Description

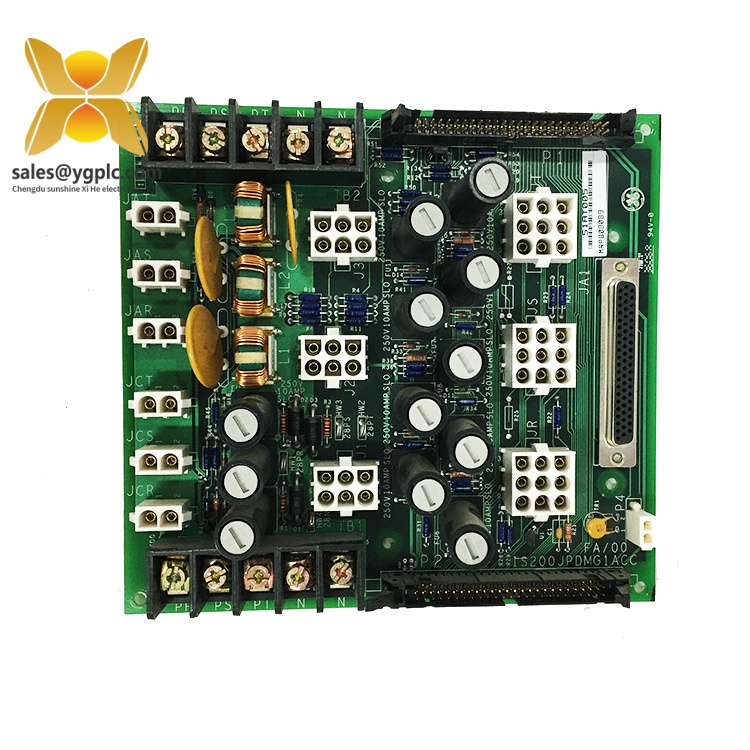

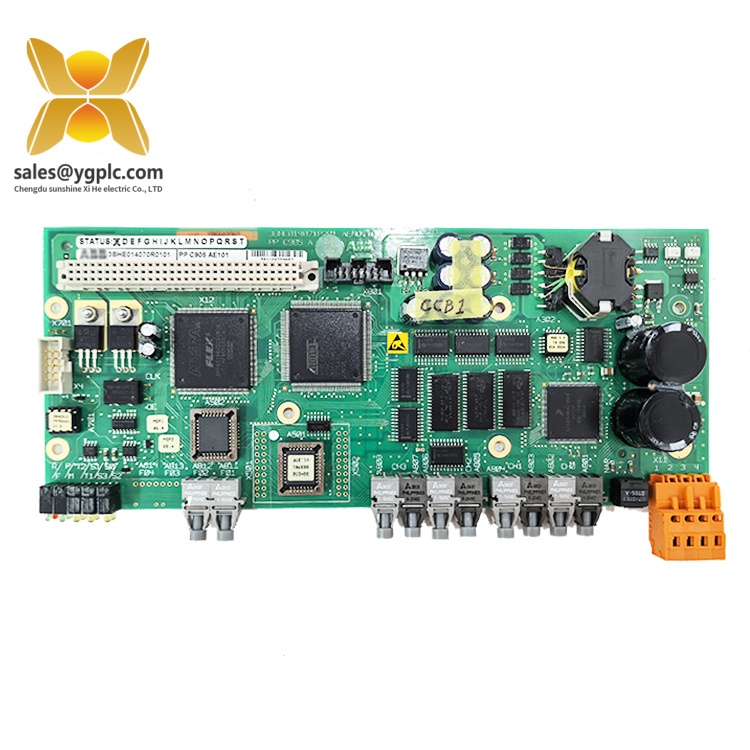

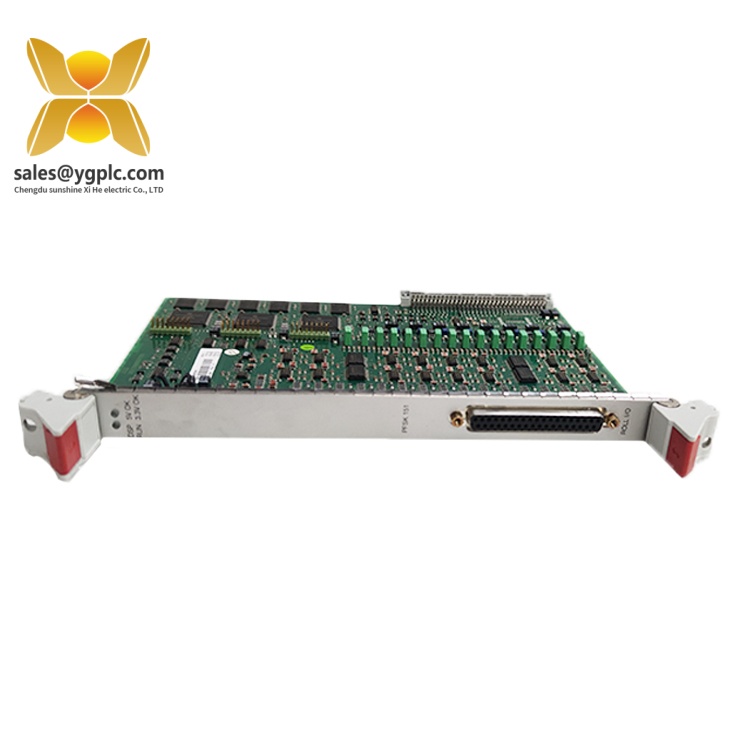

GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C VMEbus Single Board Computer

Product Overview: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

The GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C is a high-performance industrial automation component designed for GE’s Mark VI Speedtronic™ turbine control systems, a flagship platform for managing steam and gas turbines in critical power generation and industrial processes. As a core element of the VMIVME series, this VMEbus single board computer (SBC) serves as a real-time controller and communication hub, enabling seamless coordination of turbine operations, safety interlocks, and data exchange across complex automation architectures. Engineered for mission-critical environments, the IS215UCVEH2AB integrates advanced hardware features, rugged durability, and modular flexibility to ensure uninterrupted system performance.

Featuring an Intel Celeron 300 MHz processor, 32 MB DRAM, and 16 MB flash memory, the IS215UCVEH2AB executes control algorithms and diagnostic routines with precision. Its QNX real-time operating system supports deterministic task scheduling, ideal for applications requiring microsecond-level response times. The module’s dual Ethernet ports (10/100 Mbps) and two RS-232 serial interfaces enable connectivity to I/O modules, supervisory networks, and legacy systems, while the hot-swappable design allows maintenance without system shutdown—a critical feature for 24/7 power generation facilities. The -40°C to +70°C operating range and rugged metal enclosure ensure reliability in harsh environments, from offshore oil platforms to high-temperature power plant control rooms.

Within automation systems, the IS215UCVEH2AB acts as a central processing unit for GE’s Mark VI architecture, translating sensor inputs into actionable control signals and enforcing safety protocols such as emergency shutdowns and fault isolation. Its compatibility with VMEbus backplanes and compliance with IEEE 1131-2 and IEC 61131-3 standards solidify its role in large-scale turbine installations, where precision and redundancy are non-negotiable.

Technical Specifications: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS215UCVEH2AB VMIVME-7614-132 350-007614-132C |

| Manufacturer | GE |

| Product Type | VMEbus Single Board Computer (SBC) |

| Series | Mark VI Speedtronic™, VMIVME Series |

| Processor | Intel Celeron 300 MHz |

| Memory | 32 MB DRAM, 16 MB Flash |

| Operating System | QNX Real-Time OS |

| Communication Interfaces | 2 x Ethernet (10/100 Mbps), 2 x RS-232 |

| Power Supply | +5 VDC, 6A typical / 8A maximum |

| Physical Dimensions | 18.0 in (H) × 12.0 in (W) × 12.0 in (D) |

| Weight | 4.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (VMEbus compatible) |

| Compliance | IEEE 1131-2, IEC 61131-3 |

| Country of Origin | United States |

Main Features and Advantages: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

Real-Time Control and Communication: The IS215UCVEH2AB leverages its Intel Celeron processor and dual Ethernet ports to manage real-time data exchange between the turbine control system and external devices, ensuring precise synchronization of excitation currents, speed regulation, and load distribution. Its support for industrial protocols like Modbus TCP/IP (via Ethernet) and RS-232 minimizes latency and enhances interoperability with SCADA systems and remote monitoring platforms.

Redundant and Rugged Design: With dual redundant power inputs and a robust metal enclosure, the module withstands voltage fluctuations, vibration, and extreme temperatures. The hot-swappable capability allows technicians to replace or upgrade components without disrupting operations—a critical feature for uninterrupted power generation. Built-in LED indicators (Active, OK, Ethernet, Flash) provide instant visual feedback on system health, while self-diagnostic routines monitor hardware integrity, communication errors, and firmware status.

Modular Flexibility: Designed for GE’s modular Mark VI architecture, the IS215UCVEH2AB integrates seamlessly with other VMIVME series modules (e.g., analog/digital I/O packs, power supplies), enabling scalable configurations for single or multi-turbine installations. Its firmware supports online application loading and parameter adjustments, allowing rapid adaptation to changing operational requirements without system downtime.

Wide Environmental Resilience: The module’s extended temperature range and rugged construction make it suitable for harsh industrial settings, including offshore platforms, refineries, and high-temperature power plants. Compliance with CE and UL standards ensures safety and reliability in regulated environments.

Application Areas: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

The GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C is pivotal in industries requiring precise turbine management and automation:

- Power Generation: Deployed in thermal, combined-cycle, and renewable energy plants to control steam and gas turbines, ensuring optimal power output, grid stability, and compliance with environmental regulations. The module’s real-time load balancing and excitation control optimize fuel efficiency and reduce emissions.

- Oil and Gas: Used in offshore platforms and refineries to manage turbine-driven compressors, pumps, and generators, enabling remote monitoring and control of critical processes in harsh, corrosive environments. Its rugged design and wide temperature range make it ideal for subsea and desert applications.

- Industrial Manufacturing: Integrates with turbine systems in chemical plants, paper mills, and cement facilities to manage energy-intensive processes, such as steam generation and mechanical drives. The module’s diagnostic capabilities support predictive maintenance and reduce operational costs.

- District Energy: Controls steam turbines in district heating and cooling networks, ensuring reliable energy distribution for commercial and residential complexes. Its precise regulation of turbine speed and output enhances system efficiency and responsiveness.

Related Products: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

- GE IS215UCVEM08: A later version of the UCVE controller with enhanced memory and firmware features, suitable for complex multi-turbine systems.

- GE IS215UCVEM01A: An earlier variant with similar hardware but limited memory, often used in simpler turbine setups.

- GE IS215ACLAH1A Excitation Control Module: A predecessor model focused on basic excitation control, compatible with the Mark VI series.

- GE IS215ACLEH1B Application Control Layer Module: An upgraded communication module with advanced protocol support, designed for large-scale automation networks.

- GE IS215DSPXH1A DSPX Excitation Controller: Works alongside the IS215UCVEH2AB to manage turbine excitation current and voltage regulation.

- GE IS215PARPH1A Power Supply Module: Delivers redundant power to the IS215UCVEH2AB and other Mark VI components, ensuring continuous operation during voltage fluctuations.

Installation and Maintenance: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

Pre-installation Preparations:

Before installing the IS215UCVEH2AB, ensure the VMEbus rack is properly grounded and the power supply (+5 VDC) meets specifications. Clean the rack slot and align the module with the backplane connectors, securing it with the provided brackets. Connect Ethernet cables to the dual ports and terminate power wires at the terminal block, following GE’s wiring diagrams to avoid polarity errors. Configure network settings (IP address, subnet mask) via the module’s front-panel interface or GE’s Proficy™ software. Verify compatibility with existing backplane configurations and ensure firmware versions match the system requirements.

Before installing the IS215UCVEH2AB, ensure the VMEbus rack is properly grounded and the power supply (+5 VDC) meets specifications. Clean the rack slot and align the module with the backplane connectors, securing it with the provided brackets. Connect Ethernet cables to the dual ports and terminate power wires at the terminal block, following GE’s wiring diagrams to avoid polarity errors. Configure network settings (IP address, subnet mask) via the module’s front-panel interface or GE’s Proficy™ software. Verify compatibility with existing backplane configurations and ensure firmware versions match the system requirements.

Maintenance Recommendations:

- Routine Inspections: Monthly checks for loose connections, damaged cables, or abnormal LED indicators. Use compressed air to clean dust from vents and cooling fins to prevent overheating. Monitor the module’s temperature and humidity levels to ensure they remain within specified limits.

- Firmware Updates: Annually update firmware using GE’s official tools to access new features, security patches, and compatibility enhancements. Back up configuration files before updates to ensure quick recovery if issues arise.

- Diagnostic Testing: Quarterly run built-in self-tests to verify communication ports, memory integrity, and CPU performance. Reference GE’s diagnostic codes to troubleshoot faults and replace faulty components promptly, leveraging our global supply chain for rapid replacement of discontinued parts.

- Spare Parts Management: Maintain a spare IS215UCVEH2AB in inventory, as our company’s extensive stock and 17 years of expertise ensure minimal downtime for critical repairs.

Product Guarantee: GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C

Our company provides a 12-month quality warranty for the GE IS215UCVEH2AB VMIVME-7614-132 350-007614-132C, covering non-human-induced hardware defects, such as communication failures, power supply malfunctions, or physical damage. During the warranty period, we will replace any defective module at no cost, ensuring uninterrupted operation of your critical systems. For urgent needs or discontinued models, our global logistics network and partnerships with GE authorized suppliers enable rapid fulfillment, even for rare or obsolete components.

With 17 years of specialization in industrial control distribution, we are committed to delivering reliable products and exceptional service. The IS215UCVEH2AB exemplifies our dedication to quality, offering robust control and communication capabilities for mission-critical turbine systems. Contact us today to optimize your automation infrastructure with this advanced module.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for GE’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200SPIDG1ABA | Power Interface Module | IS200SPIDG1ABA

GE IS200SPROH1AAB MRP663860 | Turbine Protection Relay Module | IS200SRTDH2ACB

GE IC660EPM100J Tachometer sensor

GE IC660TBA026 modbus card

GE IC660TBA026 Acquisition card

GE IC660TBD024 Gas turbine card

GE IC670CHS101 FIM card

GE IC670CPU350 Communication input interface component

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200SPIDG1ABA | Power Interface Module | IS200SPIDG1ABA

GE IS200SPROH1AAB MRP663860 | Turbine Protection Relay Module | IS200SRTDH2ACB

GE IC660EPM100J Tachometer sensor

GE IC660TBA026 modbus card

GE IC660TBA026 Acquisition card

GE IC660TBD024 Gas turbine card

GE IC670CHS101 FIM card

GE IC670CPU350 Communication input interface component

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: