Description

CCC MCP-1004 Product Specification

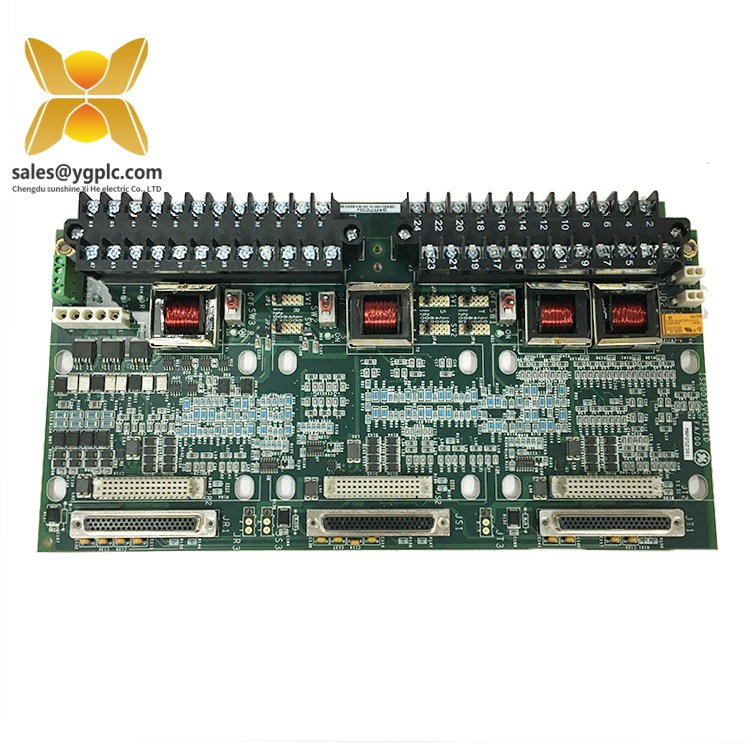

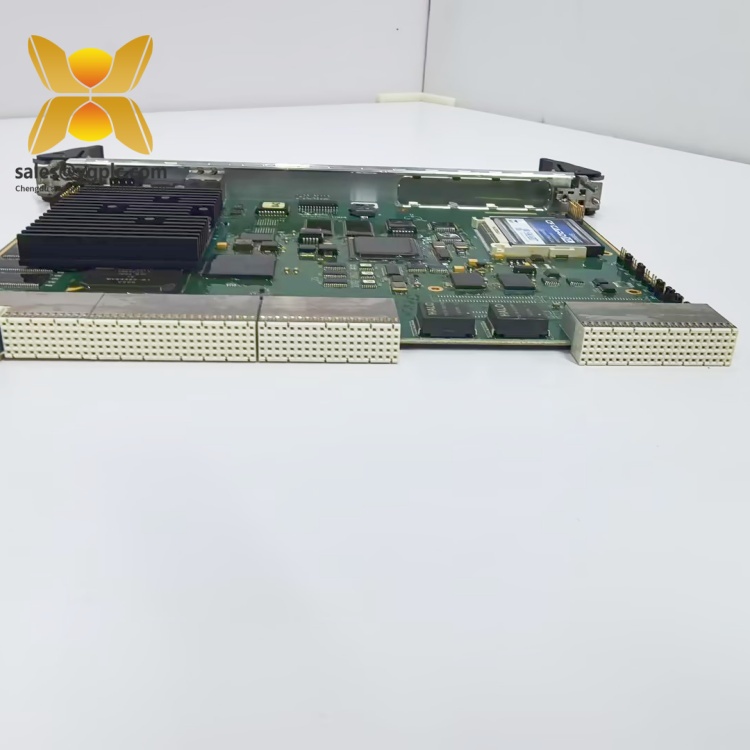

Product Overview:CCC MCP-1004

The CCC MCP-1004 is a high-performance programmable logic controller (PLC) module engineered for extreme industrial environments, particularly compressor control systems. Manufactured by Compressor Controls Corporation (CCC), a global leader in compressor automation solutions, the CCC MCP-1004 serves as the core processing unit for critical applications requiring real-time data analysis and precise control. As part of CCC’s Extreme Engineering series, this module combines robust hardware with advanced software to deliver reliable performance in oil and gas, power generation, and heavy manufacturing industries.

At its core, the CCC MCP-1004 features a 1GHz processor and 256KB of memory, enabling it to handle complex control algorithms and multitask seamlessly. It supports 24 digital I/O points and 4 analog I/O channels, making it suitable for integrating with a wide range of sensors (e.g., pressure transducers, temperature probes) and actuators (e.g., servo motors, solenoid valves) 6. The module’s dual high-speed pulse outputs further enhance its versatility, allowing direct control of stepper motors and other motion-critical devices. Designed with a rugged metal enclosure, the CCC MCP-1004 withstands extreme temperatures (-40°C to +70°C), high vibration (5–500 Hz, 2 g), and electromagnetic interference, ensuring stable operation in harsh industrial settings 12.

In automation systems, the CCC MCP-1004 acts as the brain of compressor control architectures, managing real-time data acquisition, closed-loop control, and safety interlocks. Its compatibility with CCC’s EZ-Xcaliber programming software allows engineers to customize control logic, monitor system health, and perform remote diagnostics, reducing downtime and maintenance costs. By combining high computational power with scalable I/O capabilities, the module empowers industries to optimize compressor efficiency, minimize energy consumption, and ensure compliance with safety standards such as ISO 10873 for rotating machinery.

Technical Specifications:CCC MCP-1004

| Parameter Name | Parameter Value |

|---|---|

| Product Model | CCC MCP-1004 |

| Manufacturer | Compressor Controls Corporation (CCC) |

| Product Type | Programmable Logic Controller (PLC) Module |

| Processor | 1GHz industrial-grade CPU |

| Memory | 256KB flash memory, 128MB RAM |

| I/O Configuration | 24 digital I/O, 4 analog I/O |

| High-Speed Pulse Outputs | 2 channels (200 kHz max) |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 178 mm (W) × 102 mm (H) × 254 mm (D) |

| Weight | 1.8 kg |

| Communication Protocols | Modbus RTU, Ethernet/IP (optional gateway) |

| Operating Temperature | -40°C to +70°C |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Certifications | CE, UL, CSA |

MCP-1004

Main Features and Advantages:CCC MCP-1004

Dual-Mode Signal Handling: The CCC MCP-1004 supports both analog and digital signals, offering flexibility for hybrid control systems. Its analog channels feature 16-bit resolution for precise measurement of continuous variables (e.g., compressor speed, pressure), while digital channels enable rapid response to discrete events (e.g., valve status, alarm triggers) 6. This dual capability reduces the need for multiple specialized modules, simplifying system architecture and lowering costs.

Enhanced Diagnostic Capabilities: Built-in self-test (BIST) functionality continuously monitors module health, including channel integrity, power supply stability, and thermal conditions. Faults are reported via front-panel LED indicators and through the control system’s HMI, allowing for proactive maintenance. The module also stores diagnostic logs for post-fault analysis, minimizing mean time to repair (MTTR) in critical applications 12.

Rugged Industrial Design: Constructed with a reinforced metal casing and conformal-coated PCBs, the CCC MCP-1004 resists dust, moisture, and electromagnetic interference (EMI), ensuring reliable operation in harsh environments such as offshore platforms or power plant control rooms. Its wide temperature range and vibration tolerance eliminate the need for additional environmental conditioning, reducing installation complexity 12.

Scalable Integration: The module is part of CCC’s modular Extreme Engineering platform, allowing seamless expansion of I/O capacity by adding compatible modules (e.g., CCC TMPU-1002 transition modules for communication interfaces) 4. This scalability makes it suitable for both small-scale compressor setups and large, multi-generator power plants.

Software-Defined Flexibility: Configurable through CCC’s EZ-Xcaliber software, the CCC MCP-1004 supports user-defined scaling, filtering, and alarm thresholds for each channel. Engineers can customize signal processing logic without hardware modifications, adapting the module to unique operational requirements (e.g., load-sharing algorithms, emergency shutdown protocols)

MCP-1004

Application Areas:CCC MCP-1004

The CCC MCP-1004 is purpose-built for mission-critical applications where precise control and robust performance are essential:

-

Oil and Gas:

- Compressor Stations: Monitors pressure and temperature in reciprocating compressors, activating solenoid valves for surge protection and optimizing fuel efficiency.

- Refineries: Manages turbine-driven pumps in distillation units, ensuring consistent flow rates for crude oil processing.

-

Power Generation:

- Steam/Gas Turbines: Controls turbine speed and fuel supply in combined cycle power plants, enabling real-time adjustments to maximize energy output.

- Renewable Energy: Integrates with biomass or geothermal turbine systems, ensuring stable power output and grid synchronization.

-

Industrial Manufacturing:

- Paper and Pulp Mills: Regulates steam turbine speed in power generation boilers, ensuring consistent energy supply for high-speed production lines.

- Chemical Plants: Monitors reactor temperatures and pressures via analog inputs, triggering digital outputs to activate safety interlocks in case of anomalies.

-

Marine Propulsion:

- Ship Turbines: Provides real-time feedback on shaft speed and fuel flow, supporting dynamic load balancing in naval or commercial vessels.

Related Products:CCC MCP-1004

- CCC TMPU-1002: A transition module for interfacing with extreme engineering CPUs, enabling communication with Modbus and Ethernet/IP devices 4.

- CCC MCP-2008: A higher-performance PLC module with 48 digital I/O points and advanced motion control capabilities, ideal for complex compressor systems.

- GE IS200WEMAH1AEA: A turbine control I/O module compatible with GE’s Mark VIe platform, often used in multi-vendor environments alongside the CCC MCP-1004 7.

- ABB CI871AK01 3BSE092693R1: A Profinet IO communication module for distributed control systems, enhancing connectivity in hybrid automation architectures 7.

- TRICONEX 3625: A SIL 3-rated safety controller for emergency shutdown systems, complementing the CCC MCP-1004 in safety-critical applications.

MCP-1004

Installation and Maintenance:CCC MCP-1004

Pre-installation Preparation:

Before installing the CCC MCP-1004, ensure the following:

Before installing the CCC MCP-1004, ensure the following:

- Verify the power supply voltage matches the module’s specifications (24 VDC) and that the control rack is properly grounded to prevent EMI interference.

- Use CCC’s EZ-Xcaliber software to configure I/O channels, calibration parameters, and communication protocols before mounting the module in the rack.

- Ensure adequate clearance around the module for heat dissipation, especially in high-density I/O configurations.

Maintenance Recommendations:

- Routine Inspections: Check front-panel LEDs monthly to confirm normal operation (e.g., green “Power” and “Health” indicators). Replace faulty modules immediately to avoid cascading system failures.

- Signal Calibration: Perform annual calibration of analog channels using certified test equipment to maintain measurement accuracy. Digital channels should be tested for response time using a pulse generator.

- Firmware Updates: Periodically update the module’s firmware via CCC’s software tools to address security patches or enhance compatibility with newer control system versions.

- Environmental Checks: Clean dust and debris from the module’s vents quarterly, particularly in dusty environments, to prevent overheating. Monitor ambient temperature and humidity levels using the control system’s built-in sensors.

MCP-1004

Product Warranty:CCC MCP-1004

Our company provides a one-year quality warranty for the CCC MCP-1004, covering all non-human-induced hardware defects. During the warranty period, any module exhibiting abnormal signal processing, power supply failures, or physical defects will be replaced at no cost. For discontinued models like the CCC MCP-1004, our global inventory of legacy industrial control parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services through our network of certified technicians, ensuring your critical systems remain operational long after the warranty expires.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from CCC’s official specifications and industry applications. For detailed operational guidelines, refer to the CCC MCP-1004 user manual or contact our technical support team for personalized assistance.

ALSTOM V0701596-001102 encoder

EPRO MMS3120/022-000 9100-03047-01 regulator

EPRO PR6423000-031-CN+CON021 I/O board

GE IS420UCSBH4A Counting plate

NI SBRIO-9607 Optical fiber interface board

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: