Description

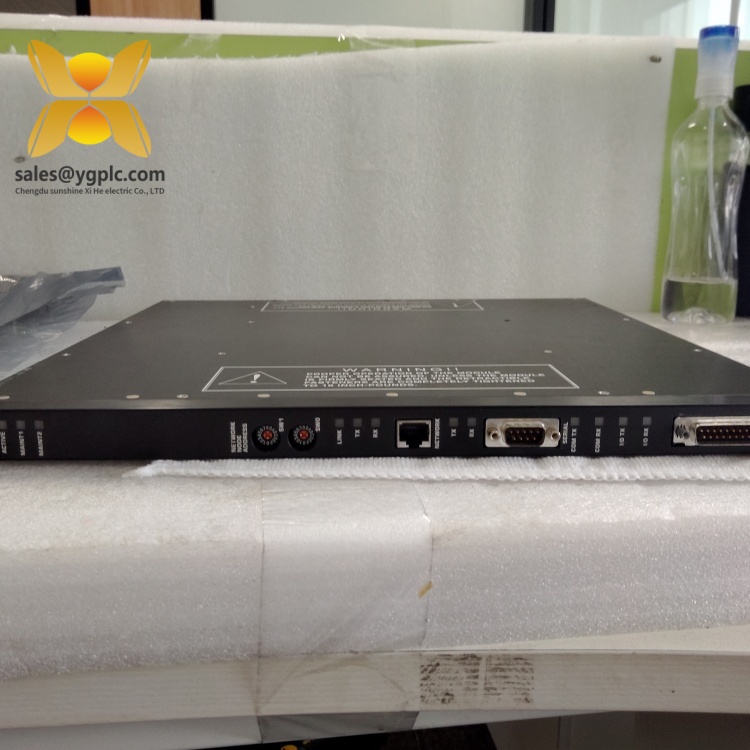

TRICONEX TX3008 TMR Main Processor Module

Product Overview

The TRICONEX TX3008 is a Triple Modular Redundancy (TMR) main processor module designed as the core of TRICONEX’s Tricon safety instrumented systems (SIS), a leading platform in industrial safety automation. This module serves as the central processing unit for safety-critical applications, executing control logic, processing data from I/O modules, and coordinating system-wide safety actions in high-risk industrial environments.

As the heart of the Tricon TMR architecture, the TRICONEX TX3008 integrates three independent processors that operate in parallel, ensuring fault tolerance through constant cross-validation of results. It communicates with Tricon I/O modules (such as TRICONEX 2101 and 2301), termination boards (like 3000678-100), and communication modules (e.g., 8111C) via the TMR backplane, enabling real-time data exchange critical for timely emergency responses, such as shutdowns during process anomalies.

Built to meet the strictest safety standards, the TRICONEX TX3008 is SIL 3 certified (IEC 61508) and operates in temperatures from -40°C to 70°C with humidity up to 95% (non-condensing). Its rugged design includes conformal coating to resist dust, moisture, and chemical exposure, ensuring reliability in harsh settings like oil refineries, chemical plants, and power stations. Though a mature model, the TRICONEX TX3008 remains vital for maintaining existing Tricon systems, offering backward compatibility with legacy I/O modules while supporting upgrades to modern field devices, thus avoiding costly full-system overhauls.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TX3008 |

| Manufacturer | TRICONEX |

| Product Type | TMR Main Processor Module (Tricon SIS) |

| Redundancy Architecture | Triple Modular Redundancy (3 independent processors) |

| Processing Speed | 333 MHz (per core) |

| Memory | 256 MB RAM, 1 GB flash storage |

| Physical Dimensions | 170 mm (L) × 110 mm (W) × 40 mm (D) |

| Weight | 0.75 kg |

| Operating Temperature | -40°C to 70°C |

| Humidity Tolerance | 5%–95% (non-condensing) |

| Power Consumption | 15 W (via backplane) |

| Safety Integrity Level | SIL 3 (IEC 61508) |

| Mounting Type | Tricon rack mount (compatible with Tricon 5000/6000 racks) |

TX3008

Related Products

- TRICONEX 2101: An 8-channel digital input module that sends sensor data (e.g., pressure switches) to the TX3008 for safety logic processing in emergency shutdown (ESD) systems.

- TRICONEX 2301: An 8-channel digital output module that executes control commands from the TX3008, such as activating shutdown valves when dangerous conditions are detected.

- TRICONEX 8111C: A redundant communication module that connects the TX3008 to SCADA systems, enabling remote monitoring of processor status and safety logic execution.

- TRICONEX 3000678-100: A termination board module that organizes wiring between field devices and I/O modules, ensuring clean signal transmission to the TX3008.

- TRICONEX 9662: A 24 V DC power supply module that delivers stable power to the TX3008 and other Tricon components, preventing voltage fluctuations that could disrupt processing.

- TRICONEX TX3010: An upgraded TMR processor with faster clock speeds than the TX3008, designed for modernized systems requiring higher processing capacity.

Main features and advantages

Triple Modular Redundancy (TMR): The TX3008 uses three identical processors running the same safety logic simultaneously. Each processor independently calculates results, and a voting circuit selects the majority outcome. If one processor fails, the other two continue operating without interruption—critical for applications like offshore oil platform ESD systems, where a single processor failure could delay a shutdown during a leak.

SIL 3 certification: Certified to IEC 61508 SIL 3, the TX3008 meets the highest safety standards, ensuring it can reliably perform safety functions in high-risk environments. This certification is mandatory for chemical plants, where a failure to detect overpressure in a reactor could lead to explosions or toxic releases.

High processing power: With a 333 MHz clock speed and 256 MB RAM, the TX3008 handles complex safety logic quickly, even with inputs from dozens of I/O modules. In a coal-fired power plant, this speed allows it to process temperature, pressure, and flow data in real time, adjusting turbine operations to prevent overspeed within milliseconds.

Broad compatibility: The module works seamlessly with all Tricon I/O modules (e.g., 2101, 2301), communication modules, and termination boards, making it easy to integrate into existing systems. This compatibility reduces upgrade costs, as users can retain legacy I/O while upgrading to the TX3008 for better processing.

Rugged industrial design: The TX3008 operates in extreme temperatures (-40°C to 70°C) and resists humidity, dust, and chemical exposure. Its conformal coating protects internal components from corrosive gases in chemical plants, ensuring a long service life—typically 10+ years in harsh settings.

Hot-swappable capability: The module can be replaced while the system runs, allowing maintenance without shutting down critical processes. In a natural gas processing plant, this means replacing a faulty processor during a scheduled window without halting production, saving thousands in downtime costs.

Installation and maintenance

Pre-installation preparations: Verify the TX3008 is compatible with your Tricon rack (e.g., Tricon 6000) and that the power supply (e.g., 9662) provides 24 V DC with ±10% tolerance. Power off the system and disconnect all power sources. Align the module with the dedicated processor slot in the rack, ensuring the backplane connectors line up, then push firmly until it clicks into place. Connect the backplane data cable to the module’s port, and secure the front panel with screws to prevent vibration-induced loosening.

Maintenance suggestions: Inspect the TX3008 monthly. Use compressed air to blow dust from the vents to prevent overheating—dust buildup can raise operating temperatures, reducing processor lifespan. Check the status LEDs: a solid green light indicates normal operation, while a flashing red light signals a processor fault. Use Tricon’s TriStation software to run diagnostic tests, which identify which of the three processors (if any) is failing. Store a spare TX3008 in a dry, cool area (10–30°C) to enable quick replacement during failures, minimizing process interruptions.

Application fields

TX3008

The TRICONEX TX3008 is widely used in industries where safety-critical processing is non-negotiable:

- Oil and gas: In onshore refineries, the TX3008 acts as the brain of the ESD system. It processes input from 2101 modules monitoring pipeline pressure and valve positions, executing logic to close valves within 50 milliseconds if pressure spikes 10% above safe limits. Its TMR design ensures this logic runs even if one processor fails.

- Chemical processing: In a fertilizer plant, the TX3008 monitors 20+ analog and digital inputs (e.g., reactor temperature, agitator speed) from I/O modules. It uses this data to maintain pH levels within a 0.2 range, activating 2301 modules to adjust chemical dosing pumps if levels drift—preventing the formation of explosive byproducts.

- Power generation: In nuclear power plants, the TX3008 controls the reactor protection system. It processes neutron flux, coolant flow, and pressure data, triggering emergency shutdowns if readings exceed thresholds. Its SIL 3 certification ensures compliance with regulatory requirements for nuclear safety.

- Water treatment: In municipal wastewater plants, the TX3008 coordinates pump operations and chemical dosing. It uses data from flow meters (connected via I/O modules) to adjust pump speeds, ensuring treatment tanks don’t overflow while minimizing energy use—all while maintaining redundant processing to avoid system downtime.

Product guarantee

Our company offers a one-year quality warranty service for the TX3008, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

Our company is a leading enterprise in the industrial control industry, established in 2007, has been 17 years. We are an import and export trade distribution company, mainly selling major brands of industrial control parts, there are many unpopular discontinued models, with a large stock. Our company has the advantage of supply channels, a large number of spot, to meet the needs of customers anxious to find spare parts. Our main PLC module, DCS card, ESD system card, vibration monitoring system card, turbine control system module, gas generator spare parts, instruments and other products distribution trade.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: