Description

Product Overview

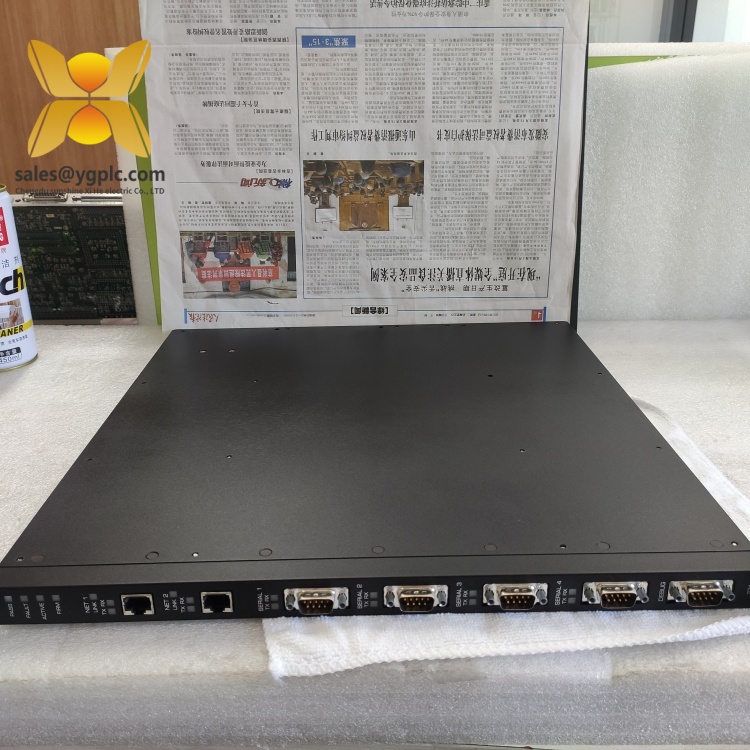

The TRICONEX 4329G is a critical communication module designed for integration within TRICONEX’s Tricon safety instrumented systems (SIS), which are widely recognized for their role in ensuring operational safety in high-risk industrial environments. As a key component of the Tricon platform, the TRICONEX 4329G facilitates seamless data exchange between the safety controller and other system components, enabling real-time monitoring and control of critical processes. Its design is centered on supporting reliable communication protocols, making it indispensable for maintaining the integrity of safety loops in complex automation setups.

The TRICONEX 4329G is part of TRICONEX’s extensive range of safety-related modules, positioning itself as a vital link in systems that demand high availability and fault tolerance. By ensuring consistent data transmission, it plays a pivotal role in preventing process failures that could lead to safety incidents, equipment damage, or production downtime. Its compatibility with existing TRICONEX systems allows for easy integration, making the TRICONEX 4329G a preferred choice for industries where system reliability is non-negotiable.

Technical Specifications

| Product model | Communication module |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Safety communication module |

| Physical dimensions | 146 mm (length) x 98 mm (width) x 42 mm (height) |

| Weight | 0.45 kg |

| Electrical specifications | 24 V DC operating voltage, 0.5 A maximum current consumption |

| Interface type | Dual Ethernet ports, RS485 serial interface |

| Communication protocol | Supports Modbus RTU/ASCII, Ethernet/IP, and TRICONEX proprietary protocols |

| Working environment | Operating temperature range: -40°C to 70°C; Relative humidity: 5% to 95% (non-condensing) |

| Place of origin | United States |

| Installation requirements | DIN rail or rack mounting, compatible with Tricon system enclosures |

| Certifications | SIL 3 compliant, meets IEC 61508 standards |

TRICONEX 4329G

Related Products

- TRICONEX 4351B: An input/output (I/O) module that works alongside the TRICONEX 4329G to collect and transmit field data. Unlike the TRICONEX 4329G, which focuses on communication, the 4351B handles analog and digital signal processing.

- TRICONEX 4210: A processor module serving as the core of the Tricon SIS. The TRICONEX 4329G connects to the 4210 to relay communication data, making them interdependent for system functionality.

- TRICONEX 4328: A predecessor to the TRICONEX 4329G with similar communication capabilities but limited protocol support. The TRICONEX 4329G offers enhanced compatibility with modern industrial protocols.

- TRICONEX 4400: A redundant power supply module that provides stable power to the TRICONEX 4329G and other Tricon modules, ensuring uninterrupted operation during power fluctuations.

- TRICONEX 4508: A digital input module that sends critical status signals to the Tricon controller. The TRICONEX 4329G facilitates the transmission of these signals to higher-level monitoring systems.

- TRICONEX 4609: An analog output module that acts on commands from the controller. The TRICONEX 4329G ensures that these commands are communicated accurately, maintaining process stability.

- TRICONEX 3625: A communication gateway that extends the TRICONEX 4329G‘s reach by connecting to non-TRICONEX systems, enabling interoperability across diverse automation architectures.

Main features and advantages

High reliability: The TRICONEX 4329G is built with a fault-tolerant design, incorporating redundant components to minimize the risk of communication failures. This redundancy ensures that even if one communication path is disrupted, the module can seamlessly switch to an alternate path, maintaining continuous data flow—a critical feature in safety-critical applications where downtime can have severe consequences.

Enhanced protocol support: Unlike older communication modules, the TRICONEX 4329G supports a wide range of industrial protocols, including Modbus RTU/ASCII, Ethernet/IP, and TRICONEX’s proprietary protocols. This versatility allows it to integrate with various third-party devices, such as PLCs, HMIs, and SCADA systems, reducing the need for additional interface modules and simplifying system architecture.

Safety certification: The TRICONEX 4329G is certified for SIL 3 compliance under IEC 61508, confirming its ability to meet the strict safety requirements of industries such as oil and gas, chemicals, and nuclear power. This certification ensures that the module contributes to maintaining the overall safety integrity of the SIS, providing users with confidence in its performance during critical operations.

Easy integration: Designed specifically for the Tricon platform, the TRICONEX 4329G integrates seamlessly with other TRICONEX modules, requiring minimal configuration during setup. Its compact form factor allows for installation in standard Tricon enclosures, saving space in control cabinets and reducing installation complexity.

Durable construction: The TRICONEX 4329G is engineered to withstand harsh industrial environments, with an operating temperature range of -40°C to 70°C and resistance to vibration and electromagnetic interference (EMI). This durability ensures reliable performance in settings where environmental conditions are often extreme, such as refineries or power plants.

TRICONEX 4329G

Installation and maintenance

Pre-installation preparations: Before installing the TRICONEX 4329G, verify that the target Tricon system is powered off to prevent electrical damage. Check the compatibility of the module with the existing system firmware; ensure the firmware version supports the TRICONEX 4329G’s protocol features. Inspect the module for physical damage, such as bent pins or cracks, which could impair functionality. Prepare the mounting location in the Tricon enclosure, ensuring it aligns with the guide rails and that there is sufficient space for wiring and heat dissipation. Confirm that the power supply (24 V DC) meets the module’s electrical requirements to avoid overloading.

Maintenance suggestions: Regular maintenance of the TRICONEX 4329G is essential to ensure long-term reliability. Conduct quarterly visual inspections to check for loose connections, dust accumulation, or signs of corrosion on the module’s terminals. Clean the module with compressed air if dust is present, taking care not to damage sensitive components. Periodically verify communication functionality by performing loop tests, where data transmission between the TRICONEX 4329G and connected devices is monitored for errors. Update the module’s firmware as recommended by TRICONEX to address potential bugs and improve performance. In case of communication failures, check the power supply and cable connections first, as these are common issues; if problems persist, consult TRICONEX technical documentation or contact support for further troubleshooting.

Application fields

The TRICONEX 4329G finds extensive application in the oil and gas industry, where it is used in upstream drilling operations, midstream pipeline monitoring, and downstream refining processes. In these settings, it facilitates communication between the Tricon SIS and critical equipment such as emergency shutdown valves (ESDVs) and pressure transmitters. By ensuring real-time data exchange, the TRICONEX 4329G helps prevent overpressure incidents, leaks, and other hazards that could lead to environmental damage or personnel injury.

In the chemical processing industry, the TRICONEX 4329G plays a key role in maintaining the safety of batch and continuous processes involving hazardous materials. It connects the SIS to devices such as flow meters, temperature sensors, and chemical storage tank monitors, enabling the controller to receive immediate updates on process conditions. This allows for rapid response to deviations from safe operating ranges, such as unexpected temperature spikes, by triggering shutdown procedures before a critical failure occurs.

The power generation sector, including fossil fuel, nuclear, and renewable energy plants, relies on the TRICONEX 4329G to ensure the safe operation of turbines, boilers, and cooling systems. In nuclear power plants, for example, the module facilitates communication between the SIS and radiation monitors, ensuring that any abnormal radiation levels are quickly relayed to the control system, which can then initiate protective measures. Similarly, in coal-fired power plants, it helps monitor combustion processes, preventing fuel leaks or excessive emissions.

Additionally, the TRICONEX 4329G is used in pharmaceutical manufacturing, where strict regulatory requirements demand precise control of production processes. It ensures that data related to temperature, pressure, and humidity in cleanrooms is accurately transmitted to the SIS, helping maintain compliance with Good Manufacturing Practices (GMP) and preventing contamination of sensitive products.

TRICONEX 4329G

Product guarantee

Our company offers a one-year quality warranty service for the TRICONEX 4329G, covering hardware malfunctions not caused by human factors. During the warranty period, if the TRICONEX 4329G shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. Our team of technical experts is available to assist with any post-purchase inquiries, ensuring that customers receive timely support for installation, troubleshooting, or compatibility issues related to the TRICONEX 4329G. We are committed to maintaining the availability and performance of the products we supply, recognizing their critical role in keeping industrial operations safe and efficient.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: