Description

Product Overview

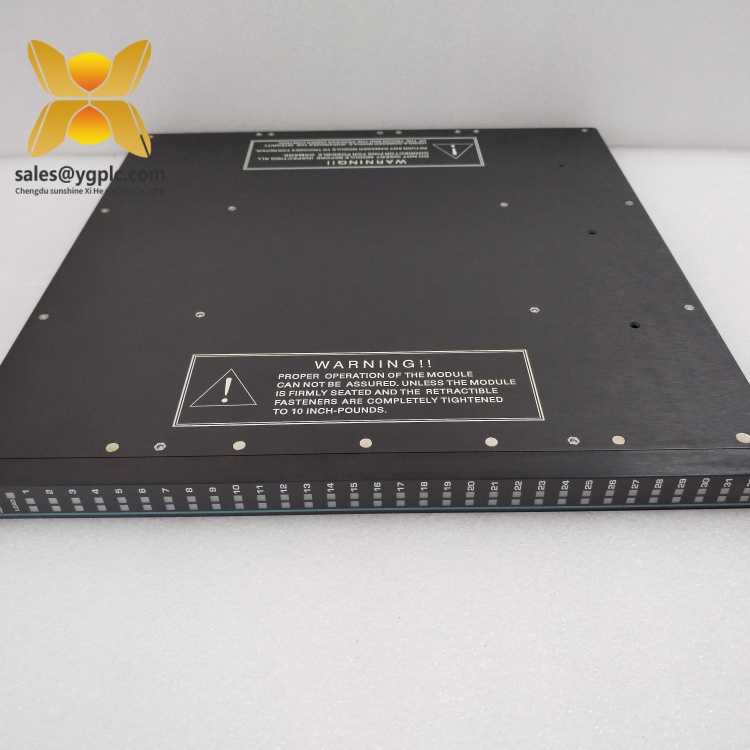

The TRICONEX 3625C1 is a critical communication module designed for integration within TRICONEX’s Tricon safety instrumented system (SIS), a platform renowned for its reliability in safety-critical industrial environments. As a key component in the Tricon series, the TRICONEX 3625C1 facilitates seamless data exchange between various system elements, ensuring that critical operational data is transmitted accurately and in real time. This module is engineered to meet the stringent demands of industrial automation, where downtime or communication failures can lead to significant safety risks or production losses.

The TRICONEX 3625C1 is specifically positioned to bridge the gap between different subsystems within a safety instrumented system, supporting interoperability with both legacy and modern industrial control components. Its design prioritizes stability and fault tolerance, making it an essential part of systems that require compliance with international safety standards, such as IEC 61508. By enabling consistent communication, the TRICONEX 3625C1 enhances the overall integrity of the automation system, ensuring that safety functions—such as emergency shutdowns or process interlocks—operate as intended when triggered.

Technical Specifications

| Product model | TRICONEX 3625C1 |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Communication module (for Tricon safety instrumented systems) |

| Operating voltage | 24V DC ±10% |

| Current consumption | 300mA max at 24V DC |

| Physical dimensions | 146mm (length) x 98mm (width) x 45mm (height) |

| Weight | 220 grams |

| Communication protocol | Supports Modbus RTU/ASCII, TCP/IP |

| Operating temperature range | -40°C to 70°C |

| Storage temperature range | -55°C to 85°C |

| Interface type | 2 x RS-485 ports, 1 x Ethernet port |

| Origin | United States |

3625C1

Related products

- TRICONEX 3626: A high-performance communication module in the same series as the TRICONEX 3625C1, offering expanded protocol support (including Profibus) for more complex industrial networks.

- TRICONEX 3700A: A power supply module designed to work with the TRICONEX 3625C1, providing stable 24V DC power to ensure consistent operation of communication components in the Tricon system.

- TRICONEX 4351B: An I/O module that pairs with the TRICONEX 3625C1 to collect field data (e.g., pressure, temperature) and transmit it via the communication module to the system controller.

- TRICONEX 7400151-001: A backplane connector essential for physically integrating the TRICONEX 3625C1 into the Tricon chassis, ensuring secure electrical connections.

- TRICONEX 9662-810: A diagnostic module that works alongside the TRICONEX 3625C1 to monitor communication health, flagging errors or latency issues for proactive maintenance.

- TRICONEX 2651: A legacy communication module that the TRICONEX 3625C1 replaces, offering improved speed and protocol compatibility while maintaining backward compatibility with older Tricon systems.

- TRICONEX 3805E: A redundant communication module designed for systems requiring high availability; it can be paired with the TRICONEX 3625C1 to create a fault-tolerant communication layer.

Main features and advantages

Reliable communication: The TRICONEX 3625C1 is built with redundant communication paths, minimizing the risk of data loss or transmission delays. This redundancy is critical in safety-critical environments, where even a brief communication failure could compromise system safety. Whether transmitting data between I/O modules and the main controller or relaying status updates to human-machine interfaces (HMIs), the TRICONEX 3625C1 ensures consistent performance.

Wide protocol support: The module’s compatibility with industry-standard protocols such as Modbus RTU/ASCII and TCP/IP makes the TRICONEX 3625C1 highly versatile. It can integrate with a wide range of third-party devices, including sensors, actuators, and other control systems, reducing the need for custom adapters or protocol converters. This flexibility simplifies system design and lowers integration costs.

Robust environmental tolerance: The TRICONEX 3625C1 is engineered to operate in harsh industrial conditions, with a wide operating temperature range (-40°C to 70°C) and resistance to vibration and electromagnetic interference (EMI). This durability ensures reliable performance in environments like refineries, chemical plants, and power stations, where dust, temperature fluctuations, and electrical noise are common.

Safety certification: Compliant with IEC 61508 up to SIL 3, the TRICONEX 3625C1 meets the highest safety standards for critical applications. This certification provides assurance that the module can be trusted in systems where failure could result in harm to personnel, environmental damage, or significant financial loss.

Easy integration: The TRICONEX 3625C1 is designed for seamless integration into existing Tricon systems, with plug-and-play functionality that reduces installation time. Its compact dimensions allow it to fit within standard Tricon chassis, and pre-configured software tools simplify setup, enabling technicians to quickly commission the module without extensive training.

3625C1

Installation and maintenance

Pre-installation preparations: Before installing the TRICONEX 3625C1, verify that the Tricon chassis is powered off and disconnected from the main power supply to prevent electrical hazards. Check the compatibility of the chassis with the module—ensure it is a Tricon system model that supports communication modules of the 3600 series. Inspect the module for physical damage, such as bent pins or cracks, which could affect performance. Prepare the necessary tools, including a screwdriver for securing the module to the chassis, and ensure the backplane connectors are clean and free of debris to maintain proper electrical contact. Confirm that the power supply (24V DC) meets the module’s requirements, as incorrect voltage can cause permanent damage to the TRICONEX 3625C1.

Maintenance suggestions: Regular maintenance of the TRICONEX 3625C1 is essential to ensure long-term reliability. Conduct visual inspections quarterly to check for loose connections, dust accumulation, or signs of overheating (e.g., discoloration). Use compressed air to gently clean dust from the module’s vents and connectors, taking care not to damage sensitive components. Monitor communication logs via the system’s diagnostic software to identify irregularities, such as increased latency or error rates, which may indicate a failing module. If faults are detected, power down the system before removing the TRICONEX 3625C1 to avoid data corruption or damage to other components. Store spare modules in a dry, temperature-controlled environment (-55°C to 85°C) to preserve their functionality for replacement purposes.

Application fields

The TRICONEX 3625C1 finds its primary application in safety-critical industrial sectors where reliable communication between system components is paramount. In the oil and gas industry, it is used in upstream production facilities, midstream pipelines, and downstream refineries. Here, the module enables real-time data transfer between emergency shutdown systems (ESDs), fire and gas detection systems, and process controllers. This ensures that if a hazardous condition (e.g., a gas leak or pressure spike) is detected, the TRICONEX 3625C1 facilitates the rapid transmission of signals to trigger shutdowns, preventing catastrophic incidents.

In chemical processing plants, the TRICONEX 3625C1 plays a key role in integrating batch control systems with safety interlocks. It ensures that process variables (such as temperature, pH, and flow rates) are continuously communicated to the SIS, allowing the system to intervene if parameters exceed safe limits. This is critical in facilities handling toxic or flammable chemicals, where even a small delay in communication could lead to chemical reactions or releases.

Power generation facilities, including fossil fuel, nuclear, and renewable energy plants, also rely on the TRICONEX 3625C1. In these environments, the module connects turbine control systems, boiler protection systems, and grid synchronization equipment to the SIS. It ensures that any anomalies—such as turbine overspeed or boiler tube failures—are immediately relayed, enabling the system to initiate protective actions (e.g., tripping the turbine) to prevent equipment damage or power outages.

Additionally, the TRICONEX 3625C1 is used in pharmaceutical manufacturing, where strict regulatory compliance (e.g., FDA guidelines) demands accurate and auditable data trails. The module’s reliable communication ensures that process data is consistently logged and shared with quality control systems, supporting compliance with production standards and traceability requirements.

3625C1

Product guarantee

Our company offers a one-year quality warranty service for the TRICONEX 3625C1, covering hardware malfunctions not caused by human factors. During the warranty period, if the TRICONEX 3625C1 shows abnormal performance or functional failure, we will provide replacement services to minimize downtime for your operations. As a leading import and export trade distribution company with 17 years of experience in the industrial control industry, we specialize in supplying industrial control spare parts, including many unpopular and discontinued models, with a large stock available.

Our supply chain advantages ensure that we can quickly respond to urgent demands for the TRICONEX 3625C1 or its alternatives, even if the model is scarce or discontinued. We provide comprehensive technical support, including assistance with installation guidance and troubleshooting, to ensure that the TRICONEX 3625C1 integrates seamlessly into your system. For inquiries or quotations, please contact us via Whatsapp:+86 18859254943 or E-mail :sales@ygplc.com. We are committed to supporting the continuous and stable operation of your industrial systems through reliable product supply and responsive service.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: