Description

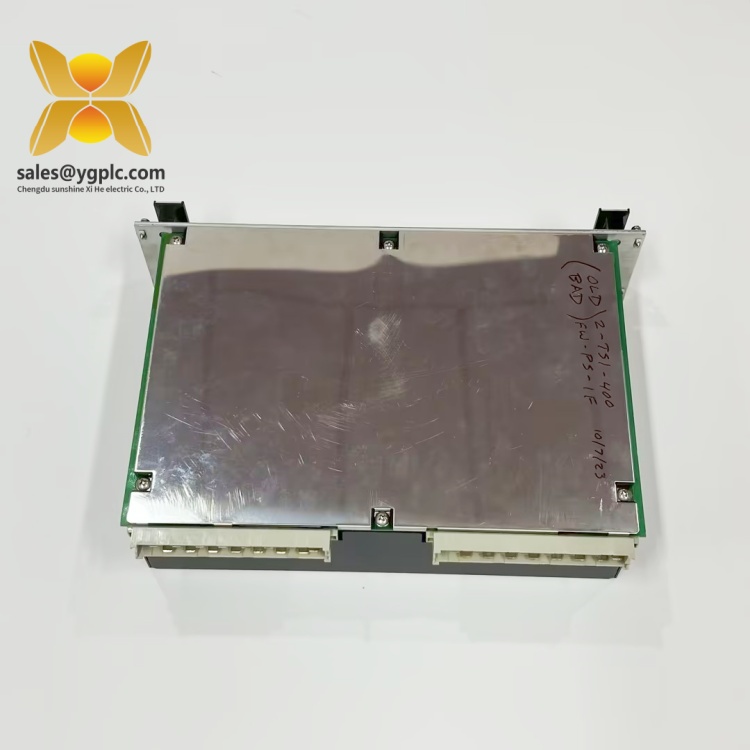

VIBRO-METER SIM-275A 200-582-500-013 Dual-Channel Vibration Monitor

Product Overview :VIBRO-METER SIM-275A 200-582-500-013

The VIBRO-METER SIM-275A 200-582-500-013 is a high-precision dual-channel vibration monitor designed for continuous health monitoring of rotating machinery in industrial automation systems. As part of VIBRO-METER’s SIM Series, this module serves as a critical component in predictive maintenance strategies, providing real-time measurement and analysis of vibration parameters to detect early signs of equipment degradation. The SIM-275A 200-582-500-013 integrates advanced signal processing algorithms and rugged hardware to ensure reliable performance in harsh environments, making it indispensable for industries reliant on the stability of turbines, compressors, and motors.

Featuring two independent measurement channels, the SIM-275A 200-582-500-013 supports simultaneous monitoring of radial vibration, axial displacement, or speed from proximity probes or seismic sensors. Each channel offers configurable alarm setpoints (warning/danger thresholds) and analog outputs (4–20 mA), enabling seamless integration with PLC, DCS, or SCADA systems. The module’s compact design (178 mm × 102 mm × 254 mm) and DIN rail mounting facilitate easy installation in control panels, while its wide operating temperature range (-40°C to +85°C) ensures durability in extreme industrial conditions.

As a key component in machinery protection systems, the VIBRO-METER SIM-275A 200-582-500-013 bridges the gap between field sensors and higher-level control systems, converting raw vibration data into actionable insights. Its built-in diagnostics continuously monitor sensor integrity and module health, reducing false alarms and minimizing downtime. By enabling proactive maintenance through precise vibration analysis, this monitor helps extend equipment lifespan, optimize operational efficiency, and prevent catastrophic failures in critical infrastructure.

Technical Specifications :VIBRO-METER SIM-275A 200-582-500-013

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SIM-275A 200-582-500-013 |

| Manufacturer | VIBRO-METER |

| Product Type | Dual-Channel Vibration and Displacement Monitor |

| Input Signals | Proximity probes (8–24 VDC), seismic accelerometers (IEPE), tachometer inputs |

| Measurement Range | Vibration: 0–500 mils (0–12.7 mm/s peak); Displacement: ±250 mils (±6.35 mm) |

| Output Signals | 2 × 4–20 mA analog, 4 × relay contacts (alarm/trip), RS-485 (Modbus RTU) |

| Power Supply | 100–240 V AC (50/60 Hz) or 24 V DC ±10% |

| Physical Dimensions | 178 mm (H) × 102 mm (W) × 254 mm (D) |

| Weight | 2.1 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | DIN rail (35 mm) or panel-mount |

| Certifications | CE, UL, API 670 |

SIM-275A 200-582-500-013

Key Features and Advantages :VIBRO-METER SIM-275A 200-582-500-013

Dual-Channel Flexibility: The SIM-275A 200-582-500-013 supports two independent measurement channels, each configurable for vibration, displacement, or speed monitoring. This versatility allows simultaneous tracking of multiple parameters on a single shaft or parallel monitoring of two separate machines, reducing hardware costs and simplifying system design.

High-Precision Signal Processing: Equipped with advanced FFT-based analysis and digital filtering, the module provides accurate vibration amplitude, frequency, and phase measurements. Its 16-bit analog-to-digital conversion ensures resolution down to 0.1 mil (0.00254 mm), enabling early detection of subtle mechanical issues like bearing wear or shaft misalignment.

Rugged Industrial Design: Built with a steel enclosure and conformal-coated circuitry, the SIM-275A 200-582-500-013 withstands high vibration (up to 10 g), shock (50 g), and electromagnetic interference (EMI). Its wide power supply range (100–240 V AC/24 V DC) and redundant power input option enhance reliability in unstable power environments.

Integrated Alarm System: The module features four user-programmable relay outputs for alarm and trip functions, with adjustable delay times (0.1–300 seconds) to prevent false triggers from transient events. LED indicators provide real-time status updates, facilitating rapid fault identification.

Easy System Integration: Compatible with Modbus RTU over RS-485, the SIM-275A 200-582-500-013 seamlessly integrates with third-party control systems. Its plug-and-play design and intuitive configuration software (VIBRO-METER Tools) reduce commissioning time, while support for industry standards like API 670 ensures compliance with machinery protection guidelines.

SIM-275A 200-582-500-013

Application Areas :VIBRO-METER SIM-275A 200-582-500-013

The VIBRO-METER SIM-275A 200-582-500-013 is widely deployed in industries where machinery reliability is non-negotiable:

- Oil & Gas: Monitors turbines, compressors, and pumps in refineries, offshore platforms, and pipelines to detect cavitation, imbalance, or misalignment, minimizing unplanned shutdowns in high-value production systems.

- Power Generation: Ensures safe operation of steam turbines, gas generators, and hydroelectric machinery by tracking vibration levels and axial movement, supporting compliance with grid stability requirements.

- Manufacturing: Protects high-speed rotating equipment such as motors, fans, and gearboxes in automotive, chemical, and food processing plants, reducing downtime caused by unexpected mechanical failures.

- Mining & Metals: Used in conveyor systems, crushers, and milling equipment to monitor bearing health and shaft dynamics, optimizing maintenance schedules in harsh, dusty environments.

Specific applications include:

- Condition-Based Maintenance (CBM): Provides real-time data for predictive maintenance programs, allowing scheduled repairs based on actual equipment condition rather than fixed intervals.

- Shutdown Protection: Triggers emergency stops via relay outputs when vibration levels exceed safe thresholds, preventing damage to critical components.

- Performance Optimization: Enables operators to fine-tune machine settings by analyzing vibration spectra, improving energy efficiency and reducing wear.

Related Products :VIBRO-METER SIM-275A 200-582-500-013

- SIM-270A 200-582-500-010: A single-channel variant of the SIM-275A 200-582-500-013, suitable for basic vibration monitoring in less critical applications.

- SIM-276A 200-582-500-014: A dual-channel model with additional temperature input capabilities, ideal for comprehensive machinery health monitoring.

- PR6423/003-031 Proximity Probe: Paired with the SIM-275A 200-582-500-013 for precise shaft displacement and vibration measurements, offering high linearity and noise immunity.

- VS-068 Seismic Accelerometer: An IEPE sensor compatible with the module’s analog inputs, designed for high-frequency vibration analysis in industrial settings.

- VM600 Machinery Protection System: A centralized monitoring platform that integrates with the SIM-275A 200-582-500-013 for multi-device management, providing advanced analytics and historical data storage.

- SIM-242A Communication Gateway: Enables Ethernet connectivity for the SIM-275A 200-582-500-013, allowing remote access to real-time data and configuration via Modbus TCP or OPC UA.

SIM-275A 200-582-500-013

Installation and Maintenance:VIBRO-METER SIM-275A 200-582-500-013

Installation Preparation:

Before installing the VIBRO-METER SIM-275A 200-582-500-013, ensure the control panel is properly grounded and ventilated. Mount the module on a DIN rail or panel using the provided brackets, leaving at least 25 mm of space between adjacent devices for heat dissipation. Connect proximity probes or accelerometers using shielded twisted-pair cables to minimize EMI, and terminate power connections with the appropriate voltage (100–240 V AC or 24 V DC). Use VIBRO-METER Tools software to configure measurement ranges, alarm setpoints, and communication parameters.

Before installing the VIBRO-METER SIM-275A 200-582-500-013, ensure the control panel is properly grounded and ventilated. Mount the module on a DIN rail or panel using the provided brackets, leaving at least 25 mm of space between adjacent devices for heat dissipation. Connect proximity probes or accelerometers using shielded twisted-pair cables to minimize EMI, and terminate power connections with the appropriate voltage (100–240 V AC or 24 V DC). Use VIBRO-METER Tools software to configure measurement ranges, alarm setpoints, and communication parameters.

Maintenance Recommendations:

- Routine Checks: Inspect the module monthly for loose connections, damaged cables, or overheating. Clean the enclosure with a dry cloth to remove dust, and verify LED status indicators for normal operation.

- Calibration: Perform annual calibration using a vibration calibrator to ensure measurement accuracy. Compare module readings against a reference sensor and adjust offsets as needed, documenting results for compliance records.

- Firmware Updates: Periodically update the module’s firmware via the RS-485 interface to access new features or bug fixes, following VIBRO-METER’s official procedures to avoid corruption.

- Spare Parts Management: Store spare SIM-275A 200-582-500-013 modules in a static-free environment at 20–25°C and <50% humidity. Rotate inventory annually to ensure shelf-life viability, and test spares periodically to confirm functionality.

SIM-275A 200-582-500-013

Product Warranty :VIBRO-METER SIM-275A 200-582-500-013

Our company provides a 12-month quality warranty for the VIBRO-METER SIM-275A 200-582-500-013, covering hardware defects under normal use. In the event of performance issues or functional failures, we offer prompt replacement services to minimize operational disruptions. For discontinued models or urgent requirements, our global supply chain network specializes in sourcing rare and obsolete industrial monitoring components, ensuring rapid delivery and reliable support. Our technical team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to keep your machinery protection systems operating at peak efficiency.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

VIBRO-METER VM600 MPC4 200-510-064-034 200-610-100-034 Digital output module

VIBRO-METER VM600 204-040-100-012 Control system power supply

VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013 Pressure transmitter

VIBRO-METER VM600 CPUM 200-595-067-114 Main frame

VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017 Expansion rack

VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 Network

BENTLY 3500/44M 140734-03 Pulse input

BENTLY 3500/54 133396-01 Analog quantity

Woodward 8237-1369 governor

Woodward 8237-1600 Input module

ABB DSDP140B 57160001-ACX Logic controller

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: