Description

Product Overview

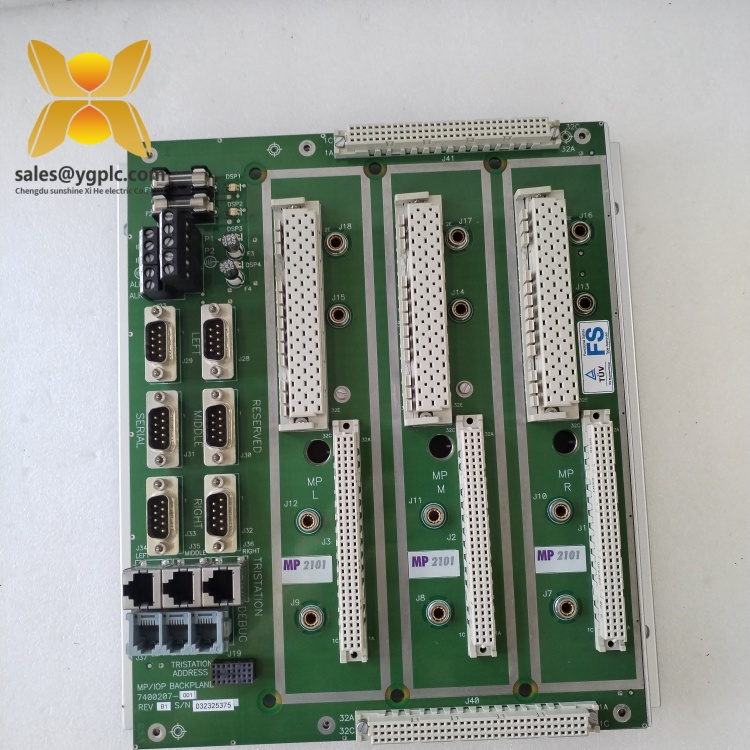

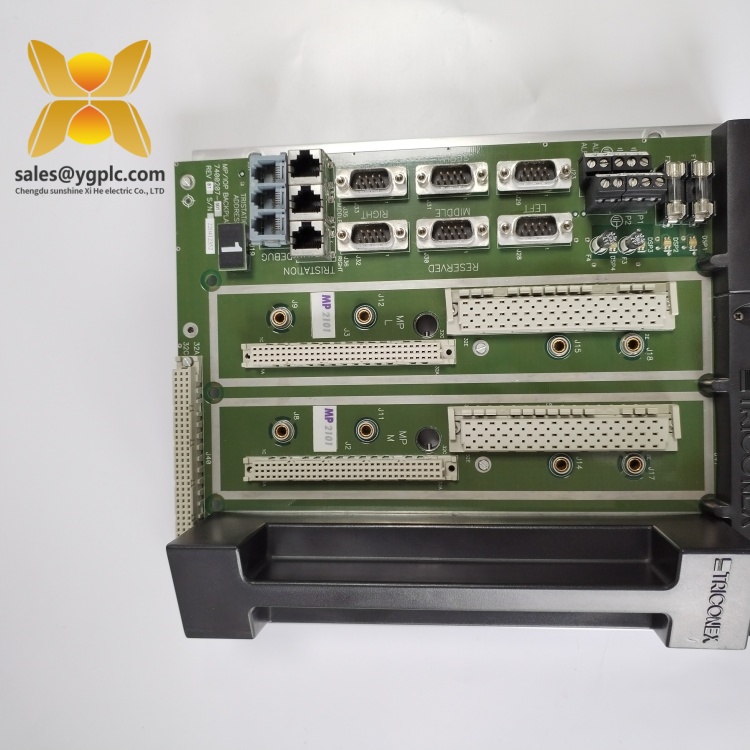

The TRICONEX 2000418 is a crucial component in industrial automation systems, specifically an I/O CPU panel controller. As a product of TRICONEX, a well – known brand in the field of industrial control, TRICONEX 2000418 plays a significant role in safety – critical applications. It is part of the redundant fault – tolerant control system, which is based on the triple module redundancy (TMR) structure, ensuring high – reliability and stability.

The core function of TRICONEX 2000418 is to manage and process input/output signals, enabling seamless communication between different parts of the automation system. It can accurately receive various input signals, perform necessary logic operations, and then output control signals to drive relevant devices. In the automation system, it is positioned as a key control module, which is essential for the stable operation of the entire system. Its value lies in its high – compatibility and scalability, which can adapt to different industrial scenarios. It is not limited to a specific industrial protocol, making it easy to integrate with other non – Bosch solutions, thus providing strong support for the construction of complex industrial automation systems.

Technical Specifications

| Parameter Name | Parameter Values |

|---|---|

| Manufacturer | TRICONEX |

| Product Type | Control module |

| Voltage Range | 12 – 455 VDC |

| Output Range | 120 mA |

| Over – range Protection (VDC) | 21 |

| Input Range | 33 mA |

| Working Temperature | Suitable for a certain working temperature environment (specific value not clearly stated, generally industrial – grade temperature range) |

| System Memory | 500.020 MB |

| Interface | 5 interfaces (specific type not clearly stated, may be various common industrial interfaces) |

| Color Code | Black and blue |

| Weight | 14.55 kg |

| Dimension | 425 mm×885 mm×748 mm |

2000418

Related products

- TRICONEX 2000419: It may be a similar model in the same series, possibly with some upgraded functions or different parameter settings, and is also used for control and communication in industrial automation systems.

- TRICONEX 2000417: This model is likely to have a similar structure and application scenario as TRICONEX 2000418, and can be used as an alternative or complementary product in some cases.

- TRICONEX 3000 series models: Such as TRICONEX 3001, TRICONEX 3002, etc. These are higher – end products in the TRICONEX series, with more powerful processing capabilities and more comprehensive functions, and can be used in larger – scale and more complex industrial control systems.

- TRICONEX 1000 series models: Like TRICONEX 1005, TRICONEX 1008, etc. They are relatively basic models, which may have simpler functions than TRICONEX 2000418, and are suitable for some small – scale or less complex control scenarios.

- TRICONEX 4000 series models: For example, TRICONEX 4003, which may be designed for specific industrial applications, with unique functions or interface characteristics, and can be used in conjunction with TRICONEX 2000418 in some special occasions.

Main features and advantages

The TRICONEX 2000418 has many outstanding features and advantages. Firstly, its redundant fault – tolerant design based on TMR structure ensures high – reliability. Even if a single module fails, the entire system can still operate normally, reducing the risk of system downtime and ensuring the continuous operation of industrial production. Secondly, its wide voltage range of 12 – 455 VDC makes it adaptable to different power supply environments, enhancing the stability of the system in different power conditions.

In addition, the TRICONEX 2000418 has good compatibility. It is not overly dependent on a certain industrial protocol, which can be easily integrated with various non – Bosch devices, providing users with more choices in system configuration. The large – capacity system memory of 500.020 MB allows it to store a large amount of data and program instructions, enabling complex logic operations and data processing. Moreover, its compact and reasonable physical dimensions of 425 mm×885 mm×748 mm and a weight of 14.55 kg make it easy to install and install in various industrial sites, which can save space and facilitate on – site layout.

2000418

Installation and maintenance

Pre – installation preparations: Before installing TRICONEX 2000418, it is necessary to ensure that the installation site meets the environmental requirements, such as a suitable temperature and humidity environment, and is free from strong electromagnetic interference. Check whether the power supply meets the voltage range requirements of 12 – 455 VDC to avoid damage to the module caused by improper power supply. At the same time, prepare the necessary installation tools, and ensure that the installation position is firm and can bear the weight of the module.

Maintenance suggestions: Regularly check the operating status of TRICONEX 2000418, including whether the indicator lights are normal and whether there are abnormal noises or heat generation. Clean the surface of the module regularly to prevent dust from affecting its heat dissipation and normal operation. Check the connection of each interface regularly to ensure that there is no looseness or poor contact. If a fault is found, record the fault phenomenon in time, and contact professional maintenance personnel for maintenance. According to the actual use situation, periodically perform software upgrades and parameter adjustments to ensure that the module can always maintain the best operating state.

Maintenance suggestions: Regularly check the operating status of TRICONEX 2000418, including whether the indicator lights are normal and whether there are abnormal noises or heat generation. Clean the surface of the module regularly to prevent dust from affecting its heat dissipation and normal operation. Check the connection of each interface regularly to ensure that there is no looseness or poor contact. If a fault is found, record the fault phenomenon in time, and contact professional maintenance personnel for maintenance. According to the actual use situation, periodically perform software upgrades and parameter adjustments to ensure that the module can always maintain the best operating state.

Application fields

The TRICONEX 2000418 is widely used in the petrochemical industry. In petrochemical production, there are many high – risk processes, and the safety and stability of the system are of great significance. TRICONEX 2000418 can be used for the control and monitoring of various production devices, such as reactors, distillation columns, etc., to ensure the safe and stable operation of the production process. It can also be applied to other industrial fields with high – safety requirements, such as the chemical industry, power generation, and nuclear power. In the chemical industry, it is used to control chemical reaction processes and material transportation; in the power generation industry, it is responsible for the control of power generation equipment and the monitoring of the power grid; in the nuclear power industry, it plays a key role in the safety control system, ensuring the safe operation of nuclear power plants. In general, wherever there is a need for high – reliability, high – safety control and communication in industrial automation, TRICONEX 2000418 can play an important role.

2000418

Product guarantee

Our company offers a one – year quality warranty service for the TRICONEX 2000418, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. Relying on our global supply chain network, for discontinued models or urgent demands, we can quickly respond to customers’ procurement needs for scarce spare parts. We are committed to ensuring the continuous and stable operation of industrial systems, providing customers with reliable product quality and perfect after – sales service, and making every effort to meet customers’ various needs in the process of using products.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: