Description

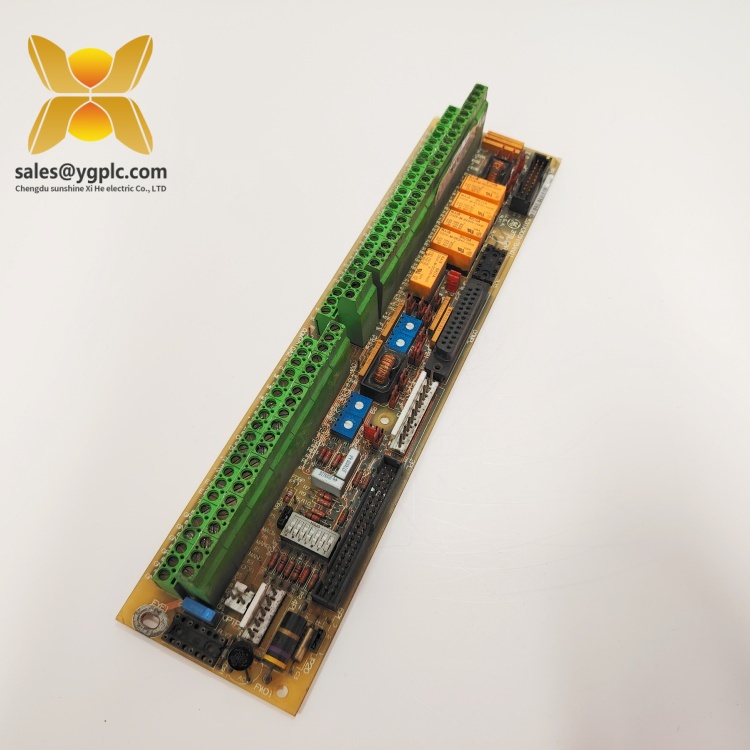

GE 531X305NTBANG1 Turbine Control I/O Module

Product Overview:GE 531X305NTBANG1

The GE 531X305NTBANG1 is a high-performance Turbine Control I/O Module designed for industrial automation systems, specifically as part of GE’s Mark VIe control platform for steam and gas turbines. Engineered to facilitate seamless interaction between field devices and the turbine control system, this module serves as a critical interface for analog and digital signal transmission, ensuring precise monitoring and control of turbine operations. The 531X305NTBANG1 integrates advanced signal conditioning and diagnostic capabilities, making it indispensable for maintaining operational efficiency and safety in power generation, oil & gas, and heavy manufacturing environments.

As a key component of the Mark VIe ecosystem, the GE 531X305NTBANG1 supports a wide range of input/output signals, including analog voltage/current, thermocouples, and discrete switches. Its modular design allows flexible configuration for the specific needs of turbine applications, such as speed regulation, vibration monitoring, and fuel control. The module’s robust construction and compatibility with GE’s Proficy software suite enable real-time data acquisition, remote diagnostics, and predictive maintenance, reducing downtime and extending equipment lifecycle. Whether deployed in standalone systems or integrated with distributed control systems (DCS), the 531X305NTBANG1 delivers reliable performance in harsh industrial conditions, including high temperatures, humidity, and electromagnetic interference.

The GE 531X305NTBANG1 plays a pivotal role in converting raw sensor data into actionable control signals, ensuring that turbines operate within safe and efficient parameters. Its dual-channel architecture supports redundant communication, enhancing system resilience in mission-critical applications. By combining high-precision signal processing with rugged industrial design, this module optimizes turbine performance, minimizes maintenance costs, and contributes to the overall reliability of industrial power generation and processing systems.

Technical Specifications:GE 531X305NTBANG1

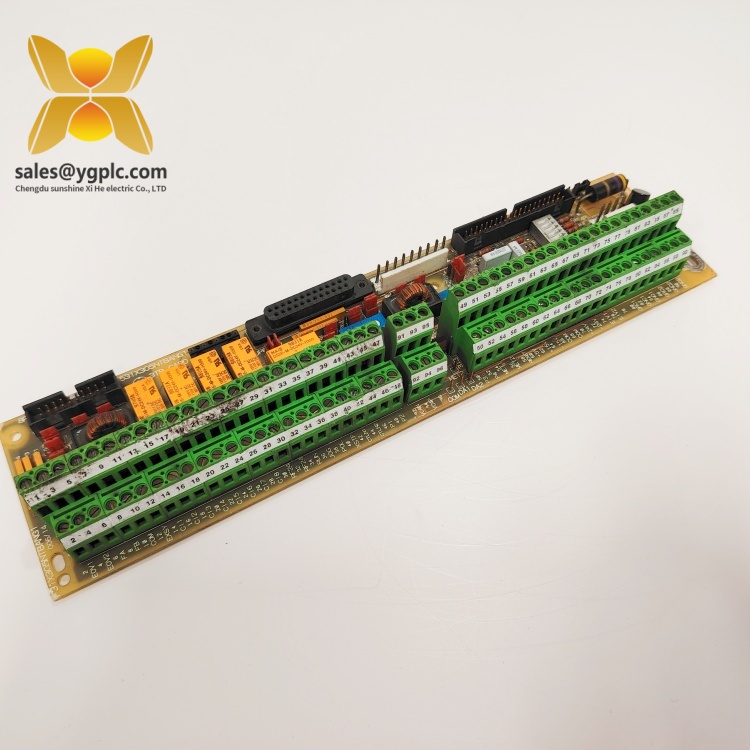

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 531X305NTBANG1 |

| Manufacturer | GE |

| Product Type | Turbine Control I/O Module |

| Platform | Mark VIe |

| Signal Types | Analog (4–20 mA, 0–10 V), Discrete (24 V DC), Thermocouple (J, K, T types) |

| Input/Output Channels | 16 channels (configurable as input or output) |

| Communication Protocol | Profibus DP, Ethernet/IP |

| Power Supply | 24 V DC ±10% (redundant) |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 2.1 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | 19-inch rack-mounted (standard industrial rack) |

| Certifications | CE, UL, IEC 61131-2 |

531X305NTBANG1

Key Features and Advantages:GE 531X305NTBANG1

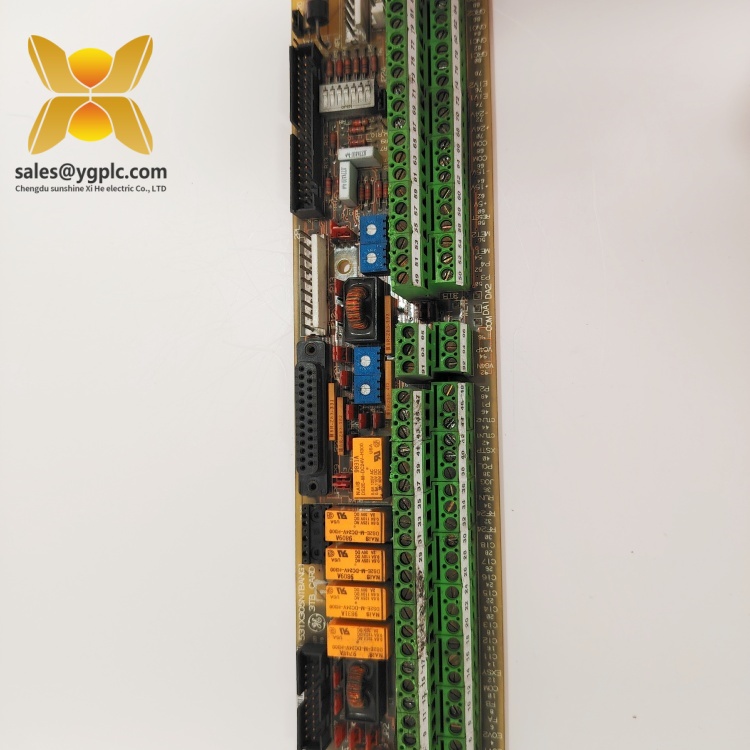

Flexible Signal Handling: The 531X305NTBANG1 supports a diverse range of input/output signals, eliminating the need for multiple specialized modules and simplifying system design. Its configurable channels allow seamless integration with sensors (e.g., pressure transducers, RTDs) and actuators (e.g., valves, relays), enhancing versatility in complex turbine control systems.

Redundant Architecture: With dual power inputs and communication paths, the module ensures continuous operation even in the event of a single component failure. This redundancy is critical for maintaining turbine control during maintenance or unexpected faults, reducing the risk of unplanned outages.

Advanced Diagnostics: Built-in self-diagnostic tools monitor signal integrity, power supply status, and module health in real time. LED indicators and digital fault codes provide immediate feedback, enabling rapid troubleshooting and minimizing mean time to repair (MTTR).

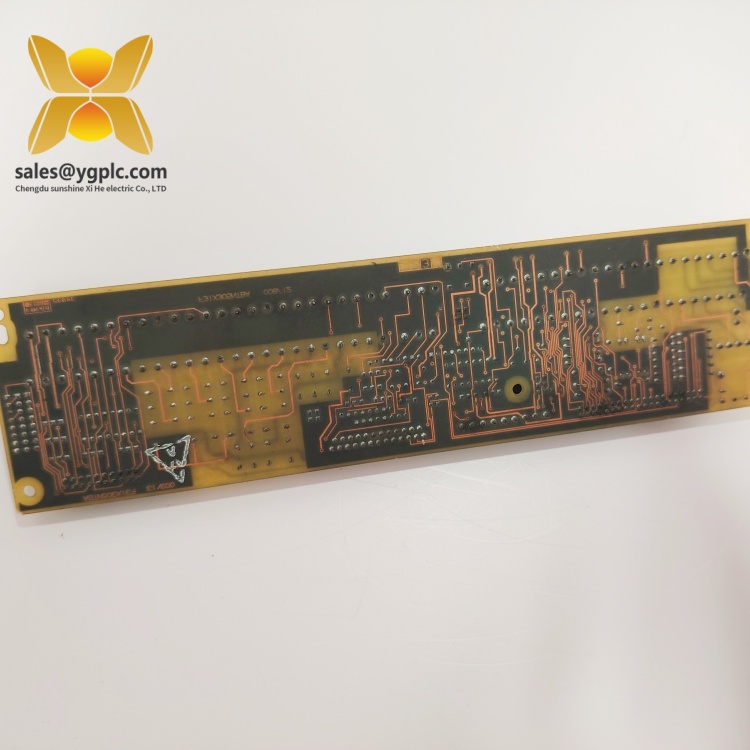

Rugged Industrial Design: The module’s metal enclosure and conformal coating protect against dust, moisture, and corrosive elements, while its wide temperature range and vibration resistance (IEC 60068-2-6) ensure reliable performance in harsh environments, such as power plant control rooms and offshore platforms.

Ease of Integration: Compatible with GE’s Mark VIe controllers and third-party systems via open protocols, the 531X305NTBANG1 simplifies integration into existing automation ecosystems. Its plug-and-play design and support for GE’s Proficy configuration software reduce installation time and configuration errors.

High Precision and Reliability: The module’s 16-bit analog-to-digital conversion ensures high-resolution signal processing, the critical parameter for precise turbine control. Its low latency and deterministic performance make it suitable for real-time control applications requiring rapid response to changing conditions.

531X305NTBANG1

Application Areas:GE 531X305NTBANG1

The GE 531X305NTBANG1 is widely deployed in industries where reliable turbine control and signal integration are essential:

- Power Generation: Monitors and controls steam and gas turbines in thermal, combined cycle, and hydroelectric power plants, managing parameters such as speed, load, and fuel flow to ensure grid stability and optimal energy production.

- Oil & Gas: Used in refineries, pipeline compression stations, and offshore platforms to regulate turbine-driven pumps and compressors, optimizing process efficiency and preventing overloading or overspeed conditions.

- Industrial Manufacturing: Supports turbine-based energy systems in chemical, pharmaceutical, and food processing plants, ensuring consistent power supply for energy-intensive processes and maintaining strict operational tolerances.

- Marine Engineering: Installed in marine gas turbines for large vessels, providing reliable control of propulsion systems and auxiliary machinery in dynamic marine environments.

Specific applications include:

- Vibration Monitoring: Integrates with accelerometers to detect abnormal turbine vibrations, enabling predictive maintenance to prevent mechanical failures.

- Valve Position Control: Provides analog output signals to regulate fuel or steam valves, optimizing combustion efficiency and reducing emissions.

- Emergency Shutdown Integration: Works with discrete input signals from safety sensors to trigger rapid shutdowns in response to critical faults, enhancing system safety.

531X305NTBANG1

Related Products:GE 531X305NTBANG1

- 531X306NTBANG1: A high-speed analog input module with enhanced sampling rates, ideal for applications requiring real-time vibration analysis alongside the 531X305NTBANG1.

- 531X304NTBANG1: A discrete I/O module with 32 channels, complementing the 531X305NTBANG1 in systems requiring a higher density of digital signal handling.

- IS210BPPCH1B: A redundant power supply module for Mark VIe systems, ensuring uninterrupted operation of the 531X305NTBANG1 during power fluctuations.

- IS210TCCVH1A: A vibration monitoring module that works in tandem with the 531X305NTBANG1 to provide comprehensive machinery health diagnostics.

- 531X310NTBANG1: A communication gateway module enabling Ethernet/IP connectivity for the 531X305NTBANG1 in modern industrial networks.

- IS200TSVIH1B: A temperature input module specializing in RTD and thermocouple signals, expanding the 531X305NTBANG1’s capability to handle diverse temperature monitoring tasks.

- 531X307NTBANG1: A relay output module for safety-critical shutdown applications, integrating with the 531X305NTBANG1 to provide fail-safe control logic.

- IS210CBLCH1A: High-reliability communication cables designed for low-latency signal transmission between the 531X305NTBANG1 and remote I/O racks.

Installation and Maintenance:GE 531X305NTBANG1

Installation Preparation:

Before installing the GE 531X305NTBANG1, ensure the Mark VIe rack is properly grounded and ventilated. Verify that the power supply meets the module’s specifications (24 V DC ±10%) and use shielded cables for signal connections to minimize electromagnetic interference. Mount the module in a designated slot within the rack, securing it with the provided screws. Use GE’s Proficy Machine Edition software to configure channel types, calibration parameters, and communication settings, ensuring compatibility with the existing control network.

Before installing the GE 531X305NTBANG1, ensure the Mark VIe rack is properly grounded and ventilated. Verify that the power supply meets the module’s specifications (24 V DC ±10%) and use shielded cables for signal connections to minimize electromagnetic interference. Mount the module in a designated slot within the rack, securing it with the provided screws. Use GE’s Proficy Machine Edition software to configure channel types, calibration parameters, and communication settings, ensuring compatibility with the existing control network.

Maintenance Recommendations:

- Routine Inspections: Conduct monthly visual checks to ensure secure connections and monitor for signs of overheating or physical damage. Clean the module’s vents with compressed air every quarter to prevent dust accumulation that could affect thermal performance.

- Calibration: Perform annual calibration of analog channels using certified test equipment to maintain measurement accuracy. Document calibration results for compliance and traceability.

- Firmware Updates: Periodically update the module’s firmware via GE’s official update tools to access new features, security patches, and performance improvements. Always back up configuration files before initiating updates.

- Spare Parts Management: Store spare 531X305NTBANG1 modules in static-free packaging at room temperature (20–25°C) with low humidity (<50%). Rotate inventory regularly to ensure components remain within their operational lifespan.

531X305NTBANG1

Product Warranty:GE 531X305NTBANG1

Our company provides a 12-month quality warranty for the GE 531X305NTBANG1, covering hardware defects under normal use. In the event of unexpected performance issues or functional failures, we offer prompt replacement services to minimize downtime. For discontinued or legacy models like the 531X305NTBANG1, our global supply chain network is specialized in sourcing rare and hard-to-find industrial control parts, ensuring quick turnaround for urgent requirements. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to keep your industrial systems operating reliably.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS420UCSBH1A Digital output module

GE IS220UCSAH1A Control system power supply

GE IS220UCSAH1AK Pressure transmitter

GE VMIVME-7455 Main frame

GE VMIVME-7750 VMIVME-7750-834 350-027750-834 A Expansion rack

GE IC695CPU320-CF Network communication module

GE IC687BEM731-AB DCS spare parts

GE IC698CHS009A PLC central processing unit

GE IC698CRE030-DE DO module

GE IC698PSA350E Control processor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: