Description

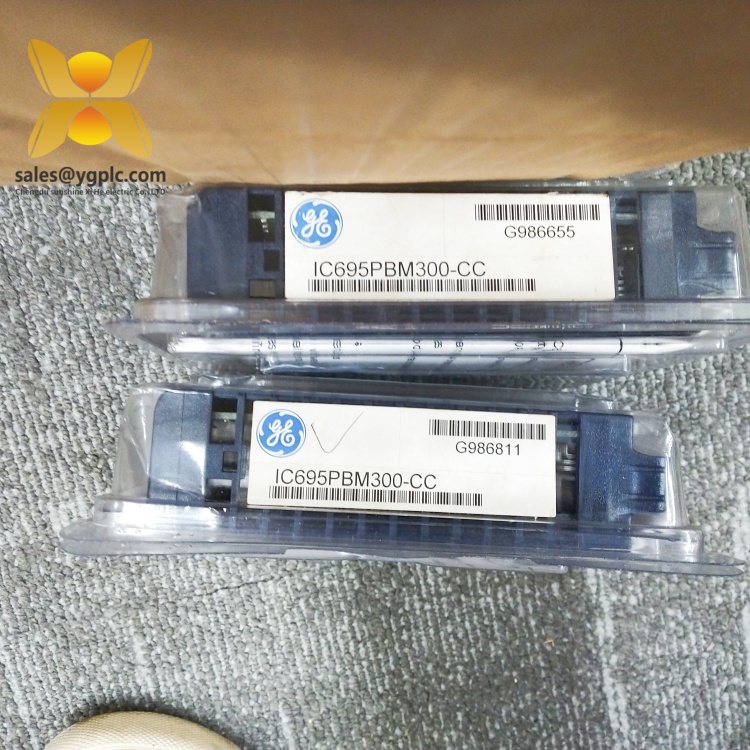

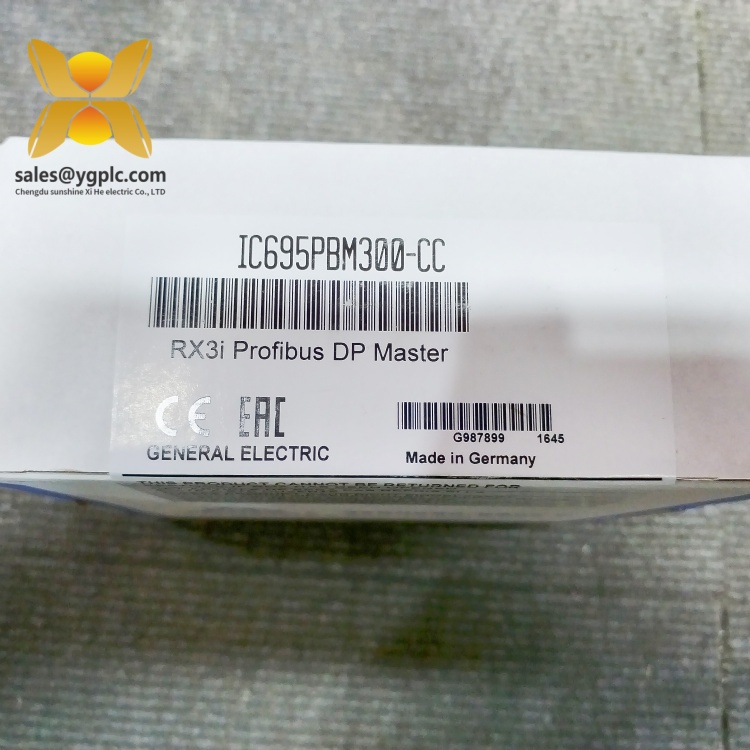

GE IC695PBM300 PACSystems RX3i Backplane Module

Product Overview

The GE IC695PBM300 is a high-performance backplane module designed for GE’s PACSystems RX3i programmable automation controllers, serving as the critical interconnect backbone for modular automation systems. As part of the IC695 Series, this backplane enables seamless communication and power distribution between RX3i modules—including controllers, I/O modules, and communication cards—ensuring reliable data flow in industrial environments.

Featuring a 10-slot configuration, the GE IC695PBM300 supports high-speed data transfer across connected modules via its proprietary bus architecture, which operates at 1 Gbps to minimize latency. This ensures real-time synchronization between components, critical for applications like turbine control or precision manufacturing. The backplane’s rugged metal chassis and conformal coating protect against dust, vibration, and electromagnetic interference (EMI), making it suitable for harsh settings such as factories with heavy machinery or offshore platforms.

In automation systems, the IC695PBM300 integrates seamlessly with the RX3i ecosystem, accommodating a mix of digital, analog, and specialty modules to meet diverse application needs. Its hot-swappable support allows modules to be replaced without powering down the system, reducing downtime in 24/7 operations. By combining robust construction, high-speed connectivity, and flexible scalability, the GE IC695PBM300 forms the foundation of reliable, high-performance automation systems, enhancing operational efficiency across industries.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IC695PBM300 |

| Manufacturer | GE |

| Product Type | Backplane Module (PACSystems RX3i) |

| Series | IC695 (PACSystems RX3i) |

| Slot Configuration | 10 slots (compatible with RX3i modules) |

| Data Transfer Rate | 1 Gbps (proprietary backplane bus) |

| Power Distribution | Distributes 5 V DC and 24 V DC to connected modules (from external power supply) |

| Physical Dimensions | 355.6 mm (W) × 127 mm (H) × 101.6 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95% (non-condensing) |

| Certifications | CE, UL 508, ATEX Zone 2, IEC 61131-2 |

| Mounting | Panel mount or DIN rail (with optional adapter) |

Main Features and Advantages

High-speed data backbone:

The IC695PBM300’s 1 Gbps backplane bus ensures rapid data transfer between connected modules, minimizing latency in time-critical applications. For example, in automotive assembly lines, this speed enables the RX3i controller to receive sensor data from I/O modules and send actuation signals to robotic arms in microseconds, ensuring precise synchronization.

Flexible 10-slot configuration:

With 10 slots, the backplane accommodates a mix of RX3i modules—including IC695CPU310 controllers, IC695ALG508 analog input modules, and IC695CMM002VC communication cards—supporting scalable system designs. This flexibility allows engineers to customize configurations for specific needs, from small-scale machines to large industrial processes.

Rugged environmental resilience:

The IC695PBM300’s metal chassis and conformal coating withstand extreme temperatures (-25°C to +70°C), vibration, and EMI, ensuring reliability in harsh environments. It thrives in settings like steel mills, where dust and electrical noise are prevalent, or desert power plants with wide temperature swings.

Seamless power distribution:

The backplane distributes 5 V DC (for logic) and 24 V DC (for field devices) to connected modules, eliminating the need for separate power harnesses. This integrated design reduces wiring complexity, lowers installation time, and minimizes points of failure.

Hot-swappable module support:

Compatible with hot-swappable RX3i modules, the IC695PBM300 allows replacement of I/O or communication cards without powering down the system. This feature is critical for 24/7 operations—such as chemical batch processing—where unplanned downtime can incur significant losses.

Enhanced system diagnostics:

The backplane works with the RX3i controller to monitor module presence, power status, and bus health, alerting operators to faults like a loose module or a failing power supply. This proactive monitoring reduces mean time to repair (MTTR), ensuring continuous operation.

Broad module compatibility:

Designed exclusively for the PACSystems RX3i platform, the IC695PBM300 supports all IC695 Series modules, ensuring long-term compatibility with future upgrades. This protects investment in automation infrastructure, as new modules can be integrated without replacing the backplane.

Application Areas

The GE IC695PBM300 is indispensable in industries requiring modular, reliable automation systems:

- Manufacturing:

Serves as the backbone for assembly line control systems, connecting robotic controllers, vision sensors, and conveyor I/O modules. Its high-speed bus ensures synchronized operation of multiple machines, improving production throughput. - Energy Sector:

Integrates with turbine control modules, temperature sensors, and grid synchronization devices in power plants. The backplane’s rugged design withstands the vibration and EMI from generators, ensuring stable data flow for efficient energy production. - Chemical Processing:

Connects reactor I/O modules, pressure transducers, and emergency shutdown (ESD) cards in batch processing facilities. Its hot-swappable support allows maintenance during scheduled breaks, avoiding costly interruptions to chemical reactions. - Water and Wastewater:

Links pump controllers, flow meters, and treatment process I/O modules in filtration plants. The backplane’s corrosion-resistant coating ensures reliability in humid, chemically exposed environments.

Specific applications include coordinating robotic welders in automotive plants, synchronizing turbine sensors in combined-cycle power plants, and managing valve actuators in water treatment facilities.

Related Products

- GE IC695PBM200(PACSystems RX3i Backplane Module):

A 5-slot variant of the IC695PBM300, ideal for smaller systems like standalone packaging machines. Shares the same high-speed bus but with reduced slot capacity. - GE IC695CPU310(PACSystems RX3i Controller):

The central processing unit that slots into the IC695PBM300, leveraging the backplane to communicate with I/O and communication modules. - GE IC695PSD140(PACSystems RX3i Power Supply):

Provides regulated 5 V DC and 24 V DC power to the IC695PBM300, which distributes it to connected modules. Ensures stable power in fluctuating mains environments. - GE IC695ALG508(PACSystems RX3i Analog Input Module):

Plugs into the IC695PBM300 to convert sensor signals (e.g., pressure, temperature) into digital data, relying on the backplane for power and communication. - GE IC695CMM002VC(PACSystems RX3i Communication Module):

Uses the IC695PBM300’s bus to exchange data between the RX3i system and external networks (Ethernet/IP, Profibus), enabling remote monitoring. - GE IC695MDL645(PACSystems RX3i Digital Input Module):

Connects to the backplane to transmit limit switch and sensor status data to the RX3i controller, supporting high-speed input processing. - GE IC695AOG500(PACSystems RX3i Analog Output Module):

Receives control signals via the IC695PBM300’s bus, converting them into 4–20 mA outputs to regulate valves or variable-speed drives.

Installation and Maintenance

Pre-installation preparations:

Ensure the mounting surface (panel or DIN rail) is flat, grounded, and within the -25°C to +70°C operating range. Verify compatibility with RX3i modules using GE’s module compatibility guide. Mount the IC695PBM300 using the provided hardware, ensuring a secure fit to minimize vibration. Connect the external power supply (e.g., IC695PSD140) to the backplane’s power input, checking polarity to avoid damage.

Maintenance suggestions:

Perform quarterly visual inspections to ensure modules are fully seated in the backplane slots; reseat any loose modules to maintain bus connectivity. Clean dust from the backplane’s ventilation slots biannually using compressed air, especially in dusty environments like cement plants. Monitor power distribution via the RX3i controller’s diagnostics to detect anomalies, such as voltage drops that could indicate a failing power supply. Store spare IC695PBM300 units in anti-static packaging at 10–30°C with <60% humidity, testing them annually to confirm bus functionality.

Product Guarantee

Our company offers a one-year quality warranty service for the IC695PBM300, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

As a leading enterprise in the industrial control industry, established in 2007, we have 17 years of experience. We are an import and export trade distribution company, mainly selling major brands of industrial control parts, with many unpopular discontinued models and a large stock. Our supply channel advantages ensure a large number of in-stock items, meeting customers’ urgent needs for spare parts. We distribute PLC modules, DCS cards, ESD system cards, and more, with a focus on reliable service and timely delivery.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: