Description

Rockwell TC-302-02-4M0 Temperature Controller Module

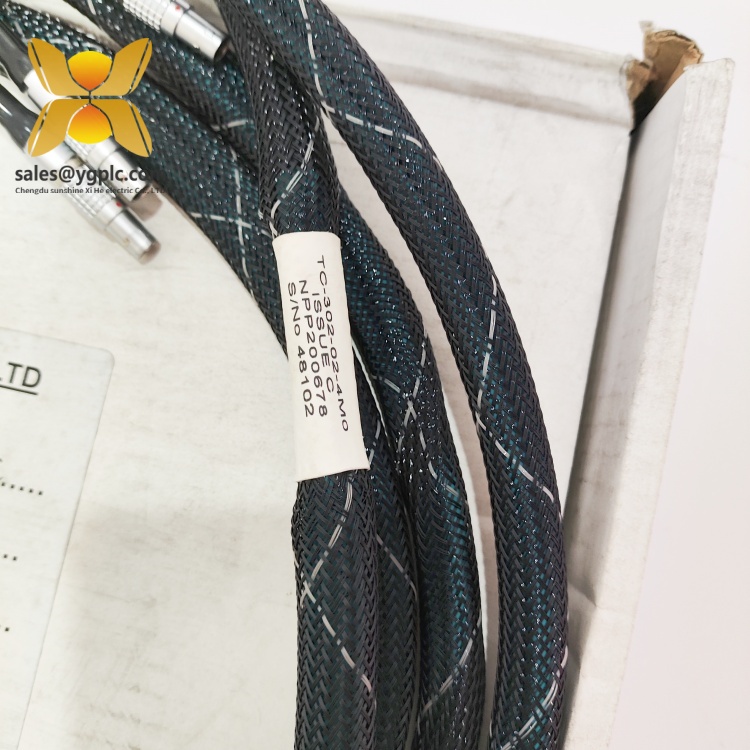

Product Overview:Rockwell TC-302-02-4M0

The Rockwell TC-302-02-4M0 is a high-precision Temperature Controller Module designed for industrial automation systems, specifically as part of Rockwell Automation’s Allen-Bradley ControlLogix platform. Engineered to manage complex temperature control applications, this module serves as a critical component in maintaining process stability across industries such as manufacturing, food & beverage, chemical processing, and energy production. The TC-302-02-4M0 integrates advanced PID control algorithms and multi-loop functionality, enabling precise regulation of temperature in furnaces, ovens, reactors, and heat exchangers. As a compact and rugged solution, it ensures reliable performance in harsh industrial environments while seamlessly integrating with Rockwell’s broader ecosystem of PLCs, HMIs, and SCADA systems.

Featuring four independent control loops, the Rockwell TC-302-02-4M0 supports a wide range of temperature sensors (e.g., RTDs, thermocouples) and output types (relay, analog, or digital), providing flexibility for diverse applications. Its modular design allows easy installation in ControlLogix racks, while built-in diagnostics and real-time data logging enhance troubleshooting efficiency. The module’s compatibility with Rockwell’s Studio 5000 software enables intuitive configuration, remote monitoring, and predictive maintenance, reducing downtime and optimizing operational efficiency. Whether deployed in standalone setups or large-scale distributed control systems, the TC-302-02-4M0 delivers consistent accuracy and reliability, making it an essential tool for industries where temperature control is non-negotiable.

As part of Rockwell’s commitment to industrial innovation, the TC-302-02-4M0 embodies the brand’s legacy of robust, future-proof solutions. Its dual-channel communication (EtherNet/IP and ControlNet) ensures seamless data exchange with higher-level systems, while advanced security features protect against unauthorized access. By combining precision control with rugged durability, this module empowers operators to achieve tight temperature tolerances, comply with regulatory standards, and minimize energy consumption, ultimately driving productivity and sustainability in industrial processes.

Technical Specifications:Rockwell TC-302-02-4M0

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TC-302-02-4M0 |

| Manufacturer | Rockwell Automation |

| Product Type | Temperature Controller Module |

| Control Loops | 4 independent loops |

| Input Types | RTD (3-wire, 4-wire), thermocouple (J, K, T, E, R, S, B, N), analog voltage/current |

| Output Types | Relay (24 V DC/250 V AC), 4–20 mA analog, digital (EtherNet/IP) |

| Communication | EtherNet/IP, ControlNet, DeviceNet |

| Physical Dimensions | 171.45 mm (H) × 44.45 mm (W) × 127 mm (D) |

| Weight | 0.45 kg |

| Operating Temperature | 0°C to +60°C (with derating up to +70°C) |

| Mounting | Rack-mounted (ControlLogix 1756 series) |

| Power Supply | 24 V DC ±10% (from ControlLogix rack) |

| Certifications | CE, UL, CSA, ATEX (for hazardous environments) |

Rockwell TC-302-02-4M0

Key Features and Advantages:Rockwell TC-302-02-4M0

Multi-Loop Precision Control: The TC-302-02-4M0 supports four simultaneous control loops, each with independent PID parameters, enabling complex temperature profiling in multi-zone systems. Its advanced auto-tuning feature optimizes PID settings for dynamic processes, reducing overshoot and settling time.

Flexible I/O Configuration: With configurable input/output channels, the module adapts to various sensor types and actuator requirements, eliminating the need for external signal converters. This flexibility simplifies system design and reduces hardware costs.

Robust Industrial Design: Built with a rugged metal enclosure and conformal coating, the TC-302-02-4M0 withstands vibration, moisture, and electromagnetic interference, ensuring reliable operation in harsh environments like production floors and outdoor installations.

Seamless System Integration: As a native ControlLogix module, the TC-302-02-4M0 integrates effortlessly with Rockwell’s Studio 5000 software and other Allen-Bradley components (e.g., 1756 I/O modules, PanelView HMIs), creating a unified control ecosystem. Its support for open protocols like EtherNet/IP also enables integration with third-party systems.

Advanced Diagnostics and Security: Real-time diagnostics monitor loop health, sensor connectivity, and power status, with alarm notifications sent via email or SCADA. The module’s secure communication protocols (e.g., TLS/SSL) protect against cyber threats, ensuring compliance with industrial cybersecurity standards.

Energy Efficiency: The module’s precise control minimizes energy waste by maintaining optimal temperature setpoints, while its sleep mode during idle periods further reduces power consumption. This contributes to lower operational costs and environmental sustainability.

Rockwell TC-302-02-4M0

Application Areas:Rockwell TC-302-02-4M0

The Rockwell TC-302-02-4M0 is widely applied in industries requiring precise and reliable temperature control:

- Manufacturing: Controls oven temperatures in automotive paint lines, plastic extrusion processes, and metal heat treatment facilities, ensuring product quality and process consistency.

- Food & Beverage: Manages pasteurization tanks, cooking systems, and cold storage units, adhering to strict hygiene standards and regulatory requirements (e.g., FDA, HACCP).

- Chemical Processing: Regulates reactor temperatures in pharmaceutical synthesis, petrochemical refining, and polymer production, preventing thermal runaway and ensuring safety.

- Energy & Utilities: Optimizes boiler and turbine temperatures in power plants, enhancing energy conversion efficiency and reducing emissions.

- HVAC & Facilities Management: Controls heating systems in commercial buildings, data centers, and industrial warehouses, balancing comfort and energy efficiency.

Specific applications include:

- Batch Processing: Sequential temperature control for batch reactors, ensuring repeatable results in pharmaceutical and chemical manufacturing.

- Curing Processes: Maintains precise temperature profiles in composite material curing ovens, critical for aerospace and automotive industries.

- Environmental Testing: Controls chamber temperatures in product reliability testing, simulating extreme climates for electronics and industrial components.

Rockwell TC-302-02-4M0

Related Products:Rockwell TC-302-02-4M0

- TC-302-01-2M0: A 2-loop variant of the TC-302-02-4M0, suitable for smaller-scale applications or systems requiring fewer control channels.

- 1756-IT6I: Analog input module for ControlLogix, expanding the TC-302-02-4M0’s capability to handle additional temperature sensors or process variables.

- 1756-OF8: Analog output module for driving actuators (e.g., valves, heaters) in conjunction with the TC-302-02-4M0’s control signals.

- PanelView 800 HMI: Provides a user interface for configuring and monitoring the TC-302-02-4M0, enabling real-time temperature trend visualization.

- 1756-L82E Controller: High-performance PLC controller that coordinates with the TC-302-02-4M0 for complex automation sequences.

- TC-302-03-8M0: 8-loop expansion module, ideal for large-scale systems requiring multiple temperature zones.

- 1756-CNB/E ControlNet Bridge: Enhances communication flexibility for the TC-302-02-4M0 in legacy ControlNet networks.

- Rockwell Software AssetCentre: Manages firmware updates and configuration backups for the TC-302-02-4M0, ensuring system consistency.

Installation and Maintenance:Rockwell TC-302-02-4M0

Installation Preparation:

Before installing the Rockwell TC-302-02-4M0, ensure the ControlLogix rack is properly grounded and powered. Verify compatibility with existing sensors and actuators, using shielded cables for analog inputs to minimize noise. Mount the module in an empty slot within the rack, securing it with the provided screws. Use Studio 5000 to configure network settings, assign IP addresses, and define loop parameters (e.g., sensor type, control mode).

Before installing the Rockwell TC-302-02-4M0, ensure the ControlLogix rack is properly grounded and powered. Verify compatibility with existing sensors and actuators, using shielded cables for analog inputs to minimize noise. Mount the module in an empty slot within the rack, securing it with the provided screws. Use Studio 5000 to configure network settings, assign IP addresses, and define loop parameters (e.g., sensor type, control mode).

Maintenance Recommendations:

- Routine Checks: Perform monthly inspections to ensure secure wiring, clean ventilation slots, and monitor module health via Studio 5000. Replace faulty sensors or actuators promptly to maintain control accuracy.

- Calibration: Annually calibrate the module using Rockwell’s calibration tools or certified third-party equipment, documenting results for compliance.

- Firmware Updates: Periodically update firmware to access new features and security patches, following Rockwell’s guidelines to avoid configuration loss.

- Spare Parts Management: Store spare TC-302-02-4M0 modules in a dry, static-free environment at room temperature. Rotate inventory to ensure shelf-life viability for urgent replacements.

Rockwell TC-302-02-4M0

Product Warranty:Rockwell TC-302-02-4M0

Our company provides a 12-month quality warranty for the Rockwell TC-302-02-4M0, covering hardware defects under normal use. In case of performance issues, we offer prompt replacement services to minimize downtime. For discontinued models or urgent needs, our global supply chain network efficiently sources rare industrial control parts, ensuring quick turnaround. Our technical support team is available 24/7 to assist with installation, programming, and troubleshooting, delivering tailored solutions to keep your systems operating at peak performance.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

ROCKWELL TC-205-02-8M5 regulator

ROCKWELL SA3100-R030-AX-L6R T491498R0 I/O board

GE IS200TRLYH1BHH Power strip

GE 201CI-1 Power source

GE 531X305NTBAJG1 base

GE 531X305NTBANG1 exchange

TRICONEX AI2351 7400210-010 Connecting module

TRICONEX AO3482 driver

TRICONEX EPI3382 servo

TRICONEX 8120E Eddy current sensor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: