Description

Product Overview

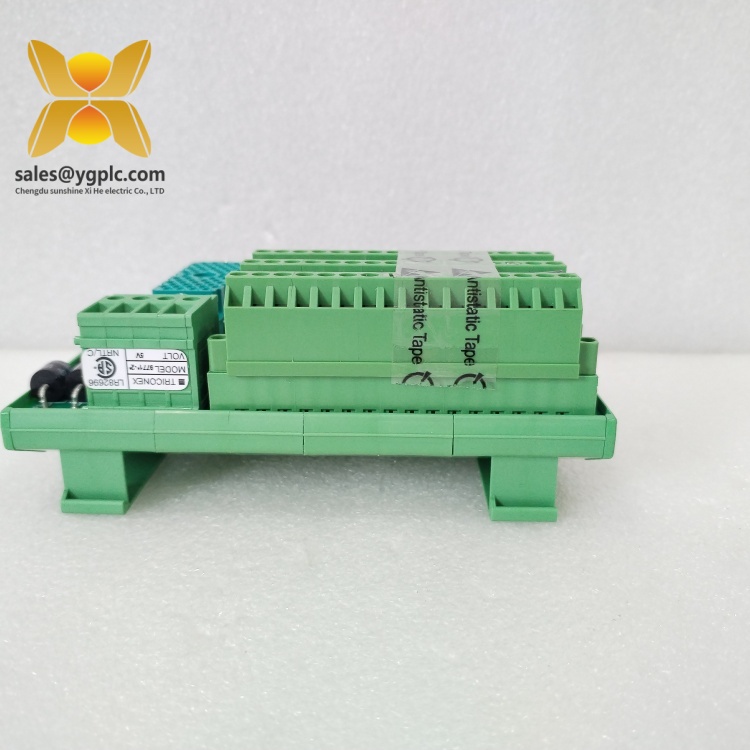

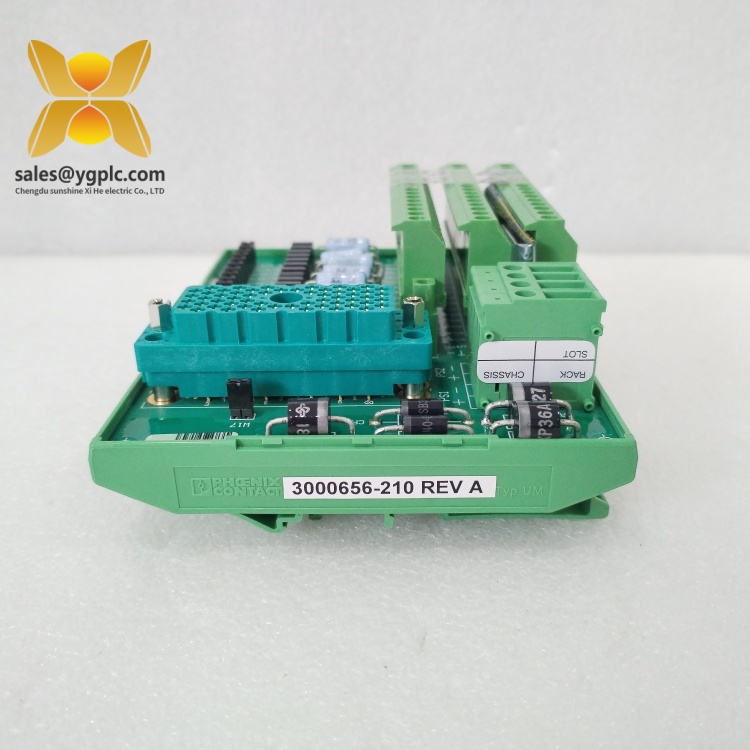

The TRICONEX 300656-210 is a communication interface module designed specifically for TRICONEX safety instrumented systems (SIS). Its core function is to enable data exchange between the TRICONEX controller and external devices or systems, acting as a bridge that ensures smooth information flow in industrial automation setups. This makes the TRICONEX 300656-210 a critical component in maintaining the integrity and responsiveness of safety-critical operations.

As part of TRICONEX’s family of system modules, the 300656-210 integrates seamlessly with TRICONEX Tricon and TriconEX platforms, which are widely used for their triple modular redundancy (TMR) architecture. This compatibility ensures that the module can support the high safety standards required in industries where any communication failure could lead to operational risks. The TRICONEX 300656-210 is valued for its ability to handle real-time data transmission reliably, making it an essential part of systems that need to monitor and respond to process conditions continuously.

Technical Specifications

| Product model | 300656-210 |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Communication Interface Module |

| Supported protocols | Modbus RTU, Ethernet/IP |

| Input voltage | 24V DC ±10% |

| Communication ports | 2 x Ethernet (RJ45), 1 x RS-485 |

| Physical dimensions | 145mm (W) x 175mm (H) x 215mm (D) |

| Weight | 1.3 kg |

| Working environment | Operating temperature: -40°C to +70°C; Relative humidity: 5% to 95% (non-condensing) |

| Place of origin | United States |

| Isolation | 2500Vrms between communication ports and system ground |

300656-210

Related products

- TRICONEX 4351B: The main processor module of TRICONEX Tricon systems. It relies on 300656-210 to send and receive data with external devices, ensuring the controller has up-to-date information for safety logic decisions.

- TRICONEX 9662-810: A parallel communication module that supports different protocols than 300656-210, serving as an alternative for systems requiring legacy interfaces like Profibus.

- TRICONEX 3625: A digital input module that sends field data to the controller. The controller uses 300656-210 to share this data with SCADA systems for monitoring.

- TRICONEX 8312: A redundant power supply module that provides stable 24V DC to 300656-210, ensuring uninterrupted communication even if the primary power source fails.

- TRICONEX 7400: A power distribution unit that supplies power to multiple modules, including 300656-210, in large-scale TRICONEX installations.

- TRICONEX 2401H: A digital output module whose status data is transmitted to external systems via 300656-210, allowing remote monitoring of field device operations.

Main features and advantages

Reliable data transmission: The 300656-210 is built with 2500Vrms electrical isolation between its communication ports and the system ground. This protects against electrical noise and surges common in industrial environments, such as factories or refineries, ensuring that data signals remain accurate and uninterrupted.

Multi-protocol support: The module works with widely used protocols like Modbus RTU and Ethernet/IP. This flexibility allows 300656-210 to connect TRICONEX SIS to various external systems, including SCADA, HMI, and third-party control systems, without the need for additional converters.

Seamless integration with TMR systems: Designed for TRICONEX’s triple modular redundancy (TMR) architecture, the 300656-210 can operate in redundant setups. This means if one module fails, a backup 300656-210 can take over immediately, preventing communication downtime—a critical feature for safety-critical applications.

Built-in diagnostics: The module has status indicators that show port activity, power supply health, and connection quality. This makes it easy for maintenance teams to quickly identify issues, such as a loose Ethernet cable or a failed protocol handshake, reducing troubleshooting time.

Compact design: With its small physical size, the 300656-210 fits easily into standard TRICONEX chassis, saving space in control cabinets. This is especially useful in retrofitting older systems where space is limited.

300656-210

Installation and maintenance

Pre-installation preparations: Before installing 300656-210, confirm it is compatible with the target TRICONEX chassis (e.g., TriconEX main racks). Check that the input voltage matches the 24V DC requirement. Ensure the mounting location has enough space for cable connections and ventilation to prevent overheating. Turn off the system power and disconnect all external communication cables to avoid electrical damage during installation. Inspect the module’s ports for damage, such as bent pins, before inserting it into the chassis.

Maintenance suggestions: For 300656-210, check the communication ports monthly for dust or corrosion—clean them gently with a dry cloth if needed. Use a network tester to verify that Ethernet/IP connections maintain stable speeds. Monitor the module’s status lights; a flashing red light indicates a communication error that needs immediate attention. In redundant setups, test the failover function quarterly to ensure the backup 300656-210 activates correctly if the primary module stops working. Keep the area around the module free of debris to maintain proper airflow and prevent overheating.

Application fields

The TRICONEX 300656-210 is widely used in industries where safety instrumented systems (SIS) require reliable communication with external systems. In oil and gas facilities, it connects TRICONEX ESD (emergency shutdown) systems to SCADA platforms. This allows operators to remotely monitor the ESD status and receive real-time alerts if a shutdown is triggered, enabling quick responses to incidents like pipeline leaks.

In chemical processing plants, the 300656-210 links TRICONEX SIS to HMI systems. It transmits data on reactor pressures, temperatures, and valve positions, letting operators track process conditions and intervene if safety limits are breached. This helps prevent chemical spills or explosions.

In power generation facilities, the module connects TRICONEX turbine control systems to plant-wide monitoring systems via Ethernet/IP. It sends data on turbine speed, vibration, and emergency stop status, ensuring that any issues are detected and addressed before they lead to unplanned outages.

In all these fields, the TRICONEX 300656-210 ensures that critical safety data flows smoothly between systems, supporting informed decision-making and maintaining safe, efficient operations.

300656-210

Product guarantee

Our company offers a one-year quality warranty service for 300656-210, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. Our company is a leading enterprise in the industrial control industry, established in 2007, with 17 years of experience. We are an import and export trade distribution company, mainly selling major brands of industrial control parts, with many unpopular discontinued models and a large stock. We have supply channel advantages and a large number of spot items to meet customers’ urgent needs for spare parts.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: