Description

Product Overview

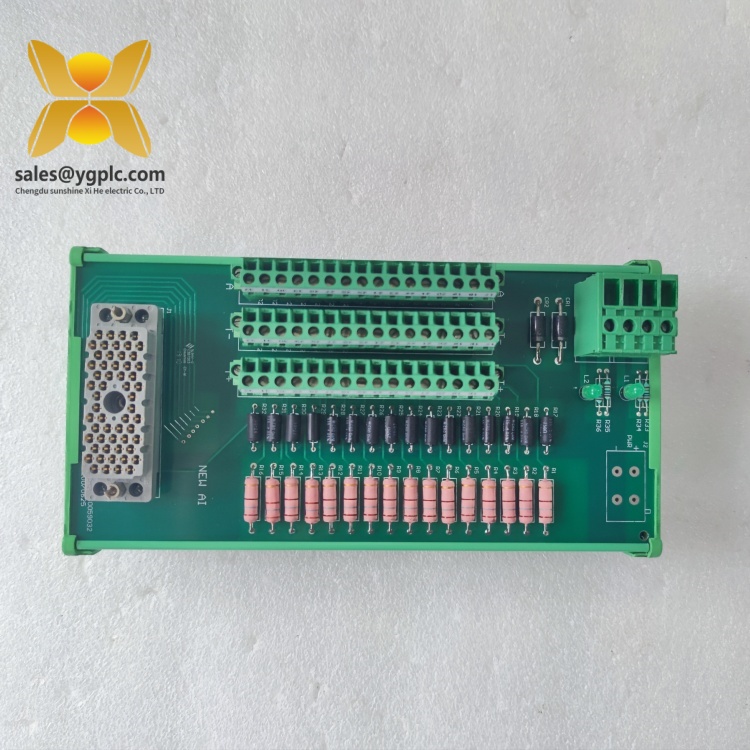

The TRICONEX 3721/9771-210 is a high-performance safety control module designed by TRICONEX, a leading brand in industrial safety instrumented systems (SIS). As a core component of the TRICONEX Tricon safety system, this module plays a critical role in enabling reliable monitoring and control of critical industrial processes. The TRICONEX 3721/9771-210 is engineered to meet the most stringent safety standards, making it an essential part of automation systems where operational integrity and hazard prevention are paramount.

This module is part of TRICONEX’s renowned 3700 series, which is widely recognized for its robust architecture and ability to deliver SIL 3 (Safety Integrity Level 3) performance. The TRICONEX 3721/9771-210 integrates advanced processing capabilities with redundant design features, ensuring continuous operation even in the event of component failures. Its positioning in automation systems is that of a safety-critical controller, bridging the gap between process sensors, actuators, and upper-level monitoring systems to prevent accidents, minimize downtime, and ensure compliance with industry regulations. By providing precise control and rapid response to abnormal conditions, the TRICONEX 3721/9771-210 delivers significant value in enhancing operational safety and efficiency across various high-risk industries.

Technical Specifications

| Product models | TRICONEX 3721/9771-210 |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Safety Control Module |

| Operating Voltage | 24 VDC ±10% |

| Maximum Current Consumption | 1.5 A @ 24 VDC |

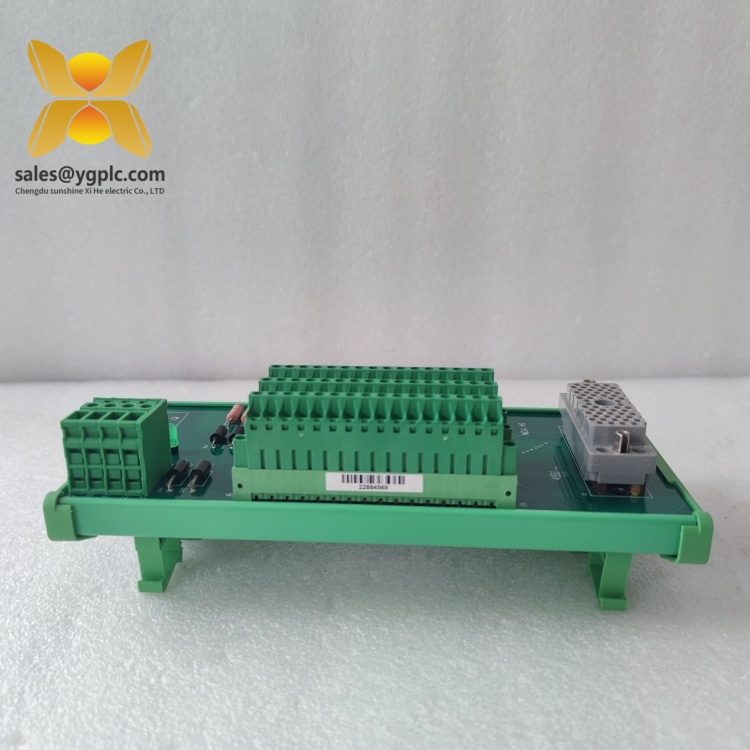

| Physical Dimensions | 165 mm (length) × 100 mm (width) × 220 mm (height) |

| Weight | 1.2 kg |

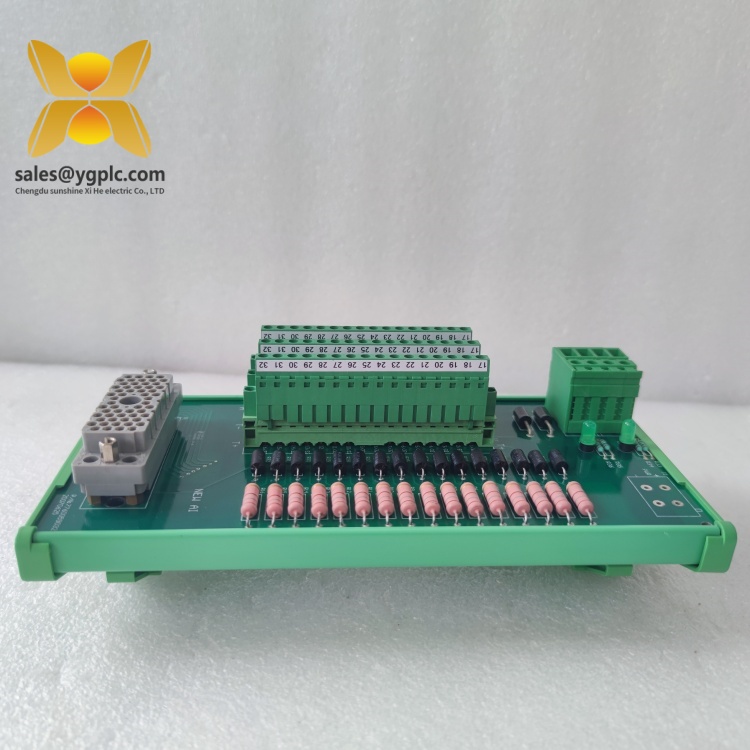

| Interface Type | Digital I/O, Backplane Communication |

| Communication Protocol | TRICONEX Proprietary Backplane Protocol |

| Working Temperature Range | 0°C to 60°C (operating); -40°C to 85°C (storage) |

| Relative Humidity | 5% to 95% non-condensing |

| Origin | United States |

3721/ 9771-210

Related Products

- TRICONEX 3720: A sibling model in the 3700 series, offering similar safety functionality with a focus on basic digital I/O control. It is ideal for applications requiring SIL 2 compliance, providing a cost-effective alternative to the TRICONEX 3721/9771-210 for less critical processes.

- TRICONEX 3722: A higher-capacity variant of the 3700 series, featuring expanded I/O channels and enhanced processing power. It complements the TRICONEX 3721/9771-210 in large-scale systems where increased connectivity is needed.

- TRICONEX 9771-110: A power supply module specifically designed to work with the TRICONEX 3721/9771-210, ensuring stable and redundant power delivery to maintain system integrity.

- TRICONEX 3805E: A communication module that enables seamless data exchange between the TRICONEX 3721/9771-210 and external systems (e.g., SCADA, DCS) via Ethernet/IP, enhancing system integration capabilities.

- TRICONEX 4351B: A redundant I/O module that works in tandem with the TRICONEX 3721/9771-210 to provide fault-tolerant input/output operations, critical for high-availability applications.

- TRICONEX 2651: An analog input module that extends the TRICONEX 3721/9771-210’s monitoring capabilities by processing continuous process variables (e.g., pressure, temperature), suitable for industries with complex sensing needs.

Main Features and Advantages

High Safety Integrity: The TRICONEX 3721/9771-210 is certified to meet SIL 3 requirements under IEC 61508, ensuring it can reliably perform safety functions in critical environments. This certification is backed by rigorous testing, confirming its ability to detect and respond to faults with minimal risk of failure, making it a trusted choice for applications where human safety and asset protection are non-negotiable.

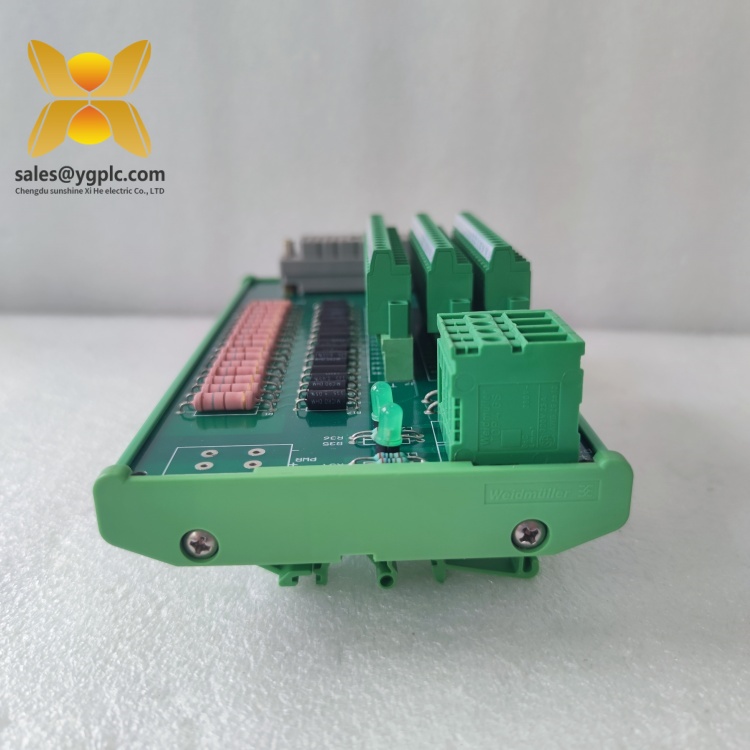

Redundant Design: A key advantage of the TRICONEX 3721/9771-210 is its built-in redundancy across critical components, including processors, power supplies, and communication paths. This redundancy eliminates single points of failure, ensuring the module continues operating even if one component malfunctions. Such design minimizes unplanned downtime, a critical factor in industries where process interruptions can lead to significant financial losses or safety hazards.

Advanced Diagnostics: The TRICONEX 3721/9771-210 incorporates comprehensive self-diagnostic features that continuously monitor internal operations and external connections. It provides real-time alerts for potential issues, such as wiring faults, sensor failures, or component degradation, allowing maintenance teams to address problems proactively before they escalate. This diagnostic capability enhances system transparency and simplifies troubleshooting, reducing the time required to resolve issues.

Easy Integration: Designed to work seamlessly with other TRICONEX components and third-party systems, the TRICONEX 3721/9771-210 supports flexible integration into existing automation architectures. Its compatibility with standard communication protocols and backplane interfaces ensures it can be easily incorporated into new installations or retrofitted into legacy systems, reducing implementation time and costs.

Durable Construction: Built to withstand harsh industrial environments, the TRICONEX 3721/9771-210 features a rugged enclosure and components rated for wide temperature ranges and high humidity. This durability ensures reliable performance in challenging conditions, such as those found in chemical plants, refineries, and power generation facilities, where environmental factors can strain equipment.

3721/ 9771-210

Installation and Maintenance

Pre-installation preparations: Before installing the TRICONEX 3721/9771-210, verify that the target system is compatible with the module’s electrical and mechanical specifications. Check the power supply to ensure it meets the 24 VDC ±10% requirement and that the backplane interface is properly configured for TRICONEX communication protocols. Inspect the installation environment to confirm temperature and humidity levels fall within the specified operating range (0°C to 60°C, 5% to 95% non-condensing). Clear the mounting area of debris and ensure the rack or enclosure is securely fastened to prevent vibration-related issues during operation.

Installation steps: Mount the TRICONEX 3721/9771-210 into the designated slot on the TRICONEX rack, ensuring it is firmly seated to establish proper backplane connections. Connect the power supply cables to the module’s terminals, following the polarity guidelines outlined in the user manual to avoid damage. Secure all wiring with appropriate connectors and strain relief to prevent accidental disconnections. After physical installation, power on the system and verify initial communication with the central controller using diagnostic software to confirm the module is recognized and functioning correctly.

Maintenance suggestions: Conduct regular visual inspections of the TRICONEX 3721/9771-210 to check for loose connections, signs of overheating (e.g., discoloration), or physical damage. Use the module’s diagnostic tools monthly to review fault logs and performance metrics, addressing any alerts promptly. Ensure firmware updates are applied as recommended by TRICONEX to maintain compatibility and security. During maintenance, power down the system or use redundant paths to avoid process interruptions, and always follow lockout/tagout procedures to ensure personnel safety.

Application Fields

The TRICONEX 3721/9771-210 finds extensive application in industries where safety-critical processes demand uncompromising reliability. In the oil and gas sector, it is deployed in upstream production facilities, midstream pipelines, and downstream refineries to monitor and control processes such as hydrocarbon separation, pressure vessel operation, and emergency shutdown systems (ESD). Here, the module’s SIL 3 certification ensures it can quickly initiate shutdowns in response to leaks, overpressure, or fire hazards, preventing catastrophic incidents and protecting personnel and assets.

In chemical processing plants, the TRICONEX 3721/9771-210 plays a vital role in managing reactions involving hazardous materials. It monitors variables such as temperature, pressure, and chemical concentrations, triggering corrective actions (e.g., valve closures, coolant injection) when deviations from safe operating ranges are detected. This capability is critical for preventing chemical spills, explosions, or toxic releases, ensuring compliance with regulations such as OSHA and REACH.

Power generation facilities, including thermal, nuclear, and renewable energy plants, rely on the TRICONEX 3721/9771-210 to safeguard turbine operations, boiler systems, and electrical distribution networks. The module’s redundant design ensures continuous monitoring of critical parameters like steam pressure and generator load, enabling rapid responses to faults that could lead to power outages or equipment damage.

Pharmaceutical and food processing industries also benefit from the TRICONEX 3721/9771-210, where it controls processes such as sterilization, mixing, and packaging. Its precision and reliability help maintain product quality and compliance with FDA and GMP standards by preventing contamination and ensuring consistent process execution. Across all these fields, the TRICONEX 3721/9771-210 serves as a cornerstone of safety automation, enabling industries to operate efficiently while minimizing risks.

3721/ 9771-210

Product Guarantee

Our company, a leading enterprise in the industrial control industry established in 2007 with 17 years of experience, provides a comprehensive quality guarantee for the TRICONEX 3721/9771-210. We offer a one-year warranty service covering all hardware malfunctions that are not caused by human factors, such as manufacturing defects or component failures. During the warranty period, if the TRICONEX 3721/9771-210 exhibits abnormal performance or functional issues, we will promptly provide replacement services to minimize downtime for our customers.

As an import and export trade distribution company specializing in industrial control spare parts, we maintain a large stock of the TRICONEX 3721/9771-210 and other TRICONEX products, including unpopular and discontinued models. This ensures we can meet urgent customer demands for spare parts, even in critical situations. Our technical support team, with deep expertise in TRICONEX systems, is available to assist with installation guidance, troubleshooting, and firmware updates, ensuring customers get the most out of their TRICONEX 3721/9771-210 modules. With reliable supply channels and a commitment to customer satisfaction, we stand behind the quality and performance of every product we provide.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: