Description

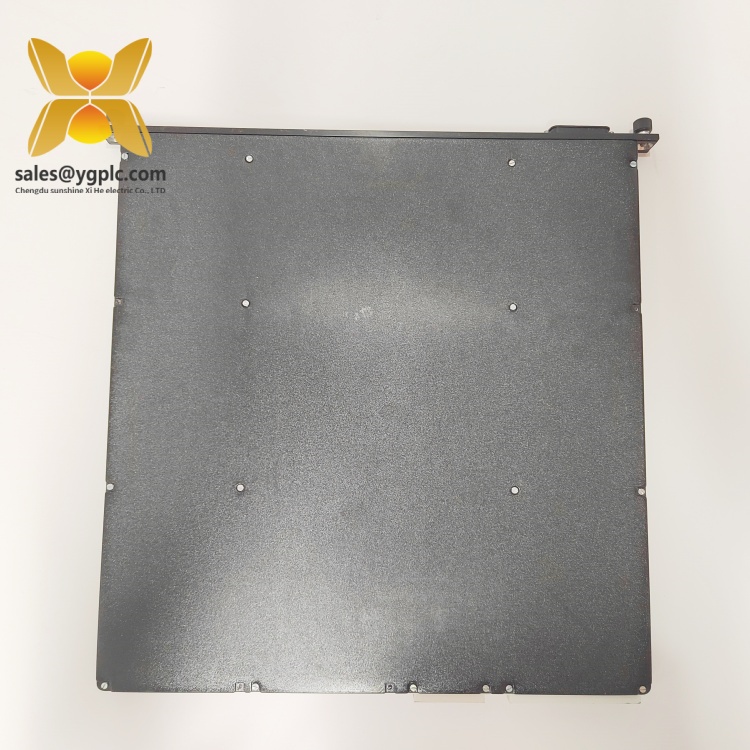

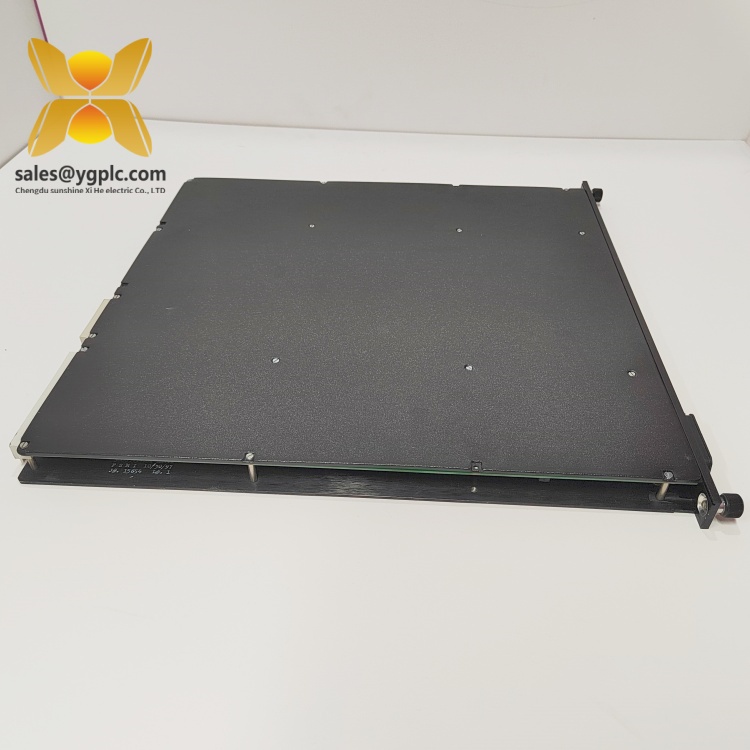

TRICONEX 3006 Digital Input Module

Product Overview: TRICONEX 3006

The TRICONEX 3006 digital input module is a high-reliability component designed for safety-critical industrial automation systems, serving as a fundamental building block of TRICONEX’s Tricon Series safety instrumented systems (SIS). Engineered to meet the rigorous demands of hazardous environments, this module provides secure and accurate acquisition of digital signals from field devices, ensuring reliable data transmission for emergency shutdown systems, critical process control, and machinery protection. The TRICONEX 3006 is specifically designed to handle discrete input signals (e.g., switch contacts, sensor states) and convert them into processed data suitable for tripping or alarming within a triple modular redundant (TMR) architecture.

As part of TRICONEX’s TMR platform, the 3006 module features a rugged design with built-in redundancy to eliminate single points of failure. It supports 24V DC input signals and includes 16 isolated channels, each capable of detecting open/closed states with diagnostic coverage exceeding 99%. The module’s compatibility with TRICONEX’s Tricon controllers enables seamless integration into distributed control systems (DCS) and safety networks, making it an essential component for industries where system uptime and safety are non-negotiable, such as oil & gas, chemical processing, and power generation.

In automation ecosystems, the TRICONEX 3006 plays a pivotal role in maintaining operational integrity by providing real-time monitoring of safety-related signals. Its compliance with IEC 61508 (SIL 3) and API 556 standards ensures it meets the highest levels of functional safety, while its hot-swappable design allows for maintenance without disrupting system operation. By combining advanced diagnostics with robust hardware, the 3006 module reduces downtime, enhances fault detection, and supports proactive maintenance strategies, ultimately optimizing the safety and efficiency of industrial processes.

Technical Specifications: TRICONEX 3006

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3006 |

| Manufacturer | TRICONEX |

| Product Type | Digital Input Module (TMR Architecture) |

| Input Voltage | 24V DC ±10% |

| Channels | 16 isolated digital inputs |

| Signal Type | Dry contacts, NPN/PNP sensors |

| Redundancy | Triple modular redundancy (TMR) |

| Diagnostic Coverage | >99% (per IEC 61508) |

| Physical Dimensions | 178 mm (H) × 102 mm (W) × 254 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -40°C to +65°C |

| Humidity | 5–95% non-condensing |

| Certifications | IEC 61508 (SIL 3), API 556, ATEX, IECEx |

| Mounting Type | TRICONEX Tricon rack (slot-compatible) |

6

3006

Main Features and Advantages: TRICONEX 3006

TMR Redundancy for Uncompromised Safety: The TRICONEX 3006 employs a triple modular redundant architecture, where each channel is independently processed and voted on by the system, ensuring fault tolerance and preventing spurious trips. This design is critical for applications requiring high availability, such as offshore platforms or nuclear facilities.

Advanced Diagnostic Capabilities: The module continuously monitors each input channel for faults (e.g., open circuits, short circuits) and provides real-time diagnostics via LED indicators and system software. This proactive approach reduces mean time to detect (MTTD) and mean time to repair (MTTR), minimizing downtime and improving system maintainability.

Industrial-Grade Durability: Built with rugged components and a metal enclosure, the 3006 module withstands harsh environmental conditions, including vibration, electromagnetic interference (EMI), and extreme temperatures. Its IP20 protection rating and compliance with industrial standards ensure reliable operation in demanding settings.

Seamless Integration: Designed for TRICONEX’s Tricon platform, the 3006 integrates seamlessly with other Tricon modules (e.g., output modules, communication gateways) and third-party systems via protocols like Modbus TCP/IP. This flexibility allows for scalable safety system designs, from small-scale installations to large, multi-plant complexes.

Hot-Swappable Design: The module can be replaced while the system is running, enabling maintenance without interrupting process operations. This feature is invaluable for industries where scheduled downtime is costly, such as continuous manufacturing or refining.

300

Application Areas: TRICONEX 3006

The TRICONEX 3006 digital input module is indispensable in industries where safety and reliability are paramount:

- Oil & Gas: Deployed in offshore rigs, refineries, and pipelines to monitor emergency shutdown (ESD) signals, valve positions, and sensor states, ensuring compliance with safety regulations and preventing catastrophic failures.

- Chemical Processing: Used to monitor safety interlocks, pressure switches, and temperature alarms in chemical plants, providing real-time data for process control and accident prevention.

- Power Generation: Integrates with turbine control systems to detect critical events (e.g., overspeed, bearing failure) and trigger protective actions, ensuring stable power production and grid safety.

- Pharmaceuticals and Food & Beverage: Supports hygienic control systems by reliably processing digital signals from sterilization equipment, batch controllers, and safety valves, maintaining compliance with regulatory standards.

- Heavy Manufacturing: Monitors machine safety signals (e.g., emergency stop buttons, door interlocks) in automotive assembly lines and metal processing facilities, reducing the risk of workplace accidents and equipment damage.

Related Products: TRICONEX 3006

- TRICONEX 3008: A 16-channel digital output module complementary to the 3006, providing redundant output signals for actuators and valves in TMR systems.

- TRICONEX 3010: A high-speed digital input module designed for fast-responding applications, such as turbine overspeed detection, with reduced signal latency.

- TRICONEX 4351: A communication module that enables Ethernet-based connectivity for the 3006, supporting integration with SCADA systems and remote monitoring platforms.

- TRICONEX 2700: A power supply module offering redundant power to the Tricon rack, ensuring stable operation of the 3006 and other components.

- TRICONEX 3503E: A processor module that works in tandem with the 3006 to execute control logic and manage system redundancy in TMR architectures.

- TRICONEX 3700: A relay output module for non-safety-related outputs, expanding the system’s flexibility in managing both critical and non-critical signals.

3006

Installation and Maintenance: TRICONEX 3006

Pre-installation Preparations:

Before installing the TRICONEX 3006, ensure the Tricon rack is properly grounded and powered. Verify that the input voltage (24V DC) matches the module’s specifications and that the rack slot is clean and free of debris. Slide the module into the designated slot, ensuring it locks into place, and connect the input cables to the terminal blocks, following TRICONEX’s wiring diagrams to avoid polarity errors. Configure the module’s address and parameters using the Tricon Configuration Studio software, ensuring compatibility with the existing system setup.

Before installing the TRICONEX 3006, ensure the Tricon rack is properly grounded and powered. Verify that the input voltage (24V DC) matches the module’s specifications and that the rack slot is clean and free of debris. Slide the module into the designated slot, ensuring it locks into place, and connect the input cables to the terminal blocks, following TRICONEX’s wiring diagrams to avoid polarity errors. Configure the module’s address and parameters using the Tricon Configuration Studio software, ensuring compatibility with the existing system setup.

Maintenance Recommendations:

- Routine Inspections: Regularly check the module’s LED indicators to confirm proper operation and monitor for fault messages. Clean the enclosure with a dry cloth to prevent dust accumulation that could affect heat dissipation.

- Functional Testing: Perform quarterly loop tests to verify that each input channel responds correctly to simulated signals. Use TRICONEX’s diagnostic tools to validate channel integrity and ensure compliance with safety requirements.

- Firmware Updates: Periodically update the module’s firmware to access the latest features and security patches, using TRICONEX’s official software to maintain system compatibility.

- Spare Parts Management: Keep a spare 3006 module in stock, pre-configured with the same parameters as the installed unit, to minimize downtime in case of failure. Leverage our global supply chain for quick delivery of certified replacements.

3006

Product Guarantee: TRICONEX 3006

Our company provides a 12-month quality warranty for the TRICONEX 3006 digital input module, covering hardware defects and non-human-induced malfunctions. During the warranty period, we will replace any module that fails to meet performance specifications, ensuring minimal disruption to your operations. For discontinued models or urgent repair needs, our extensive inventory and global logistics network enable rapid fulfillment of spare parts, even for legacy systems.

With 17 years of expertise in industrial control distribution, we are committed to delivering reliable, safety-certified components like the TRICONEX 3006. Our team of technical experts is available to assist with installation, configuration, and troubleshooting, ensuring your safety system operates at peak efficiency. Contact us today to discuss how the 3006 module can enhance the safety and reliability of your industrial processes.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for TRICONEX’s official technical documentation. Always refer to the manufacturer’s guidelines for detailed installation, operation, and safety instructions.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: