Description

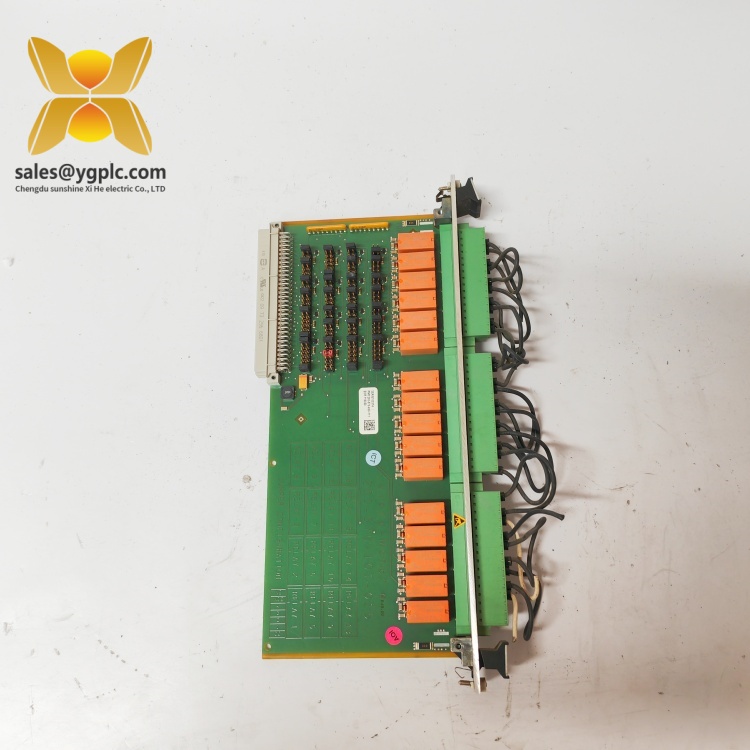

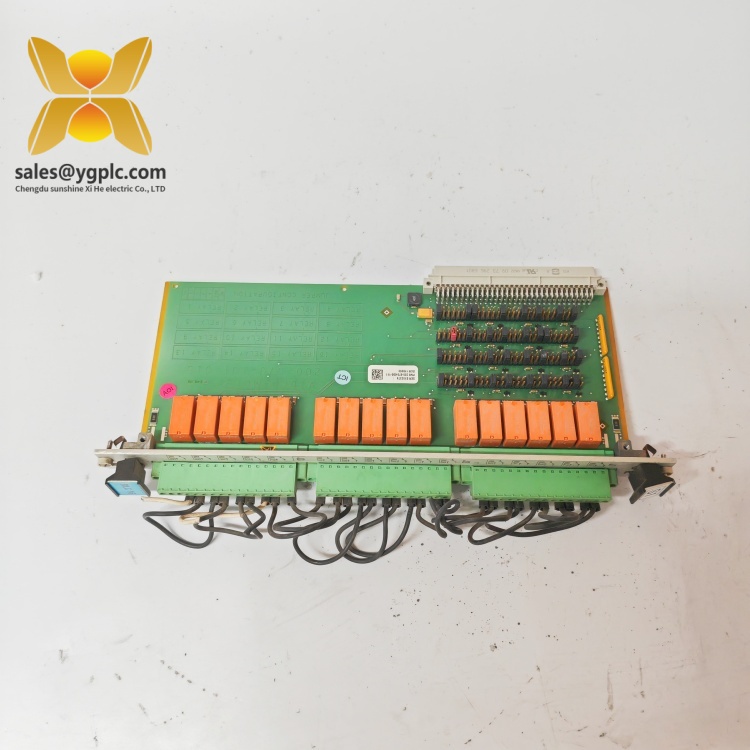

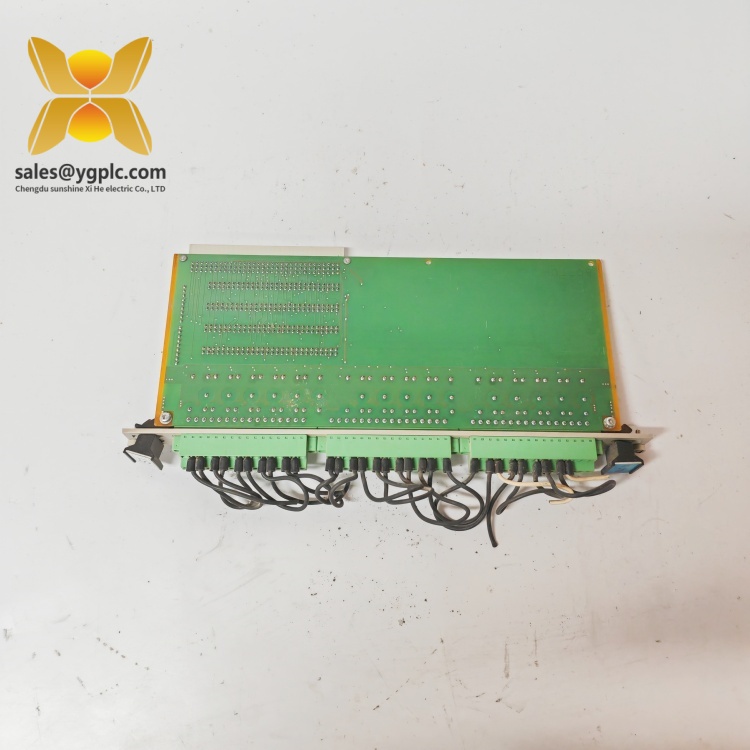

VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015 Relay Output Module

Product Overview:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

The VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015 relay output module is a critical component of the VM600 Machinery Protection System, designed to provide reliable relay-based tripping and alarm functions for rotating machinery in industrial applications. As part of the VM600 Series, this module serves as a vital link between vibration monitoring inputs and external control systems, enabling real-time protection against machinery failures.

Engineered for high-performance environments, the VM600 RLC16 features 16 independent relay outputs that can be configured to respond to various mechanical parameters, such as vibration amplitude, shaft displacement, or speed. It integrates seamlessly with other VM600 modules, such as the IOC16T input/output modules, to form a comprehensive monitoring system. The module’s dual redundant power supply and rugged construction ensure stable operation in harsh industrial conditions, while its Modbus TCP/IP communication interface allows for easy integration with SCADA and DCS systems.

In automation systems, the VM600 RLC16 plays a pivotal role in machinery health management by translating real-time vibration data into actionable control signals. Its ability to trigger alarms or shutdowns when predefined thresholds are exceeded helps prevent catastrophic failures, reducing downtime and maintenance costs. The module’s user-configurable relay settings and LED status indicators enhance operational flexibility and diagnostic efficiency, making it an essential component for predictive maintenance strategies in industries reliant on critical rotating assets.

Technical Specifications:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VM600 RLC16 200-570-000-111 200-570-101-015 |

| Manufacturer | VIBRO-METER |

| Product Type | Relay Output Module |

| Relay Channels | 16 (SPDT, 250V AC/30V DC, 5A max) |

| Power Supply | 24V DC ±15% (dual redundant) |

| Communication Protocol | Modbus TCP/IP, RS485 |

| Physical Dimensions | 177.8 mm (H) × 48.3 mm (W) × 228.6 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | 19-inch rack (3U height) |

| Country of Origin | United States |

VM600 RLC16 200-570-000-111 200-570-101-015

Key Features and Advantages:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

Redundant and Reliable Design: The VM600 RLC16 incorporates dual redundant power inputs to ensure continuous operation even if one power source fails. This feature is critical for mission-critical applications where unplanned downtime is unacceptable, such as power plants or offshore platforms.

Flexible Relay Configuration: Each of the 16 relays can be independently configured to respond to specific parameters (e.g., vibration, temperature) or system events. This flexibility allows users to tailor the module to their unique machinery protection requirements, from simple alarm notifications to complex shutdown sequences.

Seamless System Integration: With native support for Modbus TCP/IP and RS485, the VM600 RLC16 easily integrates with existing automation systems, enabling remote monitoring and control. It works in tandem with other VM600 modules, such as the VM600 COM16 communication gateway, to create a unified machinery health monitoring solution.

Real-Time Diagnostics: Built-in LED indicators provide instant visibility into relay status, power supply health, and communication connectivity. The module also supports self-diagnostic functions that detect faults such as relay contact wear or communication errors, facilitating proactive maintenance.

Compact and Rugged Construction: Despite its high channel density, the VM600 RLC16 maintains a compact 3U form factor, saving valuable rack space in control cabinets. Its industrial-grade components and -40°C to +70°C temperature tolerance make it suitable for harsh environments, including those with high vibration, dust, or humidity.

VM600 RLC16 200-570-000-111 200-570-101-015

Application Areas:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

The VIBRO-METER VM600 RLC16 relay output module is widely deployed in industries where reliable machinery protection is non-negotiable:

- Power Generation: Used in steam and gas turbines to trigger alarms or emergency shutdowns in response to abnormal vibration levels, ensuring safe and stable power production. For example, in a combined cycle power plant, the module can monitor turbine shaft vibration and automatically isolate faulty equipment to prevent cascading failures.

- Oil & Gas: Deployed in compressors, pumps, and motors across refineries and offshore platforms. The module’s ability to withstand corrosive environments and extreme temperatures makes it ideal for monitoring critical assets in these sectors, where equipment failure can lead to safety incidents or production losses.

- Manufacturing: Integrates with production lines to protect high-value machinery such as CNC machines, presses, and conveyors. By providing real-time relay outputs, it helps optimize maintenance schedules and reduce unplanned downtime in manufacturing facilities.

- Water and Wastewater: Monitors pumps and blowers in treatment plants, ensuring continuous operation by triggering alarms when vibration levels indicate potential bearing wear or misalignment.

- Aerospace and Defense: Used in test stands and rotating machinery for aerospace applications, where precise control and fail-safe protection are essential.

VM600 RLC16 200-570-000-111 200-570-101-015

Related Products:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

- VM600 IOC16T 200-565-000-013: An input/output module sets with the VM600 RLC16, providing analog and digital inputs for vibration and process variable monitoring.

- VM600 COM16 200-580-000-101: A communication module that enables Ethernet connectivity for the VM600 system, allowing the RLC16 to transmit relay status data to remote SCADA systems.

- VM600 DPM16 200-550-000-112: A display and programming module that provides local configuration and status visualization for the VM600 RLC16 and other VM600 components.

- VM600 ACC16 200-540-000-102: An acceleration sensor module that feeds vibration data to the RLC16, enabling comprehensive machinery health analysis.

- VM600 RLC32 200-570-000-222: A higher-channel variant with 32 relay outputs, suitable for larger-scale machinery protection systems requiring more control points.

- VM600 PS16 200-590-000-101: A redundant power supply module that ensures stable power delivery to the VM600 RLC16 and other VM600 modules.

- VM600 TAP16 200-530-000-103: A tachometer module that measures rotational speed, complementing the RLC16 in speed-related protection applications.

Installation and Maintenance:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

Installation Preparation:

Before installing the VM600 RLC16, ensure the control rack is properly grounded and the 24V DC power supply meets the module’s requirements. Verify that the rack has available 3U space and compatible mounting brackets. Connect the module to the rack using the provided screws, then wire the power inputs and relay outputs according to the circuit diagrams in the VM600 Series Installation Manual. Configure the module’s communication settings (e.g., IP address, Modbus ID) using the VM600 Configuration Software to ensure compatibility with the host system.

Before installing the VM600 RLC16, ensure the control rack is properly grounded and the 24V DC power supply meets the module’s requirements. Verify that the rack has available 3U space and compatible mounting brackets. Connect the module to the rack using the provided screws, then wire the power inputs and relay outputs according to the circuit diagrams in the VM600 Series Installation Manual. Configure the module’s communication settings (e.g., IP address, Modbus ID) using the VM600 Configuration Software to ensure compatibility with the host system.

Maintenance Recommendations:

- Routine Inspections: Regularly check the module’s LED indicators to confirm proper operation. Inspect relay contacts annually for signs of arcing or wear, and replace them if necessary using VIBRO-METER-certified replacement parts.

- Firmware Updates: Periodically update the module’s firmware through the VM600 system software to access new features and security patches, enhancing compatibility with evolving automation protocols.

- System Testing: Perform functional tests of all relays every six months to ensure they trigger correctly in response to simulated fault conditions. This includes verifying alarm thresholds and shutdown logic using the module’s built-in test functions.

- Environmental Cleaning: Clean the module’s ventilation slots quarterly to prevent dust accumulation, which can affect heat dissipation and lead to overheating in high-temperature environments.

VM600 RLC16 200-570-000-111 200-570-101-015

Product Warranty:VIBRO-METER VM600 RLC16 200-570-000-111 200-570-101-015

We provide a 12-month quality warranty for the VIBRO-METER VM600 RLC16 relay output module, covering hardware defects caused by non-human factors. During the warranty period, we will replace any malfunctioning module free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce spare parts, supporting continuous operation of industrial systems.

With 17 years of expertise in industrial control parts distribution, we guarantee competitive pricing, fast delivery, and reliable technical support. Contact us today to enhance your machinery protection system with the VM600 RLC16 relay output module.

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and installation guidelines.

Contact Information:

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

VIBRO-METER VM600 CPUM 200-595-067-114 Servo valve

VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017 Analog input

VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 Digital output

VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 Program module

VIBRO-METER VM600 MPC4 200-510-071-113 200-510-111-034 Ethernet

ABB UFC718AE01 HIEE300936R0001 Counting plate

FOXBORO P0926GV FBM231 Optical isolation module

GE IC695CPE400-ABAB transformer

Siemens 6DD2920-0AM0 AI card

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: