Description

Product Overview: TRICONEX 3503EN

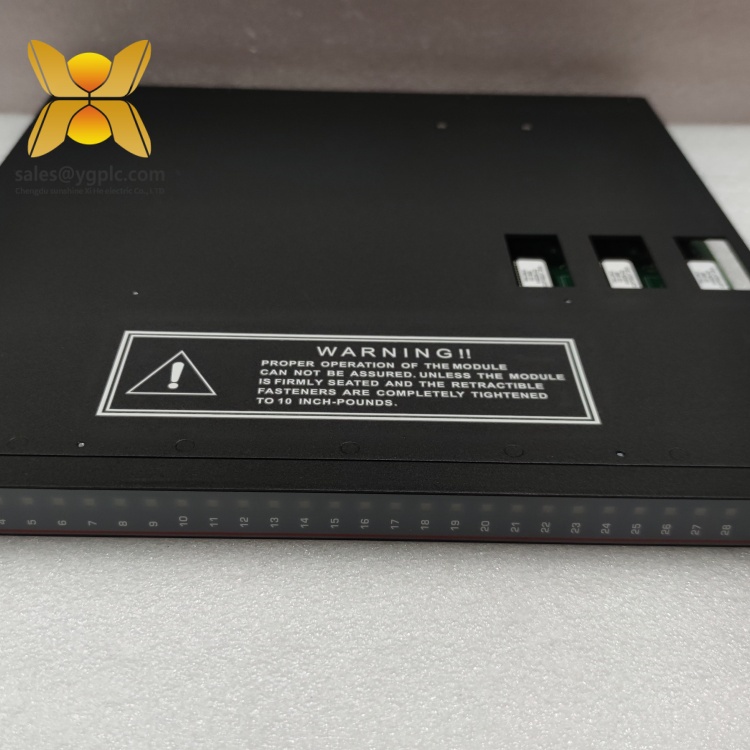

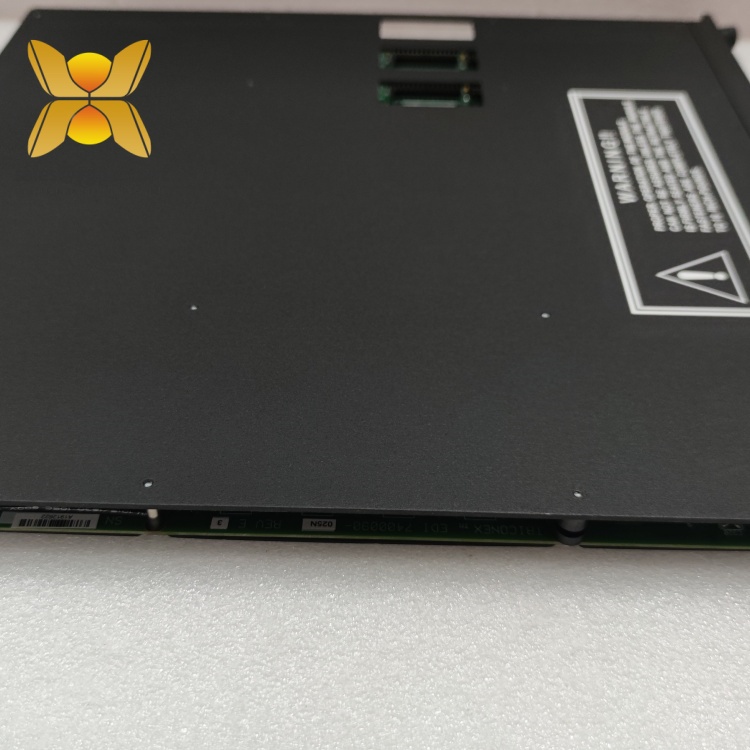

The TRICONEX 3503EN is a high-performance Triple Modular Redundancy (TMR) digital input module developed by TRICONEX, a key player in safety instrumented systems (SIS) and industrial automation. As a critical component of the TRICONEX Tricon and Tricon CX systems, the TRICONEX 3503EN is designed to acquire and process digital input signals from field devices such as limit switches, proximity sensors, and emergency stop buttons. Its primary function is to convert these discrete signals into data that can be analyzed by the system’s central processor, enabling real-time monitoring and control in safety-critical environments.

The TRICONEX 3503EN features 32 individually isolated input channels, each optimized for 24V DC operation. This configuration makes it suitable for applications requiring high channel density without compromising on isolation or reliability. As part of TRICONEX’s 3500 series, the TRICONEX 3503EN integrates seamlessly with the brand’s redundant architecture, ensuring continuous operation even if a single component fails. Its design prioritizes both safety and efficiency, making it a staple in industrial settings where downtime or signal inaccuracies could lead to operational hazards or financial losses.

Technical Specifications

| Product model | TRICONEX 3503EN |

|---|---|

| Manufacturer | TRICONEX |

| Product type | TMR digital input module |

| Input channels | 32 channels (individually isolated) |

| Nominal input voltage | 24V DC |

| Operating voltage range | 18V DC to 32V DC |

| Isolation rating | 2500V DC between channels and backplane |

| Operating temperature | -40°C to 70°C (-40°F to 158°F) |

| Physical dimensions | 101.6 mm (length) × 146.05 mm (width) × 28.58 mm (height) (4.00 in × 5.75 in × 1.125 in) |

| Weight | 230 grams (0.51 lbs) |

| Origin | United States |

| Communication protocol | TRICONEX proprietary backplane bus |

| Diagnostic capabilities | Continuous self-test, open/short circuit detection, channel fault indication |

3503EN

Related products

- TRICONEX 3501E: A 32-channel TMR digital input module designed for 115V AC/DC signals, differing from the TRICONEX 3503EN in voltage range, making it suitable for higher-voltage field devices.

- TRICONEX 3502E: A 32-channel TMR digital input module with a 48V DC rating, serving as a mid-range alternative to the TRICONEX 3503EN for systems using moderate-voltage inputs.

- TRICONEX DI3301: A 16-channel non-redundant digital input module, offering a lower-channel alternative to the TRICONEX 3503EN for applications with less stringent redundancy requirements.

- TRICONEX AI3301: An analog input module that complements the TRICONEX 3503EN by handling 4-20 mA signals, enabling the system to monitor both discrete and continuous process variables.

- TRICONEX DO3301: A digital output module designed to work alongside the TRICONEX 3503EN, converting control signals from the processor into actions for devices like solenoid valves or motor starters.

- TRICONEX 3625: A power supply module that provides stable 24V DC power to the TRICONEX 3503EN and other I/O modules, ensuring consistent performance in fluctuating power conditions.

- TRICONEX T8431: A central processing module that processes data from the TRICONEX 3503EN to execute safety logic, forming the core of the TRICONEX control system.

Main features and advantages

The TRICONEX 3503EN is distinguished by its Triple Modular Redundancy (TMR) architecture, which incorporates three independent processing paths and a voting mechanism. This design ensures that the module continues to operate correctly even if one of the three paths fails, eliminating single points of failure and enhancing system reliability. Such redundancy is critical for meeting Safety Integrity Level (SIL) 3 requirements under IEC 61508, making the TRICONEX 3503EN suitable for applications where safety is paramount.

Another key feature of the TRICONEX 3503EN is its advanced diagnostic capabilities. The module performs continuous self-tests to detect internal faults, while each channel includes open and short circuit detection. This allows for rapid identification of issues in field wiring or connected devices, reducing troubleshooting time and minimizing unplanned downtime. The 2500V DC isolation between channels and the backplane further ensures signal integrity, preventing interference from electrical noise common in industrial environments.

The TRICONEX 3503EN also offers practical benefits in terms of integration and installation. Its compact dimensions (101.6 mm × 146.05 mm × 28.58 mm) and compatibility with TRICONEX system racks allow for easy integration into space-constrained control cabinets. The 32-channel configuration provides high density, reducing the number of modules needed in large-scale systems and lowering overall installation costs. Additionally, its wide operating temperature range (-40°C to 70°C) ensures reliable performance in harsh industrial settings, from cold storage facilities to high-temperature chemical plants.

3503EN

Installation and maintenance

Pre-installation preparations: Before installing the TRICONEX 3503EN, verify that the target TRICONEX system rack is compatible with the module. Check that the 24V DC power supply meets the module’s voltage range (18V DC to 32V DC). Inspect the TRICONEX 3503EN for physical damage, such as bent pins or cracks in the casing, as these can affect performance. Ensure field wiring is properly terminated and labeled, with each of the 32 channels connected to the correct field device. Confirm that the mounting surface is clean, level, and properly grounded to prevent electrical interference.

Maintenance suggestions: To maintain optimal performance of the TRICONEX 3503EN, regularly monitor its status using TRICONEX system software to review diagnostic data and channel health. Inspect terminal block connections every three months to ensure they are tight and free from corrosion, as loose connections can cause signal loss or inaccuracies. In dusty environments, use low-pressure compressed air to clean the module’s vents and connectors, taking care not to damage sensitive components. Avoid exposing the TRICONEX 3503EN to temperatures outside its rated range (-40°C to 70°C) or excessive moisture. When handling the module, use anti-static wristbands to prevent electrostatic discharge, which can damage internal electronics. For fault resolution, refer to the TRICONEX troubleshooting manual; do not attempt to open the module, as this may void the warranty.

Application fields

The TRICONEX 3503EN is widely deployed in industries where safety and reliability are critical. In the oil and gas sector, it is used in emergency shutdown (ESD) systems to monitor signals from pressure switches and pipeline valves. By accurately detecting abnormal conditions, the TRICONEX 3503EN enables rapid activation of safety protocols, preventing leaks or explosions.

In chemical processing plants, the TRICONEX 3503EN monitors the status of reactor safety interlocks, such as temperature limit switches and door position sensors. Its ability to process 32 channels of 24V DC signals makes it ideal for managing the high number of discrete inputs in batch processing facilities, ensuring that reactions stay within safe parameters.

Power generation facilities, including nuclear and fossil fuel plants, rely on the TRICONEX 3503EN to monitor turbine trip switches, generator circuit breakers, and cooling system pumps. Its TMR architecture ensures that critical signals are not lost, even during component failures, supporting uninterrupted power supply.

Pharmaceutical manufacturing also benefits from the TRICONEX 3503EN, where it monitors cleanroom access sensors and equipment interlocks to maintain compliance with strict regulatory standards. Its high channel density and reliable performance make it a versatile solution for managing the complex safety requirements of these environments.

3503EN

Product guarantee

Our company offers a one-year quality warranty service for the TRICONEX 3503EN, covering hardware malfunctions not caused by human factors. During the warranty period, if the TRICONEX 3503EN shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

Our company is a leading enterprise in the industrial control industry, established in 2007, with 17 years of experience. As an import and export trade distribution company, we specialize in selling industrial control spare parts from major brands, including many unpopular and discontinued models, with a large stock available. Our supply channel advantages ensure that we can meet customers’ urgent needs for spare parts. Our main business includes the distribution and trade of PLC modules, DCS cards, ESD system cards, vibration monitoring system cards, steam turbine control system modules, gas generator spare parts, and instruments, among others.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: