Description

TRICONEX 2201 Product Specification

Product Overview

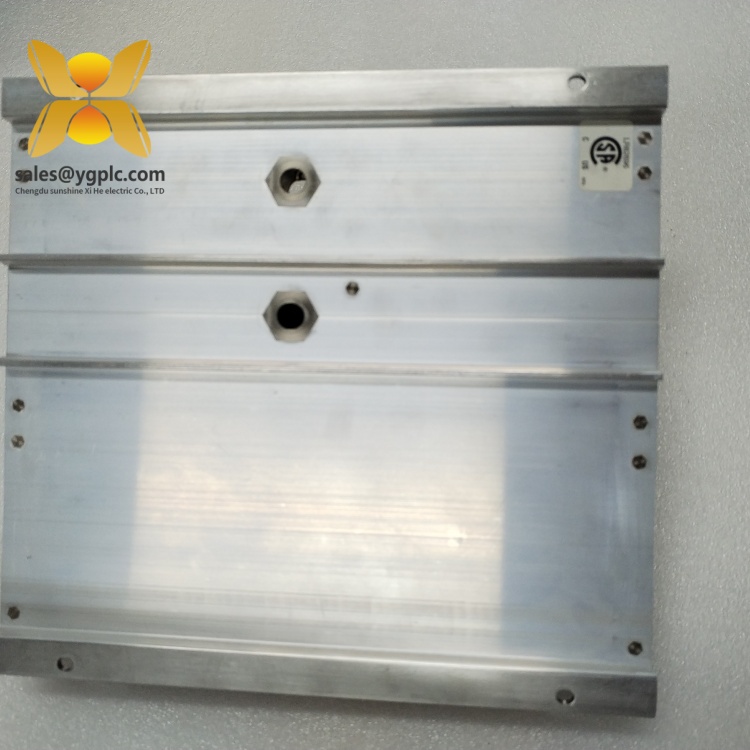

The TRICONEX 2201 is a high-performance communication module baseplate designed for TRICONEX’s Trident safety instrumented systems (SIS), serving as a critical interface for connecting industrial control systems with external devices. It supports up to two communication modules (CMs), enabling seamless integration with host computers, distributed control systems (DCS), and other Trident systems. This makes it essential for safety-critical applications where reliable data exchange and protocol compatibility are paramount.

The TRICONEX 2201 facilitates redundant communication paths and hot-swappable module replacement, ensuring continuous operation even during maintenance. It supports multiple industrial protocols, including Modbus, Ethernet/IP, and OPC, allowing flexibility in integrating with diverse automation networks. With a robust design that withstands harsh environments, the TRICONEX 2201 operates in temperatures from -40°C to +70°C and resists dust, vibration, and electromagnetic interference.

As part of TRICONEX’s Trident platform, the TRICONEX 2201 plays a vital role in maintaining system integrity. It connects directly to the main processor baseplate (MP) using dedicated interconnects, ensuring low-latency communication between modules. Whether in oil and gas refineries, chemical plants, or power generation facilities, the TRICONEX 2201 delivers secure and scalable communication to support mission-critical processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TRICONEX 2201 |

| Manufacturer | TRICONEX |

| Product Type | Communication Module Baseplate |

| Compatible Systems | TRICONEX Trident Safety Instrumented Systems (SIS) |

| Supported Modules | Up to 2 Communication Modules (CMs) per baseplate |

| Communication Protocols | Modbus RTU/ASCII, Ethernet/IP, OPC UA, TRICONEX proprietary protocols |

| Physical Dimensions | 259.08 mm (L) × 160.02 mm (W) × 78.74 mm (H) [10.2″ × 6.3″ × 3.1″] |

| Weight | 1.36 kg (3.0 lb) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail or panel-mount compatible with Trident chassis |

| Redundancy Support | Optional redundant communication connections for high availability |

| Certifications | CE, UL 508C (pending), IEC 61508 (SIL 2 compliant) |

TRICONEX 2201

Main Features and Advantages

Scalable Communication Architecture: The TRICONEX 2201 supports up to two CMs, allowing users to expand communication capabilities as needed. Each CM provides three RS-232/485 serial ports and two Ethernet ports, accommodating a mix of legacy and modern protocols. For example, it can connect to Modbus-based field devices while also integrating with Ethernet/IP networks for real-time data monitoring.

Hot-Swap Capability: Modules can be replaced without powering down the system, minimizing downtime during maintenance. This feature is critical in industries like oil and gas, where process interruptions can lead to significant losses. The TRICONEX 2201’s hot-swap design ensures continuous operation even when replacing faulty CMs.

Robust Environmental Resilience: Built to industrial standards, the TRICONEX 2201 withstands extreme temperatures, humidity, and vibration. Its rugged casing and internal shielding protect against electromagnetic interference, making it suitable for outdoor or high-noise environments such as wind farms or manufacturing plants.

Protocol Flexibility: With support for multiple protocols, the TRICONEX 2201 eliminates the need for additional gateways. It can simultaneously handle Modbus RTU for legacy equipment and Ethernet/IP for modern PLCs, streamlining system architecture and reducing complexity. This flexibility is particularly valuable in retrofitting older systems with new automation technologies.

Redundancy for High Availability: The baseplate supports redundant CM configurations, ensuring communication continuity if one module fails. Redundant paths are automatically managed by the Trident system, providing seamless failover without operator intervention. This is essential in applications like nuclear power plants, where system reliability is non-negotiable.

Related Products

- TRICONEX CM2201: A communication module that pairs with the TRICONEX 2201 to provide RS-232/485 and Ethernet connectivity. It supports SIL 3 certification for safety-critical applications.

- TRICONEX CM3201: An upgraded CM with faster data rates (up to 10 Mbps) and additional protocol support, ideal for high-speed control systems.

- TRICONEX MP Baseplate: The main processor baseplate that connects to the TRICONEX 2201 via interconnect cables, forming the core of the Trident system.

- TRICONEX 3503E: A triple modular redundant (TMR) processor module that works with the TRICONEX 2201 to execute safety logic in parallel.

- TRICONEX 3721: A digital input/output module that interfaces with field devices, complementing the TRICONEX 2201’s communication capabilities.

TRICONEX 2201

Installation and Maintenance

Pre-installation Preparations: Before installing the TRICONEX 2201, ensure the Trident chassis is powered off and grounded. Verify that the baseplate dimensions (10.2″ × 6.3″ × 3.1″) fit the available space in the control cabinet. Align the TRICONEX 2201 with the MP baseplate and secure it using the provided screws. Connect the interconnect cables between the two baseplates, ensuring proper alignment to avoid damage. Install compatible CMs into the baseplate slots, tightening the retention clips until they click into place.

Maintenance Suggestions: Regularly inspect the TRICONEX 2201 for loose connections or physical damage. Clean dust from the baseplate vents using compressed air to maintain cooling efficiency. Monitor the system’s diagnostic status via the Trident software; if a CM fails, replace it immediately using hot-swap procedures. Update firmware annually to ensure compatibility with the latest protocols and security patches. Periodically test redundant communication paths to confirm failover functionality.

Application Fields

Oil and Gas: The TRICONEX 2201 is used in offshore platforms to connect safety systems with SCADA networks, enabling real-time monitoring of wellheads and emergency shutdowns. Its redundancy features ensure continuous operation in harsh marine environments.

Chemical Processing: In petrochemical plants, the TRICONEX 2201 integrates distributed control systems (DCS) with safety instrumented systems (SIS), ensuring compliance with SIL 2/3 standards. It facilitates data exchange between PLCs and HMIs, optimizing process control and reducing downtime.

Power Generation: For thermal power plants, the TRICONEX 2201 connects turbine control systems with grid management platforms. Its protocol flexibility supports both legacy Modbus and modern Ethernet/IP, enhancing grid stability and energy efficiency.

Water Treatment: In wastewater treatment facilities, the TRICONEX 2201 links process controllers with remote telemetry units (RTUs), enabling centralized monitoring of pump stations and chemical dosing systems. Its robust design withstands corrosive environments common in water treatment plants.

TRICONEX 2201

Product Guarantee

Our company offers a one-year quality warranty service for the TRICONEX 2201, covering hardware malfunctions not caused by human factors. During the warranty period, if the TRICONEX 2201 shows abnormal performance—such as communication failures or protocol compatibility issues—we will provide replacement services. For discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, ensuring continuous support for industrial system operations.

Established in 2007, our company is a leading industrial control solutions provider with 17 years of expertise. As an import-export trade and distribution company, we specialize in offering a wide range of industrial control spare parts, including hard-to-find and obsolete models. With a large inventory of ready-to-ship products, we prioritize meeting customers’ urgent spare part requirements through efficient supply chain management.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: