Description

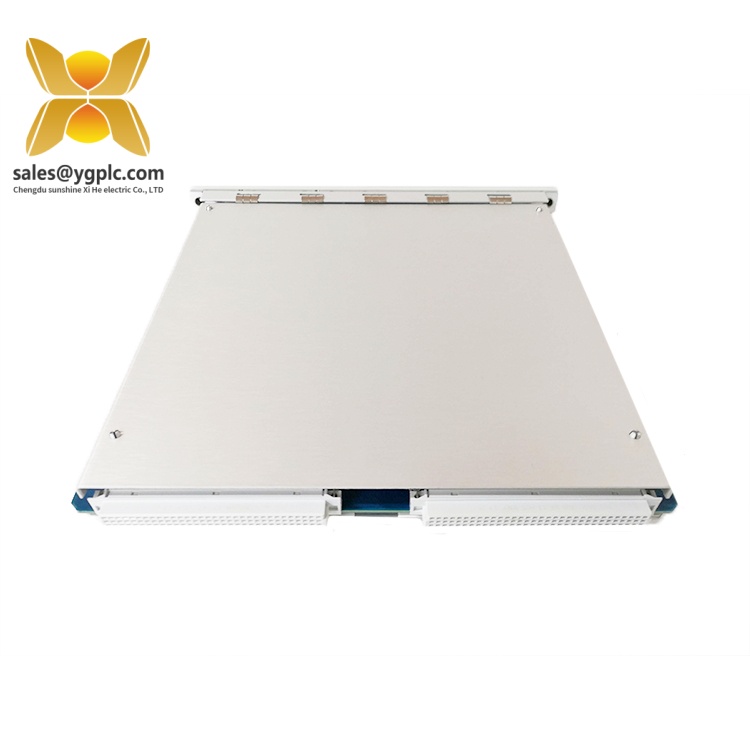

Product Overview:BENTLY NEVADA 3500/92 136180-01

Technical Specifications:BENTLY NEVADA 3500/92 136180-01

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/92 136180-01 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Communication Gateway Module |

| Input Voltage | 24V DC |

| Communication Protocols | Modbus TCP/IP, RS232/422/485 |

| Interface Type | 1 x RJ45 Ethernet, 2 x RS485 |

| Redundancy | Dual redundant channels |

| Physical Dimensions | 2.5 cm x 25.8 cm x 12 cm |

| Weight | 0.82 kg |

| Operating Temperature | -40°C to 85°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail |

| Protection Rating | IP20 |

| Country of Origin | United States |

3500/92 136180-01

Key Features and Advantages:BENTLY NEVADA 3500/92 136180-01

Scalable Integration: The 3500/92 136180-01 seamlessly integrates with Bently Nevada’s 3500 Series controllers and third-party systems, enabling scalable automation solutions. It supports hot-swappable functionality, allowing module replacement without disrupting system operation .

3500/92 136180-01

Application Areas:BENTLY NEVADA 3500/92 136180-01

- Power Generation: Integrates with Bently Nevada’s 3500 Series to manage data flow between gas/steam turbines, generators, and grid infrastructure. Enables remote monitoring of turbine vibration, temperature, and speed for predictive maintenance analytics .

- Oil & Gas: Facilitates communication between compressors, pumps, and control systems in refineries and offshore platforms. Supports real-time data exchange for process optimization and safety compliance .

- Industrial Manufacturing: Connects PLCs, robotics, and conveyor systems in smart factories, enabling centralized control and IoT-driven analytics. Ensures seamless integration with ERP and MES platforms .

- Water Treatment: Manages data transmission between pumps, valves, and SCADA systems in wastewater treatment plants, enhancing operational efficiency and regulatory compliance .

- Mining: Enables communication between crushers, conveyors, and ventilation systems in mining operations, improving safety and productivity through real-time monitoring .

Related Products:BENTLY NEVADA 3500/92 136180-01

- 3500/25 Keyphasor Module: A half-height module sets with the 3500/92 136180-01 to provide power and termination for keyphasor transducers, supporting speed and phase measurements in rotating machinery .

- 3500/42M Speed/Tachometer Module: A dual-channel module that interfaces with the 3500/92 136180-01 to monitor rotational speed and direction, expanding system diagnostic capabilities .

- 3500/53 Displacement Module: An analog input module that works alongside the 3500/92 136180-01 to measure shaft displacement and eccentricity in turbines and compressors .

- 3500/62 Process Variable Module: A multi-channel module that complements the 3500/92 136180-01 by monitoring process parameters (e.g., pressure, temperature) for comprehensive machinery health assessment .

- 3500/90 Communication Gateway Module: A legacy predecessor to the 3500/92 136180-01, offering similar functionality with a focus on Modbus RTU communication .

- 3500/05 Rack Enclosure: A hardware platform that houses the 3500/92 136180-01 and other 3500 Series modules, providing mechanical support and power distribution .

- 3500/15 Power Supply Module: A redundant power supply that ensures stable operation of the 3500/92 136180-01 and other 3500 Series components .

3500/92 136180-01

Installation and Maintenance:BENTLY NEVADA 3500/92 136180-01

Before installing the 3500/92 136180-01, verify the 24V DC power supply matches the module’s requirements. Clean the DIN rail and ensure proper grounding to minimize electromagnetic interference. Align the module with the rail and secure it using the provided mounting clips. Connect the power cables to the terminal block, ensuring torque specifications (35A max per terminal) are met. Finally, link the module to adjacent devices via the RJ45 Ethernet and RS485 ports, following Bently Nevada’s wiring guidelines .

- Routine Inspections: Quarterly check for loose connections, damaged cables, or signs of overheating. Clean the module’s surface to prevent dust accumulation .

- Firmware Updates: Periodically update the module’s firmware using Bently Nevada’s System 1 software to access new features and bug fixes .

- Connector Checks: Inspect Ethernet and RS485 connectors for corrosion or damage during annual maintenance. Re-seat connectors if necessary to ensure reliable signal transmission .

- Redundancy Testing: Test the dual communication channels bi-annually to confirm failover functionality. Replace faulty components immediately to maintain system resilience .

3500/92 136180-01

Product Warranty:BENTLY NEVADA 3500/92 136180-01

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and installation guidelines.

BENTLY 190065-00-01-03-01-01 PDP panel

BENTLY 350022 288055-01 programmable

BENTLY 135489-02 Logic controller

BENTLY 135031-01 Double output

BENTLY 3500/44M 140734-03 Expansion module

BENTLY 3500/54 133396-01 RXM rack

ABB DSDI110AV1 3BSE018295R1 CPU module

ABB PM866 Acquisition card

ABB PM864AK01 3BSE018161R1 Gas turbine card

ABB SCYC51010 58052515G DO module

Siemens 6DD2920-0AM0 AI card

Siemens 6DD2920-0BB0 Pulse encoder

HONEYWELL 51401497-100 FW25-92 Module connector

Bently 3500/44M 140734-03 03S Servo module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: