Description

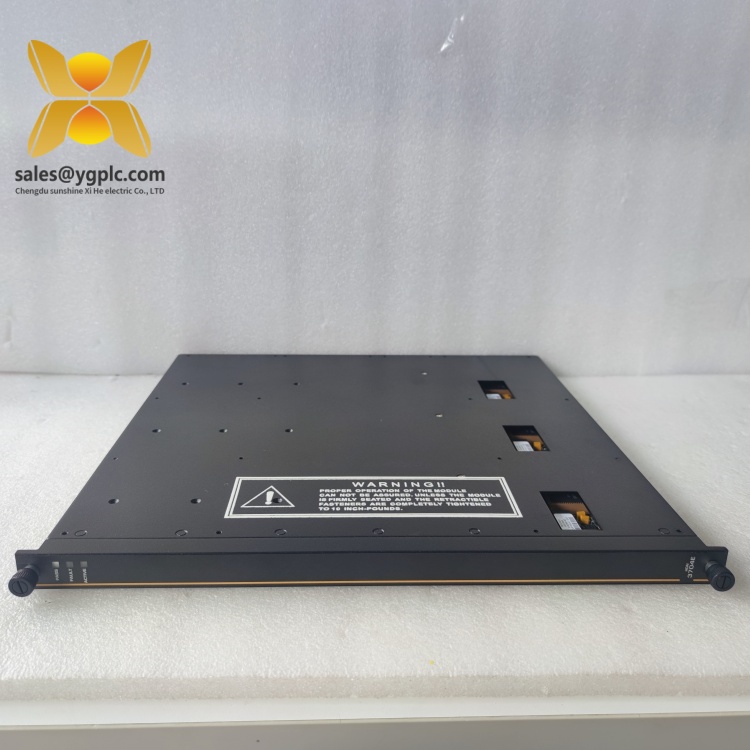

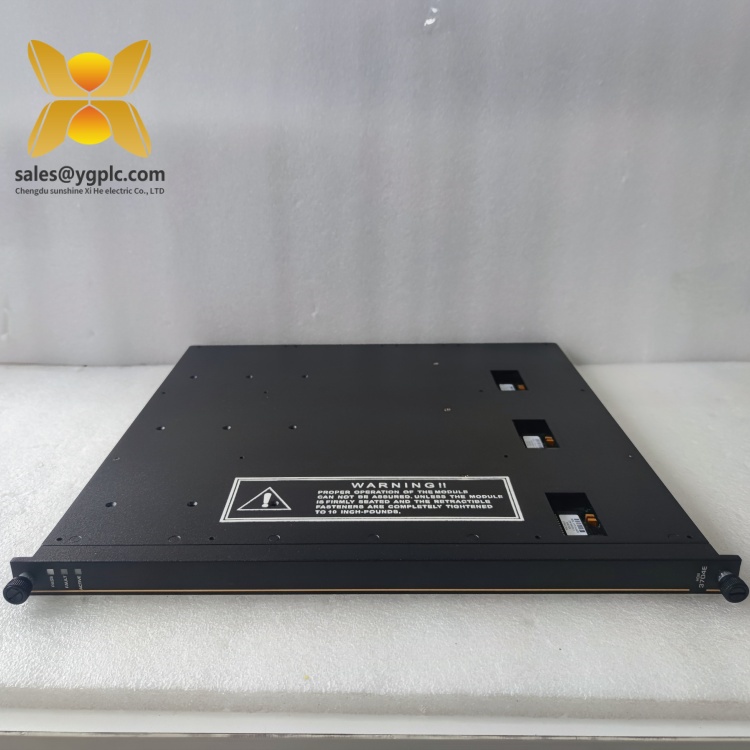

TRICONEX 3704E Analog Input Module

Product Overview

The TRICONEX 3704E is a high-performance analog input module designed for safety-critical industrial automation systems, serving as a core component in TRICONEX’s TMR (Triple Modular Redundancy) architecture. This module specializes in converting real-world analog signals—such as pressure, temperature, and flow—into digital data for processing by safety instrumented systems (SIS) and distributed control systems (DCS). As part of TRICONEX’s trusted safety I/O series, the TRICONEX 3704E is engineered to deliver precise, reliable data acquisition in environments where operational integrity directly impacts safety and productivity.

Equipped with 4 isolated input channels, the TRICONEX 3704E supports standard industrial signals like 4-20mA, making it compatible with a wide range of sensors and transmitters. Its advanced signal conditioning ensures minimal noise interference, even in harsh industrial settings, while built-in diagnostics continuously validate signal accuracy. Whether integrated into emergency shutdown (ESD) systems or critical process control loops, the TRICONEX 3704E provides the high-integrity data foundation needed for informed decision-making, helping industries meet stringent safety standards like SIL 3.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | TRICONEX 3704E |

| Manufacturer | TRICONEX |

| Product Type | Analog Input Module (Safety-Critical) |

| Input Channels | 4 isolated channels |

| Input Signal Type | 4-20mA DC (current loop) |

| Measurement Accuracy | ±0.1% of full scale |

| Isolation | Channel-to-channel: 2.5kV AC; Channel-to-backplane: 2.5kV AC |

| Communication Protocol | Modbus TCP/IP, TRICONEX Proprietary Protocol |

| Power Requirements | 24 VDC (16-32 VDC operating range) |

| Physical Dimensions | 120mm (W) x 80mm (H) x 60mm (D) |

| Weight | 0.6 kg |

| Operating Temperature | -20°C to +60°C |

| Certifications | SIL 3 (IEC 61508), CE, UL, ATEX |

| Redundancy Support | Compatible with TMR system architecture |

3704E

Key Features and Benefits

High measurement accuracy is a defining strength of the TRICONEX 3704E, with its ±0.1% full-scale precision ensuring that critical process variables are captured with minimal error. This level of accuracy is essential for applications like chemical reactor control, where small deviations can lead to safety hazards or product quality issues.

Isolation is another critical feature: each channel is electrically isolated from others and the backplane, preventing ground loops and signal interference that commonly plague industrial environments. This isolation, combined with robust signal filtering, ensures stable data transmission even in noisy settings with heavy machinery or high-voltage equipment.

The TRICONEX 3704E also excels in diagnostic capabilities. Built-in self-tests continuously monitor channel health, detecting faults such as sensor disconnections, short circuits, or signal drift. Faults are instantly reported to the system controller, enabling proactive maintenance and reducing unplanned downtime.

Integration flexibility is further enhanced by its compatibility with TRICONEX’s TMR systems and industry-standard protocols like Modbus TCP/IP. This allows seamless integration with existing DCS and SIS infrastructure, eliminating the need for extensive system overhauls when upgrading or expanding.

Application Scenarios

The TRICONEX 3704E finds critical application in industries where precise analog data acquisition is non-negotiable for safety and efficiency. In oil and gas refineries, it monitors pipeline pressure and temperature, feeding real-time data to ESD systems that trigger shutdowns during abnormal conditions to prevent leaks or explosions.

In power generation facilities, the module tracks steam pressure, turbine vibration, and coolant flow in thermal power plants, ensuring equipment operates within safe parameters. Its high accuracy makes it ideal for regulating boiler performance, where maintaining precise pressure levels directly impacts energy efficiency and system longevity.

Chemical processing plants rely on the TRICONEX 3704E to monitor reactor temperature, pH levels, and chemical flow rates. By providing reliable data to SIS, it supports automated adjustments that prevent overheating, chemical imbalances, or pressure spikes—common causes of process failures in these environments.

Pharmaceutical manufacturers also utilize the module to maintain strict control over fermentation and mixing processes, where precise temperature and pressure monitoring ensures compliance with regulatory standards for product purity and consistency.

3704E

Related Models

- TRICONEX 3703E: An 8-channel analog input module offering expanded capacity for larger-scale systems, ideal for applications requiring more sensor connections.

- TRICONEX 3705E: Specialized analog input module supporting thermocouple and RTD signals, designed for high-precision temperature measurement.

- TRICONEX 3624: Digital output module that pairs with the 3704E to create complete input-output loops in safety systems.

- TRICONEX 4200 RMX: Remote I/O module enabling the 3704E to collect data from distributed sensors in large facilities via fiber optics.

- TRICONEX 3805E: Analog output module that works with the 3704E to close control loops, converting processed data back to analog signals for actuators.

- TRICONEX 3704: Previous generation model with basic diagnostics, replaced by the enhanced 3704E with improved accuracy and fault detection.

Installation and Maintenance

Installation preparation: Before installing the TRICONEX 3704E, verify the system power supply matches the 24 VDC requirement and ensure proper grounding to prevent signal interference. Clean the DIN rail mounting area and inspect the module for physical damage. Use a torque screwdriver to secure the module to the rail with 0.8–1.2 N·m of force, ensuring a stable connection. Confirm compatibility with the host TMR controller and check that sensor wiring is correctly terminated to avoid reverse polarity issues.

Maintenance recommendations: Conduct monthly visual inspections to check for loose connections, dust accumulation, or signs of overheating. Use TRICONEX’s TriStation software to review diagnostic logs and validate channel accuracy—calibrate annually or whenever sensor drift is detected. Keep firmware updated to access the latest performance enhancements. Maintain a spare TRICONEX 3704E in inventory to minimize downtime during unexpected failures, as rapid replacement is critical for safety-critical systems.

3704E

Product Warranty

Our business focuses on distributing DCS, robot systems, and servo control modules, including PLCs, industrial PCs, and communication converters. With a global supply chain, we solve procurement challenges by offering authentic parts from multiple manufacturers, backed by competitive pricing and responsive support. We stand behind the TRICONEX 3704E’s quality and are committed to ensuring seamless integration and long-term reliability for our customers. For inquiries, contact us via standard channels for assistance.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: