Description

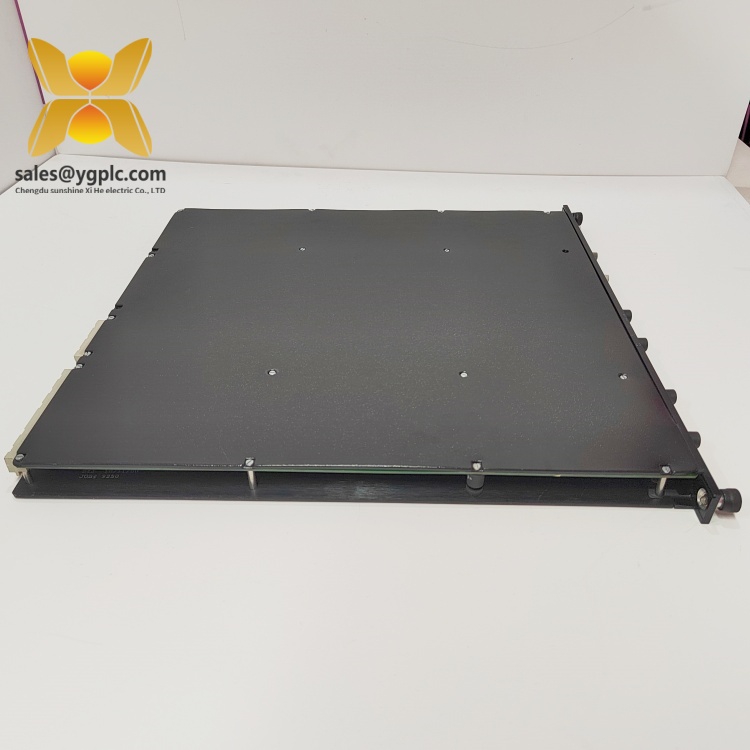

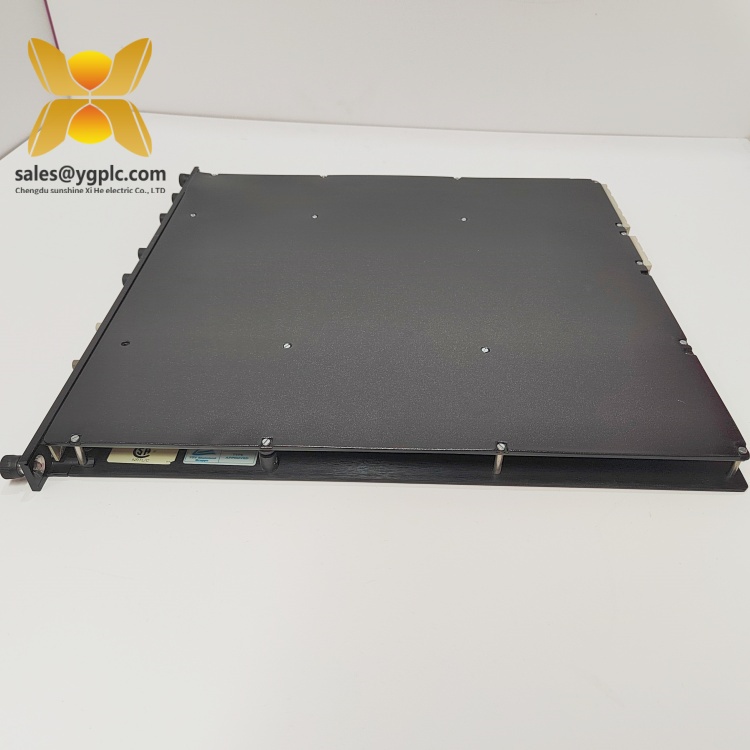

TRICONEX 4200 Tricon Controller

Product Overview

The TRICONEX 4200 is a high-reliability Tricon Controller designed as the core component of TRICONEX’s fault-tolerant safety instrumented systems (SIS). Engineered with a triple modular redundant (TMR) architecture, this controller provides deterministic control and protection for critical industrial processes in sectors such as oil & gas, chemical, and power generation. As part of the Tricon Series, the 4200 ensures seamless integration with I/O modules, communication gateways, and human-machine interfaces (HMIs), delivering fail-safe operation in environments where system downtime could lead to safety hazards or operational losses.

The TRICONEX 4200 features three independent processor modules that execute control logic in parallel, with built-in voting mechanisms to ensure data integrity and fault detection. This design achieves a single-fault tolerance, meeting the highest safety integrity levels (SIL 3 per IEC 61508 and IEC 61511). The controller supports real-time data processing, advanced control algorithms, and configurable safety logic, making it ideal for emergency shutdown systems (ESD), fire & gas detection, and critical process control applications. Its rugged enclosure and wide operating temperature range (-40°C to +70°C) ensure reliable performance in harsh industrial environments, including offshore platforms and refineries.

In automation ecosystems, the TRICONEX 4200 serves as the brain of safety-critical systems, converting field signals from sensors and actuators into precise control commands. Its compatibility with TRICONEX’s TriStation software enables intuitive configuration, diagnostics, and firmware updates, reducing engineering time and enhancing maintainability. By combining high-speed processing with inherent redundancy, the 4200 minimizes the risk of spurious trips and ensures continuous operation, making it a cornerstone of safety-driven industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 4200 |

| Manufacturer | TRICONEX |

| Product Type | Safety Controller (TMR Architecture) |

| Redundancy | Triple Modular Redundant (TMR) |

| Input Voltage | 24 V DC ±10% |

| Processing Speed | 100 MHz CPU with parallel execution |

| Memory | 512 MB flash, 256 MB RAM |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-485, Profibus DP |

| Physical Dimensions | 305 mm (H) × 229 mm (W) × 127 mm (D) |

| Weight | 4.5 kg |

| Operating Temperature | -40°C to +70°C |

| Certifications | IEC 61508 (SIL 3), IEC 61511, API 615, FM, CSA |

| Mounting | Rack-mounted (19-inch standard) |

4200

Key Features and Advantages

Triple Modular Redundancy (TMR): The 4200’s TMR architecture ensures continuous operation by voting on outputs from three independent processor modules, eliminating single points of failure. This design provides inherent fault tolerance, making it suitable for SIL 3 applications without external hardware redundancy.

High-Speed Processing: With a 100 MHz CPU and parallel processing capabilities, the controller executes complex control logic and safety algorithms in microseconds, ensuring rapid response to critical events such as overpressure or fire detection.

Hot Swappable Design: All components, including processor modules and power supplies, can be replaced without powering down the system, minimizing downtime during maintenance or component failure.

Comprehensive Diagnostics: Built-in self-diagnostic tools monitor module health, communication integrity, and power supply status, providing real-time alerts via LED indicators and the TriStation software. This proactive approach reduces mean time to repair (MTTR) and enhances system availability.

Scalable System Integration: The TRICONEX 4200 supports multiple I/O interfaces and communication protocols, enabling integration with legacy systems and modern SCADA/DCS platforms. Its modular design allows easy expansion of I/O channels or communication gateways as process requirements evolve.

Rugged Industrial Compliance: Designed to withstand extreme environmental conditions, the controller meets rigorous standards for vibration (IEC 60068-2-6), shock (IEC 60068-2-27), and electromagnetic compatibility (EMC), ensuring reliable performance in harsh industrial settings.

Application Areas

The TRICONEX 4200 is essential for safety-critical applications across industries with high-risk operations:

- Oil & Gas: Deployed in offshore rigs, refineries, and pipeline systems for emergency shutdown (ESD) systems, wellhead control, and compressor protection, ensuring compliance with API and IEC safety standards.

- Chemical Processing: Manages safety interlocks, reactor control, and hazardous material handling, preventing 失控 reactions (runaway reactions) and ensuring regulatory compliance in petrochemical plants.

- Power Generation: Controls turbine trip systems, boiler safety, and grid synchronization in thermal and nuclear power plants, minimizing the risk of catastrophic equipment failure.

- Pharmaceuticals and Food & Beverage: Ensures sterile process control and safety in manufacturing facilities, where downtime can lead to product loss and regulatory penalties.

Specific applications include:

- Fire & Gas Detection Systems: Integrates with gas sensors and fire alarms to trigger shutdowns and activate mitigation systems in real time.

- Machine Safety Systems: Protects high-risk machinery such as presses and extruders by monitoring safety switches and emergency stop signals.

- Marine and Offshore Safety: Provides fail-safe control for marine engines, ballast systems, and offshore platform safety protocols, adhering to DNV GL and SOLAS standards.

Related Products

- TRICONEX 3000 Series I/O Modules: Compatible I/O modules (e.g., 3700, 3805E) that expand the 4200’s capabilities with analog/digital inputs/outputs, thermocouple/RTD interfaces, and high-speed counting.

- TRICONEX 4351B Tricon Controller: An upgraded version with faster processing and enhanced memory, suitable for large-scale SIS applications requiring higher I/O density.

- TRICONEX 8310 Ethernet Interface Module: Enables high-speed Ethernet communication between the 4200 and SCADA systems, supporting protocols like Modbus TCP and Ethernet/IP.

- TRICONEX 9761 Power Supply Module: Redundant power supplies designed for the Tricon Series, ensuring uninterrupted operation of the 4200 during power fluctuations.

- TRICONEX 3503E Tricon Processor Module: Spare processor modules for redundancy, compatible with the 4200’s TMR architecture to maintain system integrity during module replacement.

- TRICONEX 3301E Tricon I/O Interface Module: Bridges the 4200 with field devices, providing signal conditioning and isolation for analog and digital signals.

- TRICONEX 3401E Digital Input Module: High-density digital input modules for monitoring switch states and sensor signals in safety-critical applications.

Installation and Maintenance

Pre-installation Preparations:

Before installing the TRICONEX 4200, ensure the control rack is properly grounded and ventilated. Verify power supply compatibility (24 V DC) and install redundant power modules for reliability. Use TRICONEX’s TriStation software to configure network settings, safety logic, and I/O mappings. Mount the controller in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect field devices to compatible I/O modules, using shielded cables to minimize electromagnetic interference.

Before installing the TRICONEX 4200, ensure the control rack is properly grounded and ventilated. Verify power supply compatibility (24 V DC) and install redundant power modules for reliability. Use TRICONEX’s TriStation software to configure network settings, safety logic, and I/O mappings. Mount the controller in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect field devices to compatible I/O modules, using shielded cables to minimize electromagnetic interference.

Maintenance Suggestions:

- Routine Inspections: Perform quarterly checks to validate module status via LED indicators, ensuring all three processor modules are in sync and no fault alarms are active. Clean air vents to prevent dust accumulation that could affect thermal performance.

- Firmware Updates: Regularly update the controller’s firmware using TriStation to incorporate security patches and new features, following TRICONEX’s validated procedures to avoid configuration errors.

- Redundancy Testing: Conduct annual tests of TMR functionality by simulating single-module failures, verifying that the remaining modules maintain control without disrupting operations. Document test results for compliance audits.

- Spare Parts Management: Store spare 4200 controllers and I/O modules in static-free packaging at room temperature, rotating inventory to ensure shelf-life viability. Prioritize keeping critical spares on hand for rapid replacement during emergencies.

Product Guarantee

Our company provides a 12-month quality warranty for the TRICONEX 4200, covering hardware defects under normal operating conditions. In the event of unexpected failures, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the 4200, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and safety logic optimization, delivering tailored solutions to maintain your system’s integrity and compliance.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: