Description

TRICONEX 3000470-510: High-Reliability Terminal Panel Module for Safety-Critical Industrial Systems

Product Overview

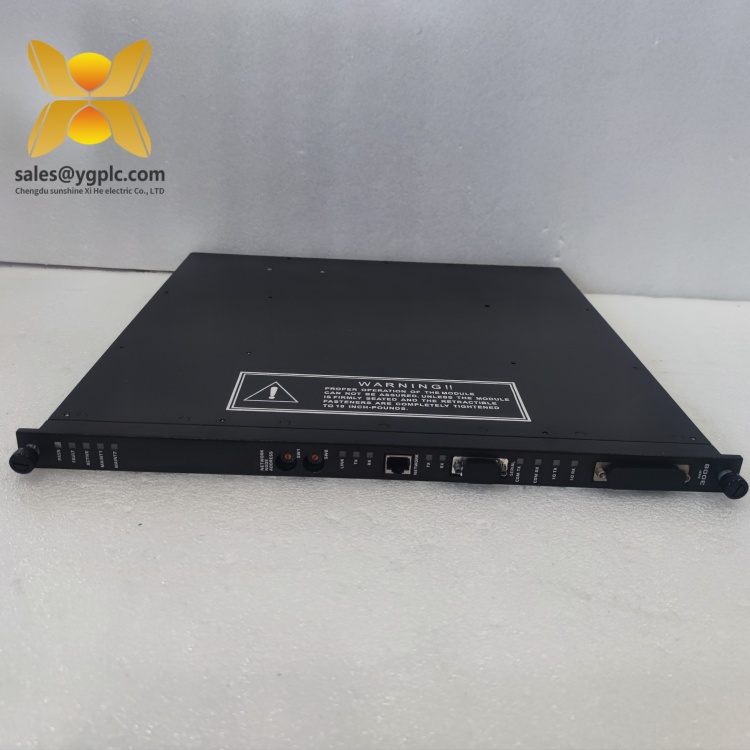

The TRICONEX 3000470-510 is a terminal panel module engineered for mission-critical industrial automation and safety instrumented systems (SIS). Designed to interface between field devices and TRICONEX’s Trident or Tricon controllers, this module provides a robust connection point for analog and digital signals while ensuring electrical isolation and diagnostic integrity. As part of TRICONEX’s extensive portfolio of I/O solutions, the 3000470-510 supports seamless integration with triple modular redundancy (TMR) architectures, adhering to the highest safety standards for hazardous environments.

The TRICONEX 3000470-510 excels in applications requiring precise signal conditioning and protection. With compatibility for 0-5V/0-10V analog inputs and discrete digital signals, it serves as a foundational component in process monitoring, emergency shutdown systems (ESD), and turbomachinery control. Its hot-swap capability and modular design enable maintenance without system downtime, while built-in diagnostics continuously monitor for faults like open circuits or voltage irregularities. Whether deployed in oil refineries, chemical plants, or power generation facilities, the 3000470-510 delivers unparalleled reliability, aligning with TRICONEX’s legacy of over 40 years in safety-critical automation.

Technical Specifications

| Parameter | Value |

|---|---|

| Product model | TRICONEX 3000470-510 |

| Manufacturer | TRICONEX |

| Product type | Terminal panel module |

| Physical dimensions | 190 mm (length) × 120 mm (width) × 65 mm (height) |

| Weight | 0.8 kg |

| Electrical specifications | 24 V DC operating voltage; 0.2 A maximum current consumption |

| Input/output channels | 16 isolated channels (8 analog, 8 digital) |

| Voltage range | Analog: 0-5V/0-10V DC; Digital: 24 V DC ±10% |

| Communication protocol | Supports TRICONEX proprietary protocol, Modbus RTU |

| Working environment | Operating temperature: -20°C to 60°C; Relative humidity: 10%–90% (non-condensing) |

| Installation requirements | DIN rail mounting, compatible with Trident system enclosures |

| Certifications | SIL 2 compliant (IEC 61508); ATEX/IECEx for hazardous areas (Zone 1/2) |

3000470-510

Related Products

- TRICONEX 7400165-380: A terminal panel module with similar form factor but optimized for high-current applications. While the 3000470-510 focuses on analog/digital signal conditioning, the 7400165-380 supports heavy-duty actuators and valves .

- TRICONEX 3700A: An isolated analog input module that pairs with the 3000470-510 to expand monitoring capabilities. The 3700A processes thermocouple and RTD signals, complementing the 3000470-510’s voltage-based inputs .

- TRICONEX 4329G: A network communication module that interfaces with the 3000470-510 to enable data exchange with higher-level systems like DCS or SCADA. It converts raw I/O data into standardized protocols for centralized control .

- TRICONEX 3603T: A digital output module offering fail-safe relay outputs. While the 3000470-510 handles input conditioning, the 3603T provides isolated switching for critical actuators in hazardous environments .

- TRICONEX 4210: The central processor module of TRICONEX SIS, which executes safety logic based on data received from the 3000470-510. The two modules are interdependent for system functionality .

Main Features and Advantages

Dual-Function Signal Conditioning

The TRICONEX 3000470-510 integrates both analog and digital signal processing in a single enclosure, reducing panel space and cabling complexity. Its analog channels support 0-5V/0-10V inputs, while digital channels handle 24 V DC signals, making it suitable for hybrid process monitoring applications .

Electrical Isolation and Noise Immunity

Advanced galvanic isolation separates field-side signals from the control system, eliminating ground loops and electromagnetic interference (EMI). This design ensures signal integrity even in electrically noisy environments, such as offshore platforms or chemical reactors .

SIL 2 Compliance and Fault Detection

Certified to SIL 2 under IEC 61508, the module meets safety requirements for moderate-risk applications. Built-in diagnostics monitor for faults like open circuits, short circuits, or overvoltage, triggering alarms and isolating affected channels to prevent cascading failures .

Hot-Swap Capability and Easy Maintenance

The 3000470-510 supports online replacement without system shutdown, minimizing downtime during repairs. Its modular design and intuitive LED indicators simplify troubleshooting, while firmware updates can be applied remotely via TRICONEX’s TriStation software .

3000470-510

Rugged Construction for Harsh Environments

Housed in a durable ATEX/IECEx-certified enclosure, the 3000470-510 withstands extreme temperatures (-20°C to 60°C), vibrations, and humidity. This makes it ideal for deployment in explosive atmospheres, such as oil refineries and gas processing plants .

Installation and Maintenance

Pre-installation Preparations

Before installing the TRICONEX 3000470-510, verify that the target Trident system is powered off and that the firmware version supports the module’s communication protocols. Inspect the module for physical damage, such as bent pins or cracked casings, and ensure the DIN rail is properly grounded. Confirm the 24 V DC power supply meets the module’s electrical specifications and that wiring connections comply with ATEX/IECEx standards for hazardous environments .

Maintenance Suggestions

Regular maintenance is critical to sustaining the 3000470-510’s performance. Conduct quarterly visual inspections to check for loose terminals, dust accumulation, or corrosion. Clean the module with compressed air and use insulation testers to verify wiring integrity. Update firmware annually to address security patches and performance optimizations, using TRICONEX’s TriStation software for seamless integration. In case of communication failures, check cable connections and power supply stability first; if issues persist, consult TRICONEX’s diagnostic guides or contact technical support .

Application Fields

The TRICONEX 3000470-510 is widely deployed in industries where safety and reliability are non-negotiable:

- Oil and Gas: Monitors pressure switches, flow sensors, and emergency shutdown buttons in upstream drilling rigs and midstream pipelines. Its SIL 2 certification ensures compliance with API RP 14C for blowout preventer (BOP) control systems .

- Chemical Processing: Integrates with fire and gas detection systems to trigger deluge valves or venting systems during leaks. It also supports batch reactor monitoring by conditioning analog signals from temperature and pressure transmitters .

- Power Generation: Supports turbine control systems by interfacing with vibration sensors and temperature switches, enabling predictive maintenance and preventing catastrophic equipment failures. In nuclear plants, it ensures compliance with NRC regulations for safety-critical instrumentation .

- Pharmaceuticals: Maintains sterile environments in cleanrooms by monitoring HVAC dampers and sterilization equipment, adhering to Good Manufacturing Practices (GMP) .

In each scenario, the 3000470-510’s dual-function design and diagnostic capabilities provide a fail-safe layer of protection, aligning with global safety standards and minimizing operational risks.

3000470-510

Product Guarantee

Our company offers a one-year quality warranty for the TRICONEX 3000470-510, covering hardware malfunctions unrelated to improper use. During the warranty period, defective modules will be replaced at no cost. For urgent or discontinued models, our global supply chain network ensures rapid procurement of scarce parts, minimizing downtime. Technical support is available 24/7 to assist with installation, troubleshooting, and firmware updates, ensuring seamless integration and long-term performance. We stand behind the 3000470-510’s ability to maintain industrial system continuity, reflecting our 17-year commitment to delivering reliable automation solutions .

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: