Description

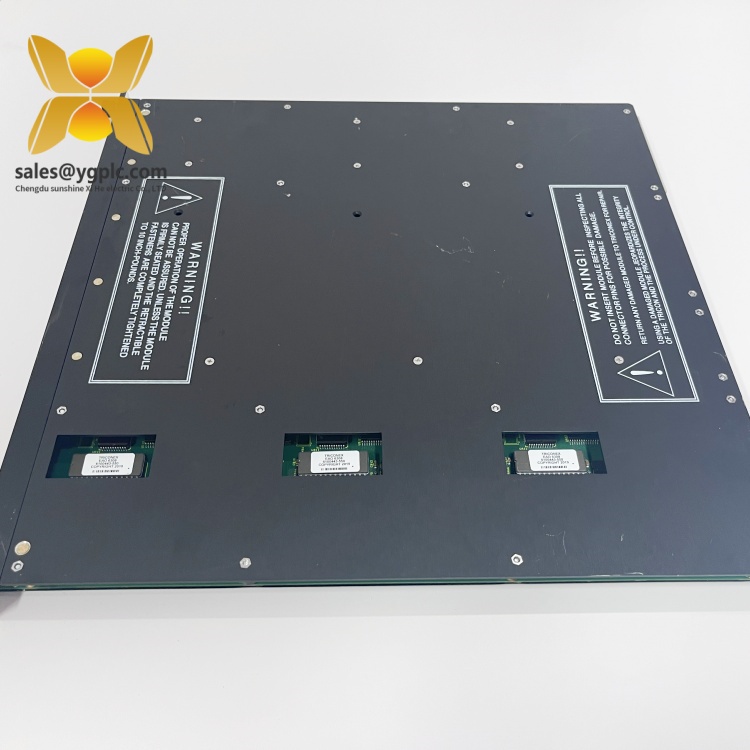

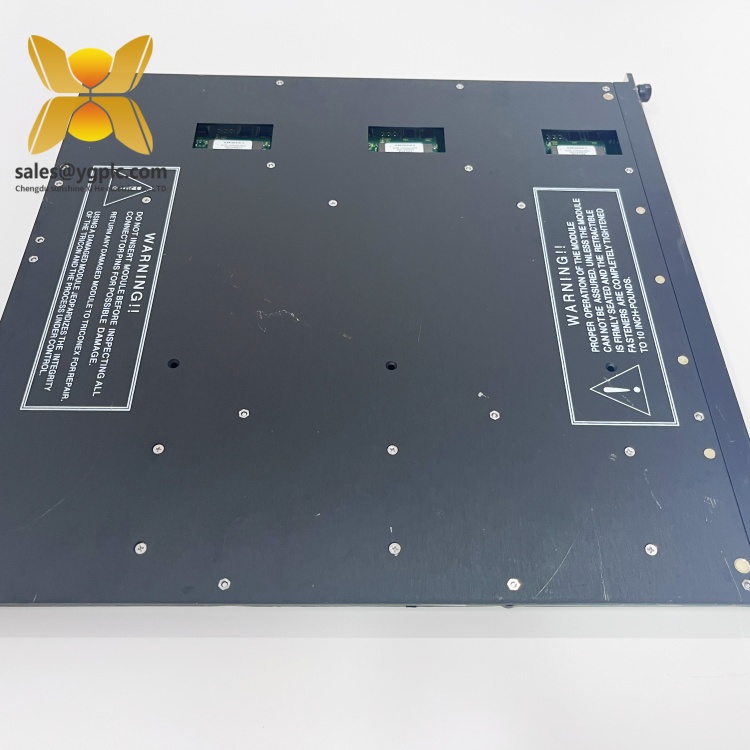

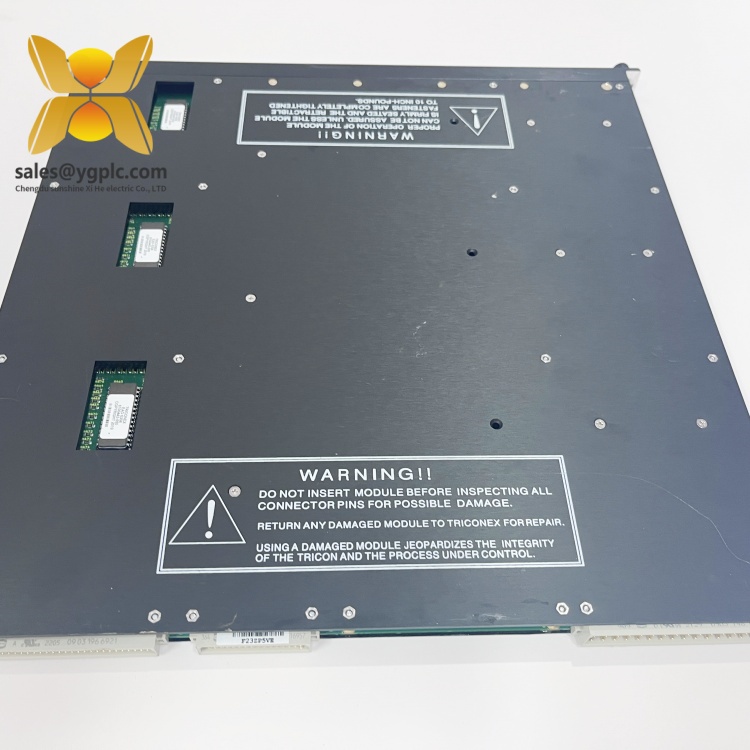

Product Overview:TRICONEX 3805H

Technical Specifications:TRICONEX 3805H

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TRICONEX 3805H |

| Manufacturer | TRICONEX |

| Product Type | 24V DC Digital Input Module (TMR) |

| Channels | 16 isolated channels |

| Input Voltage | 24V DC ±15% (sink/source compatible) |

| Physical Dimensions | 171 mm (W) × 102 mm (H) × 203 mm (D) |

| Weight | 1.2 kg |

| Redundancy | Triple Modular Redundancy (TMR) |

| Safety Integrity Level | SIL 3 (IEC 61508, IEC 61511 certified) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Installation | Rack-mounted in Tricon chassis (requires backplane connection) |

TRICONEX 3805H

Main Features and Advantages

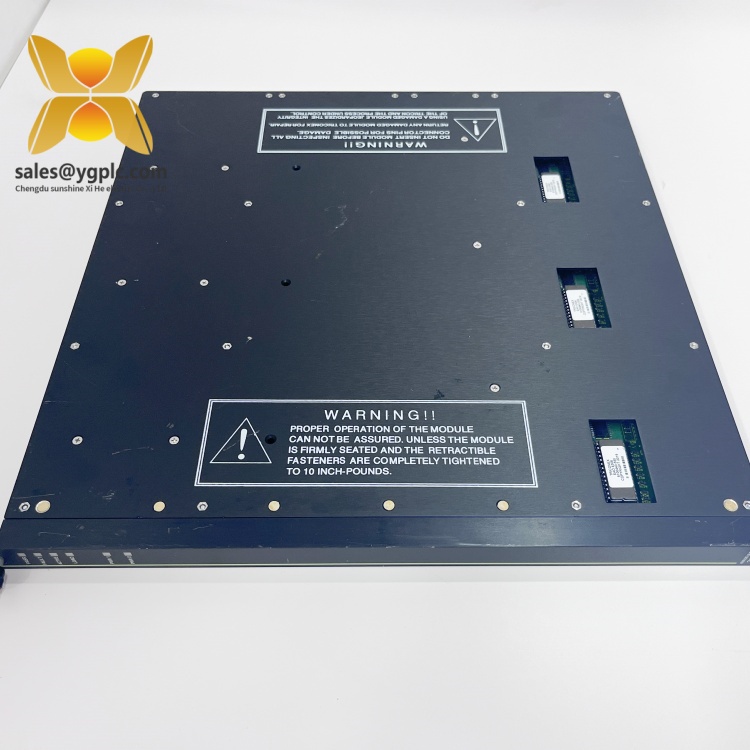

Long-Life Industrial Design: Constructed with rugged components and a conformal-coated circuit board, the TRICONEX 3805H withstands vibration, shock, and extreme temperatures, ensuring reliable operation in offshore platforms, refineries, and other harsh environments. Its long lifecycle support (typically 10+ years) makes it ideal for legacy systems requiring minimal upgrades.

TRICONEX 3805H

Application Areas

-

Oil and Gas:

- Upstream/Offshore: Monitors wellhead emergency shutdown valves, pressure switches, and safety door interlocks in offshore platforms, ensuring rapid response to leaks or equipment malfunctions.

- Downstream/Refineries: Integrates with fire and gas detection systems, activating alarms or shutdown sequences based on discrete signals from smoke detectors or gas sensors.

-

Chemical and Petrochemical:

- Manages batch processing safety interlocks, such as reactor lid position switches and pump status indicators, to prevent unauthorized operation or hazardous material releases.

- Supports SIL 3-certified ESD systems, where the module’s TMR design ensures reliable detection of overpressure or temperature excursions.

-

Power Generation:

- Monitors turbine bypass valve positions, generator breaker status, and switchgear contacts in combined cycle power plants, enabling precise coordination between control systems and field devices.

- Used in nuclear power applications for monitoring safety-related discrete inputs, compliant with stringent regulatory requirements.

-

Heavy Manufacturing:

- Controls safety barriers and emergency stop buttons in automotive assembly lines, ensuring worker safety and compliance with ISO 13849-1 performance levels.

- Monitors conveyor belt alignment switches and material level sensors in mining operations, preventing equipment damage from misalignment or overloading.

Related Products

- TRICONEX 3801H: A 125V DC digital input module with similar TMR architecture, designed for high-voltage discrete signal monitoring in legacy systems.

- TRICONEX 3802H: A 24V DC digital output module, often paired with the TRICONEX 3805H to form complete control loops, providing actuating signals to valves or motors.

- TRICONEX 3700 Series: Analog input/output modules (e.g., 3704E, 3706E) that complement the 3805H in hybrid systems requiring both discrete and continuous signal processing.

- TRICONEX 4351B: A Tricon CPU module that serves as the processing core for the safety system, integrating data from the 3805H and executing control logic.

- TRICONEX 3008: A power supply module designed for Tricon chassis, ensuring stable power delivery to the 3805H and other modules in redundant configurations.

TRICONEX 3805H

Installation and Maintenance

Before installing the TRICONEX 3805H, ensure the following:

- Verify the chassis power supply (24V DC) and backplane compatibility with the Tricon system.

- Use TRICONEX’s Tricon Engineering Workstation (TEW) software to configure channel parameters (e.g., filtering, voting logic) and assign input addresses.

- Ensure proper grounding of the chassis to mitigate EMI and protect against voltage surges.

- Routine Checks: Inspect front-panel LEDs weekly to confirm normal operation (e.g., green “Power” and “Health” indicators; amber “Fault” for channel errors).

- Signal Verification: Annually test each input channel using a calibrated signal source to ensure voltage detection accuracy and response time.

- Firmware Updates: Periodically update the module’s firmware via TEW to incorporate security patches or compatibility enhancements with newer Tricon software versions.

- Environmental Cleaning: Every six months, remove dust from the module’s vents in dusty environments to prevent overheating, using compressed air or a static-safe brush.

TRICONEX 3805H

Product Warranty

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This product description is based on technical data derived from TRICONEX’s official specifications and industry applications. For detailed installation guidelines or compliance documentation, refer to the TRICONEX 3805H user manual or contact our technical support team for personalized assistance.

TRICONEX AI2351 7400210-010 PXI module

TRICONEX AO3482 Servo drive

TRICONEX EPI3382 Servo motor

TRICONEX 8120E Industrial keyboard

TRICONEX 3511 encoder

TRICONEX 3625A regulator

TRICONEX 3009 I/O board

TRICONEX 7400213-100 Digital output module

TRICONEX DI2301 7400208-020 Digital relay output module

TRICONEX DI3301 Output module digit

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: