Description

Product Overview

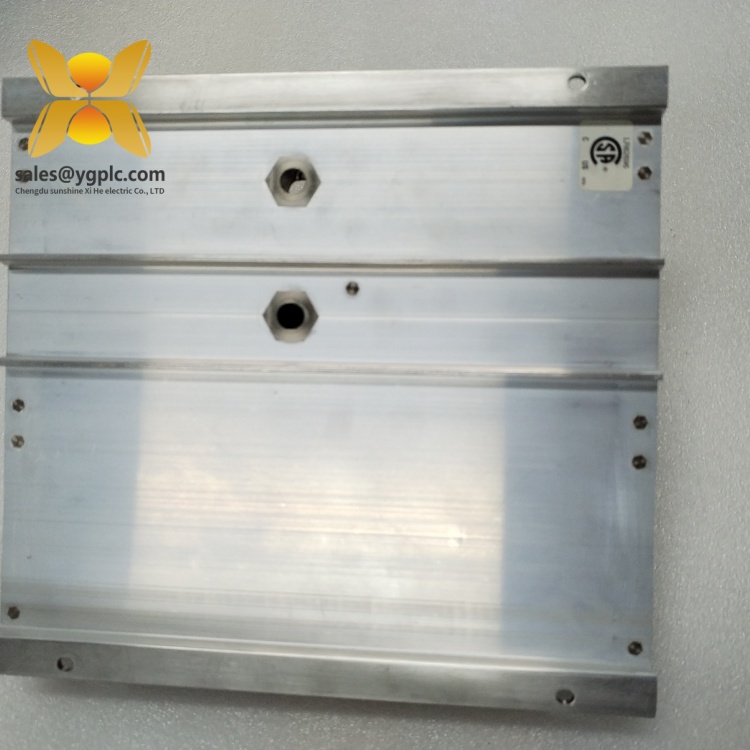

The TRICONEX 2211 is a high-performance analog input module designed for critical industrial automation and safety systems. Engineered to meet the demands of process control in hazardous environments, the TRICONEX 2211 excels in converting analog signals from field sensors (e.g., pressure, temperature, flow) into digital data for processing by TRICONEX safety controllers. As part of TRICONEX’s fault-tolerant architecture, this module ensures reliable signal acquisition even in high-risk applications, where inaccuracies could lead to catastrophic consequences.

With 32 differential input channels, the TRICONEX 2211 supports voltage ranges of 0–5V DC or -5–+5V DC, making it versatile for diverse sensor types. Its 12/14-bit programmable resolution and 0.15% FSR accuracy enable precise measurement of analog signals, while the 10 ms update rate ensures real-time monitoring of dynamic processes. The module’s robust design includes 85 dB common-mode rejection and 150V DC/115V AC overvoltage protection, safeguarding against electrical noise and transient spikes common in industrial settings. Whether integrated into a new Safety Instrumented System (SIS) or retrofitted into an existing infrastructure, the TRICONEX 2211 delivers consistent performance, reinforcing TRICONEX’s reputation for excellence in safety-critical applications.

Technical Specifications

| Product model | TRICONEX 2211 |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Analog input module |

| Physical dimensions | 165 mm (length) x 102 mm (width) x 32 mm (height) |

| Weight | 1.36 kg |

| Place of origin | United States |

| Input type | 32 differential channels |

| Voltage range | 0–5V DC or -5–+5V DC |

| Resolution | 12/14-bit programmable |

| Update rate | 10 ms |

| Accuracy | ±0.15% FSR (0–60°C) |

| Common-mode rejection | -85 dB (DC–100 Hz) |

| Overvoltage protection | 150V DC/115V AC continuous |

| Power supply | 24V DC ±10% |

| Operating temperature | -20°C to 60°C |

| Humidity tolerance | 5–95% non-condensing |

TRICONEX 2211

Related products

- TRICONEX 3211: A 16-channel analog input module with higher channel density, suitable for applications requiring fewer inputs but space-constrained setups.

- TRICONEX 3703E: An isolated analog input module with enhanced noise immunity, ideal for environments with severe electromagnetic interference.

- TRICONEX 4351B: A digital input module that complements the TRICONEX 2211 by providing discrete signal acquisition for integrated safety systems.

- TRICONEX 2651: The primary processor module in TRICONEX SIS, which processes data from the TRICONEX 2211 to execute safety logic.

- TRICONEX 3700A: A rack assembly designed to house the TRICONEX 2211 and other modules, ensuring mechanical stability and backplane connectivity.

- TRICONEX 4416: A communication module that enables the TRICONEX 2211 to transmit data to remote monitoring systems via high-speed protocols.

Main features and advantages

High-precision signal conditioning: The TRICONEX 2211’s 12/14-bit resolution and 0.15% FSR accuracy ensure precise measurement of analog signals, critical for maintaining process integrity in industries like oil refining and chemical production. Its differential input design minimizes errors caused by ground loops, making it suitable for long-distance sensor connections.

Fast update rate: With a 10 ms update rate, the TRICONEX 2211 delivers real-time data to the safety controller, enabling rapid response to process deviations. This is particularly vital in applications such as turbine control, where delays could lead to equipment damage.

Robust electromagnetic immunity: The module’s 85 dB common-mode rejection and dual-layer shielding (foil and braided) effectively block EMI/RFI, ensuring signal integrity in noisy environments like power plants or offshore rigs. Its 150V DC/115V AC overvoltage protection further safeguards against transient spikes, extending module lifespan.

Flexible configuration: The TRICONEX 2211 supports both 0–5V DC and -5–+5V DC input ranges, accommodating a wide array of analog sensors. Its programmability allows engineers to adjust resolution and scaling parameters via TRICONEX’s Tristation 1131 software, tailoring the module to specific application needs.

Reliable safety certification: While the TRICONEX 2211 itself is not SIL-certified, it is part of TRICONEX’s SIL 3–capable SIS architecture, ensuring compliance with IEC 61508 standards when integrated into a complete system.

TRICONEX 2211

Installation and maintenance

Pre-installation preparations: Before installing the TRICONEX 2211, verify that the TRICONEX rack (e.g., TRICONEX 3700A) is properly grounded and mounted on a stable surface. Check the 24V DC power supply meets voltage requirements and inspect the module for physical damage (e.g., bent pins, cracked casing). Confirm compatibility with the system’s firmware version to avoid communication issues.

Installation steps: Align the TRICONEX 2211 with the designated slot in the rack, ensuring the backplane connectors engage fully. Secure the module with front-panel screws to prevent vibration-induced disconnections. Connect shielded twisted-pair cables from field sensors to the terminal block, following the wiring diagram in the user manual. Route cables away from high-voltage lines to minimize interference.

Maintenance suggestions: Conduct quarterly visual inspections to check for loose connections or corrosion. Clean terminal blocks with a dry cloth to remove dust that could cause short circuits. Annually test input channels using a precision voltage source to ensure accuracy; recalibrate or replace the module if deviations exceed ±0.15% FSR. Monitor the module’s status LEDs for faults (e.g., red indicators), and address issues promptly using TRICONEX’s diagnostic tools.

Application fields

The TRICONEX 2211 is widely deployed in industries where precise analog signal acquisition is critical:

- Oil and gas: In offshore platforms, the module monitors pressure and temperature sensors in wellheads and pipelines, providing data for emergency shutdown systems (ESDs) to prevent hydrocarbon leaks.

- Chemical processing: It measures pH levels, flow rates, and reactor temperatures in chemical plants, enabling closed-loop control to maintain safe process conditions and comply with environmental regulations.

- Power generation: The TRICONEX 2211 supports steam turbine control by acquiring analog signals from vibration sensors and thermocouples, ensuring optimal performance and early detection of mechanical issues.

- Pharmaceutical manufacturing: It monitors sterilization processes and cleanroom environments by measuring humidity and pressure, ensuring compliance with FDA and EU GMP standards.

TRICONEX 2211

Product guarantee

Our company offers a one-year quality warranty for the TRICONEX 2211, covering hardware malfunctions unrelated to misuse or improper installation. During the warranty period, defective modules will be replaced promptly to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce parts like the TRICONEX 2211, supported by 17 years of expertise in industrial control solutions. Our technical team provides 24/7 assistance for installation guidance, troubleshooting, and firmware updates, ensuring seamless integration and long-term reliability.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: