industrial control parts distributor with 17 years of experience, offers a 1-year quality warranty for the TRICONEX DO 3626X, covering hardware malfunctions unrelated to misuse or improper installation. During the warranty period, we provide free replacement for modules exhibiting performance irregularities or functional failures. For urgent or discontinued models, our global supply chain network ensures rapid delivery of scarce spare parts, supported by 24/7 technical assistance. We stand behind the DO 3626X’s reliability and are committed to ensuring seamless integration and long-term system stability for our clients.

For inquiries, contact us via WhatsApp (+86 18859254943) or email (sales@ygplc.com).

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: