Description

GE IS210AEPSG1AFC Product Specification

Product Overview

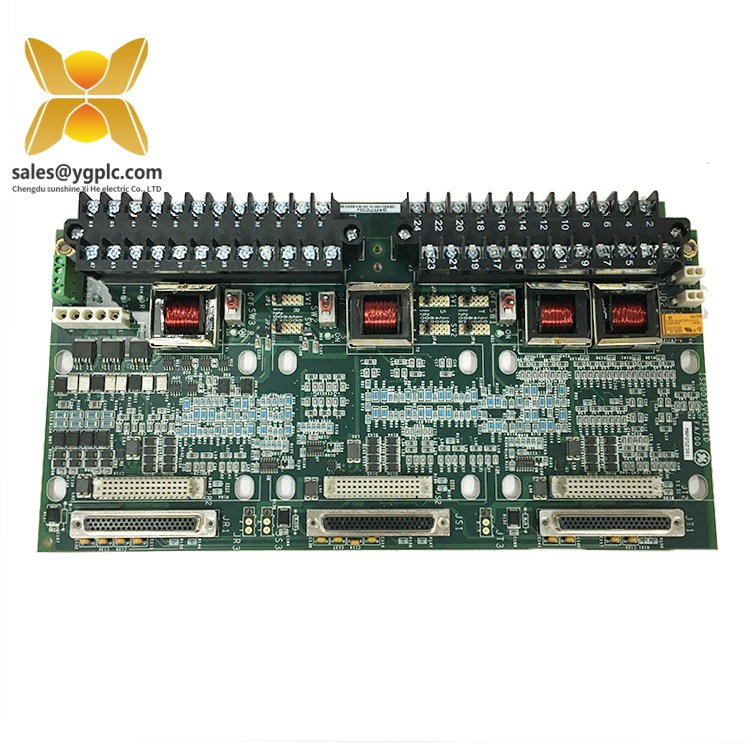

The GE IS210AEPSG1AFC is a high-performance control interface module designed for GE’s Mark VIe Turbine Control System, a cornerstone of industrial automation in power generation and heavy machinery applications. As a critical component of GE’s distributed control architecture, this module serves as the interface between field devices, human-machine interfaces (HMIs), and supervisory control systems, enabling real-time data exchange and precise operational control. The GE IS210AEPSG1AFC integrates seamlessly with other Mark VIe components, such as power supplies, I/O modules, and communication gateways, to form a robust, scalable system for monitoring and optimizing rotating equipment performance.

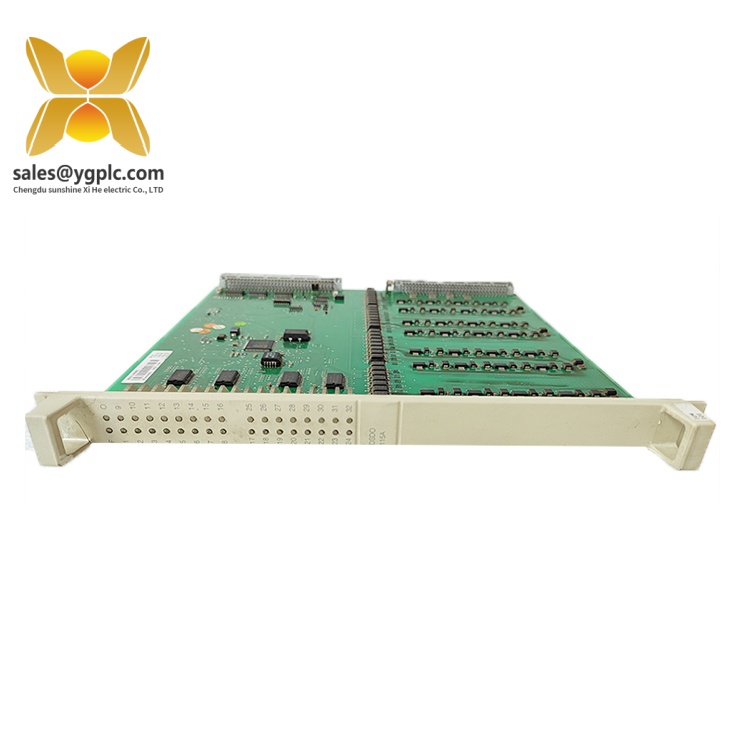

Engineered for reliability in harsh industrial environments, the GE IS210AEPSG1AFC features a rugged metal enclosure with conformal-coated circuitry to resist dust, moisture, and electromagnetic interference (EMI). Its compact design (210 mm × 150 mm × 100 mm) and lightweight construction (2.2 kg) facilitate easy installation in standard 19″ control racks, while its hot-swappable functionality allows maintenance without system downtime. The module supports multiple communication protocols, including Ethernet/IP, Modbus, and OPC UA, ensuring compatibility with modern IIoT platforms and legacy systems alike.

In automation workflows, the GE IS210AEPSG1AFC acts as a data concentrator, aggregating real-time operationaldata from sensors, actuators, and third-party devices. Its advanced diagnostics and self-monitoring capabilities alert operators to anomalies, such as voltage fluctuations or communication errors, minimizing downtime and enhancing predictive maintenance strategies. By delivering accurate, timely data to higher-level systems, this module empowers engineers to optimize energy efficiency, extend equipment lifespan, and improve safety in mission-critical environments like power plants and oil refineries.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS210AEPSG1AFC |

| Manufacturer | GE |

| Product Type | Control Interface Module |

| Communication Protocols | Ethernet/IP, Modbus RTU, OPC UA, TCP/IP |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 210 mm (W) × 150 mm (H) × 100 mm (D) |

| Weight | 2.2 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 16132 |

| Input/Output Channels | 16 digital I/O, 8 analog inputs |

| Processor | 32-bit RISC microprocessor |

| Memory | 16 MB flash, 8 MB SRAM |

Main Features and Advantages

Multi-Protocol Connectivity: The GE IS210AEPSG1AFC supports simultaneous operation of Ethernet/IP, Modbus, and OPC UA, eliminating the need for separate gateways. This versatility allows seamless integration with PLCs, HMIs, and cloud-based analytics platforms, reducing system complexity and costs 1.

Hot-Swap Capability: Designed for uninterrupted operation, the module can be replaced or upgraded without powering down the control rack. This feature is critical in 24/7 industrial settings where downtime is unacceptable 1.

Advanced Diagnostics: Built-in LED indicators and diagnostic software monitor network health, I/O status, and error rates in real time. The module also logs historical data for post-fault analysis, enabling proactive maintenance and reducing troubleshooting time 1.

Rugged Industrial Design: With an IP23-rated enclosure and vibration-resistant mounting brackets, the GE IS210AEPSG1AFC withstands extreme temperatures, humidity, and mechanical stress. Its self-shielded design minimizes EMI interference, ensuring reliable performance in dense industrial environments 1.

Scalable Performance: Part of the Mark VIe series, this module scales effortlessly with other GE components (e.g., power supplies, I/O modules) to accommodate growing automation needs. Its high-speed processor and memory architecture support rapid data processing in large-scale systems 1.

Application Fields

The GE IS210AEPSG1AFC is deployed in industries requiring precise control and real-time monitoring of high-value rotating equipment:

-

Power Generation:

- Monitors steam turbines, generators, and combustion engines in thermal and combined-cycle power plants, optimizing energy production and grid stability.

- Integrates with SCADA systems to transmit real-time vibration, temperature, and speed data for predictive maintenance of critical assets like gas turbines 1.

-

Oil and Gas:

- Controls compressors, pumps, and pipeline systems in upstream and downstream operations, ensuring safe, efficient flow rates.

- Communicates with safety instrumented systems (SIS) to enforce shutdown protocols during emergencies, enhancing operational security 1.

-

Manufacturing:

- Manages high-speed machinery in automotive and pharmaceutical plants, synchronizing production lines and improving quality control.

- Connects robotic arms and conveyor systems with enterprise resource planning (ERP) software for centralized process optimization 1.

-

Water/Wastewater Treatment:

- Regulates pump stations and chemical dosing systems, ensuring consistent water quality and compliance with environmental standards.

- Transmits data from distributed sensors to central control rooms via Modbus, enabling remote monitoring and reduced manual intervention 1.

Related Products

- GE IS200VTURH2BAC: A turbine control module for GE’s Mark VIe series, often paired with the GE IS210AEPSG1AFC to form a complete turbine protection system.

- GE IS220PAIAH1A: A redundant power supply module that ensures continuous operation of the GE IS210AEPSG1AFC in mission-critical applications.

- GE IS215UCVEH1B: A communication gateway module supporting Ethernet/IP and Profibus, enhancing network connectivity for the GE IS210AEPSG1AFC.

- GE IS210TURBH2A: A turbine health monitoring module that complements the GE IS210AEPSG1AFC by analyzing vibration and temperature data in rotating machinery.

- GE IS210VCVH1A: A voltage regulator module that stabilizes power supply fluctuations, protecting the GE IS210AEPSG1AFC from electrical surges.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS210AEPSG1AFC, ensure the following:

Before installing the GE IS210AEPSG1AFC, ensure the following:

- Verify the control rack is properly grounded to prevent electrostatic discharge (ESD) and voltage irregularities. Use a multimeter to confirm the 24 VDC power supply falls within ±10% tolerance.

- Clean the mounting slots and ensure adequate clearance (≥50 mm) around the module for airflow. Secure the module using the provided anti-vibration brackets to minimize mechanical stress during operation.

- Configure network settings (IP address, subnet mask) using GE’s Proficy software, ensuring compatibility with existing Modbus or Ethernet/IP networks.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and cleaning of dust from ventilation ports using a static-free brush.

- Functional Testing: Quarterly validation of I/O channels and communication protocols using GE’s diagnostic tools. Simulate signal inputs to verify data transmission accuracy and alarm triggers.

- Firmware Updates: Periodically update the module’s firmware via GE’s software to access security patches and new features, particularly when integrating with newer system versions.

- Component Replacement: Replace the module if exposed to prolonged extreme temperatures or physical damage. For hot-swappable units, ensure the replacement is performed within 30 seconds to maintain system continuity.

Product Guarantee

Our company provides a one-year quality warranty for the GE IS210AEPSG1AFC, covering hardware failures due to non-human factors. During the warranty period, we will replace any module exhibiting communication errors, I/O malfunctions, or performance degradation. For discontinued models like the GE IS210AEPSG1AFC, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including calibration services and repair solutions, to help maintain your system’s reliability throughout its lifecycle. Leveraging our 17-year expertise in industrial control distribution, we guarantee prompt response times and reliable supply chain solutions for even the most challenging spare parts requirements.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from GE’s official specifications and industry applications. For detailed installation guidelines, refer to the GE IS210AEPSG1AFC user manual or contact our technical support team.

GE IS200TRPAH2AHE | Mark VIe Turbine Control Relay Module | IS200TDBTH6ABC

GE IS200TPROS1CBB | Digital Input/Output (DIO) Module | IS200TDBTH6ACD

GE IS200TSVCH1AJE | Turbine Speed and Vibration Control Module | IS200TREGH1BEC

GE IS200TRPAH2AHE | Mark VIe Turbine Control Relay Module | IS200TDBTH6ABC

GE IS200VAICH1DAB | Exciter Control Module for Mark VIe Series | IS200WREAS1ADB

GE IS200VCRCH1B | Control Relay Module | IS200VPROH1BEF

GE IS200VPROH2B | Mark VIe Voltage Protection Module | IS2020RKPSG3A

GE IS200VPROH1BEF | Voltage Protection Module | IS210BPPBH2BMD

GE IS200VPWRH1AHD | Power Supply Module | IS210AEPSG1AFC

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: