Description

Product Overview

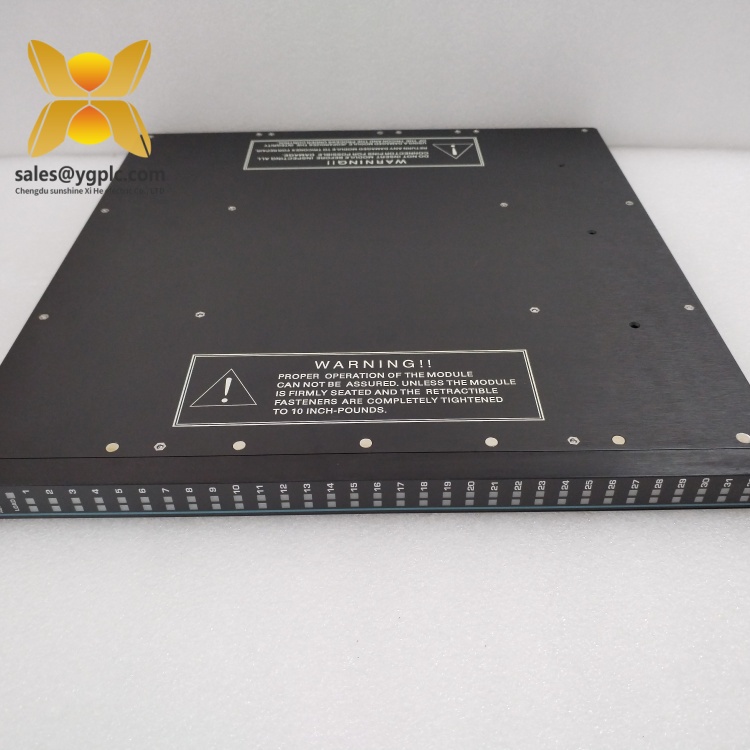

The TRICONEX 3625 is a critical communication module designed to facilitate secure and reliable data transfer within safety instrumented systems (SIS) and critical control environments. As a key component of TRICONEX’s Tricon safety system portfolio—renowned for its triple-modular redundancy (TMR) architecture—the TRICONEX 3625 serves as a bridge between the safety controller and external systems, ensuring seamless exchange of operational and diagnostic data.

The TRICONEX 3625 is engineered to maintain data integrity even in harsh industrial conditions, a feature that is paramount in applications where communication failures could compromise safety or process efficiency. Its core function includes supporting multiple industrial communication protocols, enabling interoperability with diverse automation components such as distributed control systems (DCS), human-machine interfaces (HMI), and remote monitoring tools. Whether deployed in oil refineries, chemical plants, or nuclear power facilities, the TRICONEX 3625 plays a vital role in upholding the integrity of safety-critical communication, ensuring that critical signals—such as shutdown commands or alarm statuses—are transmitted accurately and without delay. This reliability cements its position as an indispensable component in systems where failure tolerance and operational continuity are non-negotiable.

Technical Specifications

| Product model | TRICONEX 3625 |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Communication module for safety instrumented systems |

| Physical dimensions | 165 mm x 105 mm x 32 mm (length x width x height) |

| Weight | 0.5 kg |

| Input voltage | 24 V DC ±10% |

| Communication protocols | Modbus RTU, Modbus TCP/IP, Ethernet/IP, Profibus DP |

| Operating temperature range | -40°C to 70°C |

| Storage temperature range | -55°C to 85°C |

| Origin | Austin, Texas, USA |

| Interface type | 2 x Ethernet ports (10/100 Mbps), 1 x RS-485 port, 1 x Profibus DP port |

TRICONEX 3625

Related products

- TRICONEX 3624: A sibling communication module to the TRICONEX 3625, optimized for legacy systems with support for only Modbus RTU and ASCII protocols, lacking the Ethernet/IP capabilities of the 3625.

- TRICONEX 3721: An I/O module designed to work alongside the 3625 in Tricon systems, handling analog and digital input/output signals and relying on the 3625 for data transmission to the controller.

- TRICONEX 4351B: The main processor module of the Tricon SIS, which the 3625 connects to, enabling the processor to communicate with external systems for monitoring and control.

- TRICONEX 3805E: A redundant power supply module that provides stable 24 V DC power to the 3625 and other Tricon components, ensuring uninterrupted operation during power fluctuations.

- TRICONEX 3503: A high-speed communication module with fiber-optic interfaces, offering longer-distance data transmission compared to the 3625, suitable for large-scale industrial facilities.

- TRICONEX 2651: A legacy communication module replaced by the 3625, with limited protocol support and lower data transfer rates, used in older Tricon systems requiring backward compatibility.

- TRICONEX 4508: A network interface module that extends the 3625’s communication range by enabling wireless data transfer, ideal for remote assets in oil and gas fields.

Main features and advantages

The TRICONEX 3625 is distinguished by its robust support for multiple industrial communication protocols, a feature that enables seamless integration with a wide range of automation systems. By accommodating Modbus RTU, Modbus TCP/IP, Ethernet/IP, and Profibus DP, it eliminates the need for additional protocol converters, simplifying system architecture and reducing potential points of failure. This versatility is critical in complex industrial environments, where SIS must interact with DCS, HMI, and asset management systems—each often using different communication standards.

A core advantage of the TRICONEX 3625 is its focus on data integrity and security, essential for safety-critical applications. The module incorporates built-in error-checking mechanisms, such as cyclic redundancy checks (CRC), to ensure that transmitted data remains uncorrupted. It also supports encrypted communication over Ethernet/IP, preventing unauthorized access to sensitive safety data—a key requirement in industries governed by strict regulatory standards, such as chemical processing and nuclear power.

Reliability is another defining feature. The 3625 is designed to operate in extreme conditions, with a temperature range of -40°C to 70°C and resistance to vibration, electromagnetic interference (EMI), and voltage spikes. This durability ensures consistent performance in harsh environments, from desert oil fields to Arctic LNG plants, minimizing the risk of communication failures that could compromise system safety.

The module’s redundant communication paths further enhance its availability. By supporting dual Ethernet ports and failover mechanisms, it automatically switches to a backup connection if the primary link fails, ensuring uninterrupted data flow to the SIS controller. This redundancy is critical in applications where even a brief communication outage could delay a safety shutdown, leading to hazardous conditions.

Finally, the TRICONEX 3625 simplifies system maintenance through its user-friendly configuration interface. Engineers can easily set up protocols, adjust data transfer rates, and monitor communication status via a web-based dashboard, reducing commissioning time and enabling quick troubleshooting. This ease of use, combined with its broad protocol support and rugged design, makes the 3625 a cornerstone of reliable communication in safety-critical industrial systems.

TRICONEX 3625

Installation and maintenance

Pre-installation preparations: Before installing the TRICONEX 3625, verify that the Tricon safety controller is powered off to prevent electrical damage. Ensure the module slot in the controller chassis is compatible with the 3625’s dimensions (165 mm x 105 mm x 32 mm) and that the backplane connector is clean and free of debris. Check that the power supply (typically a TRICONEX 3805E) provides 24 V DC within the ±10% tolerance to avoid voltage-related malfunctions. Review the system’s communication architecture to confirm the correct wiring of Ethernet, RS-485, and Profibus DP cables, ensuring compliance with TRICONEX’s wiring guidelines for shielded cables to minimize EMI. It is also advisable to test the communication paths with a protocol analyzer before final installation to identify any potential signal interference.

Maintenance suggestions: To ensure the TRICONEX 3625 operates reliably, conduct monthly visual inspections to check for loose connections, corrosion on terminals, or dust accumulation on the module’s surface. Clean the module using compressed air to remove dust from ventilation slots, preventing overheating. Every three months, verify the integrity of communication links by monitoring data transmission logs for errors or dropouts, using the Tricon’s diagnostic software. Update the module’s firmware regularly using TRICONEX’s official tools to access the latest protocol updates and security patches. In case of communication failures, first check the physical connections and power supply; if issues persist, use the module’s built-in self-test function to diagnose internal faults. Avoid hot-swapping the 3625 during system operation, as this may disrupt safety-critical communication—schedule replacements during planned shutdowns.

Application fields

The TRICONEX 3625 is widely deployed in oil and gas refineries, where it serves as a critical link in safety instrumented systems (SIS) responsible for preventing catastrophic events such as pipeline leaks or pressure vessel explosions. In these facilities, the 3625 connects the SIS to the DCS, enabling real-time transmission of data such as pressure, temperature, and flow rates. This data is used to trigger safety actions, such as shutting down pumps or opening relief valves, when abnormal conditions are detected. The module’s support for multiple protocols ensures compatibility with the diverse range of sensors, valves, and controllers found in refineries, making it integral to maintaining safe operations.

Chemical processing plants also rely on the TRICONEX 3625 to safeguard processes involving hazardous materials. These plants often operate with strict regulatory requirements for safety and data integrity, and the 3625’s encrypted communication and error-checking features ensure compliance with standards such as IEC 61511. By facilitating secure data transfer between the SIS and emergency shutdown systems (ESD), the module ensures that toxic or flammable substance releases are prevented through timely and accurate safety responses.

Nuclear power plants, where safety is paramount, utilize the 3625 to connect their safety systems to monitoring stations. The module’s ability to operate in extreme temperatures and resist EMI is critical in these environments, where electromagnetic interference from large generators or radiation monitoring equipment could otherwise disrupt communication. The 3625 ensures that data related to reactor pressure, coolant levels, and radiation levels is transmitted reliably, supporting rapid decision-making during abnormal events.

Additionally, the TRICONEX 3625 is used in pharmaceutical manufacturing facilities, where it connects SIS to batch control systems. In these applications, it ensures that critical parameters such as temperature and pH levels in drug production are monitored continuously, and that safety interlocks (e.g., for sterilization processes) are triggered accurately, preventing product contamination and ensuring compliance with FDA regulations.

TRICONEX 3625

Product guarantee

Our company offers a one-year quality warranty service for the TRICONEX 3625, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

As a leading enterprise in the industrial control industry established in 2007, with 17 years of experience, we specialize in the import and export trade of industrial control spare parts, including a wide range of unpopular and discontinued models, backed by a large in-stock inventory. Our supply channel advantages ensure that we can meet customers’ urgent needs for spare parts, whether for PLC modules, DCS cards, ESD system components, or communication modules like the TRICONEX 3625. For inquiries or quotations, please log in to our official website, call us, leave a message, or send an email.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: