Description

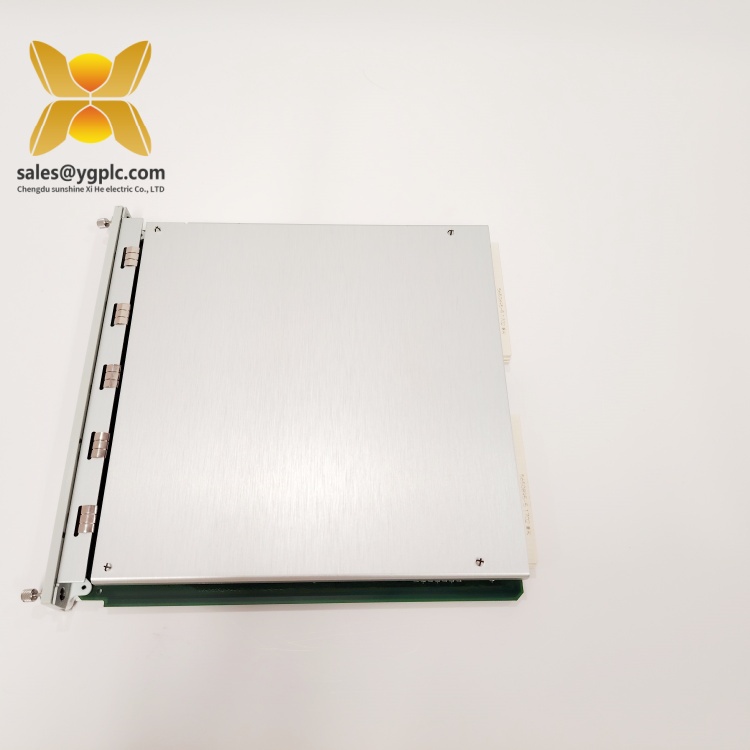

BENTLY NEVADA 3500/65 145988-02 Process Variable Module

Product Overview:BENTLY NEVADA 3500/65 145988-02

The BENTLY NEVADA 3500/65 145988-02 process variable module is a high-precision industrial component designed for real-time monitoring of critical process parameters within Bently Nevada’s 3500 Machinery Health Monitoring System. As a core module in the 3500 Series, it specializes in acquiring and processing analog signals from sensors measuring parameters such as temperature, pressure, flow, and level, ensuring seamless integration with rotating machinery control systems. This module plays a pivotal role in industrial automation by converting raw sensor data into actionable insights for predictive maintenance and process optimization.

Engineered to meet API 670 standards, the 3500/65 145988-02 features eight isolated analog input channels, each configurable to accept signals like 4–20 mA, RTD, or thermocouple inputs. Its dual redundant power supply and hot-swappable design minimize downtime, while the rugged aluminum enclosure ensures reliability in harsh environments, including high vibration, temperature fluctuations, and electromagnetic interference (EMI). The module’s Modbus RTU/TCP communication protocol enables real-time data transmission to supervisory control systems, making it an essential component for centralized monitoring in complex industrial setups.

Within automation systems, the 3500/65 145988-02 acts as a bridge between field sensors and the 3500 Rack, providing accurate and timely data to support decision-making. Its ability to handle both standard and custom sensor types enhances system flexibility, while built-in diagnostics and alarm setpoints enable proactive identification of anomalies. By ensuring precise measurement and reliable data integrity, this module contributes to improved equipment reliability, reduced maintenance costs, and enhanced operational safety across various industries.

Technical Specifications:BENTLY NEVADA 3500/65 145988-02

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/65 145988-02 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Process Variable Module |

| Input Channels | 8 isolated analog channels |

| Input Types | 4–20 mA, RTD (3-wire), thermocouple (J/K/T/E) |

| Power Supply | 24V DC (dual redundant) |

| Communication Protocol | Modbus RTU/TCP |

| Physical Dimensions | 160 mm (H) × 110 mm (W) × 250 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | 3500 Rack (19-inch standard) |

| Country of Origin | United States |

3500/65 145988-02

Main Features and Advantages:BENTLY NEVADA 3500/65 145988-02

Multi-Channel Flexibility: The 3500/65 145988-02 supports eight independent analog inputs, each to different sensor types without hardware reconfiguration. This versatility allows it to monitor a wide range of process variables simultaneously, reducing the need for multiple specialized modules and simplifying system architecture.

High Precision and Reliability: With ±0.1% accuracy across the entire input range, the module ensures precise measurement of critical parameters. Its galvanic isolation between channels prevents cross-talk and noise interference, while the rugged design complies with NEMA 4X/IP66 standards for protection against dust, moisture, and mechanical shocks.

Redundant and Hot-Swappable: The dual redundant power inputs and hot-swappable design enable maintenance or replacement without shutting down the entire system, ensuring continuous operation in mission-critical applications. This feature is particularly valuable in industries where downtime risks significant financial loss or safety hazards.

Advanced Diagnostics: Built-in self-test functions and LED status indicators provide real-time feedback on module health, including power supply status, communication errors, and sensor faults. This proactive diagnostic capability reduces troubleshooting time and supports predictive maintenance strategies.

Seamless Integration: As part of the 3500 Series, the module integrates effortlessly with other 3500 components, such as 3500/42M vibration monitoring modules and 3500/92 communication gateways. Its support for Modbus protocols ensures compatibility with third-party SCADA, DCS, and PLC systems, enabling scalable and interconnected automation solutions.

3500/65 145988-02

Application Areas:BENTLY NEVADA 3500/65 145988-02

The BENTLY NEVADA 3500/65 145988-02 process variable module is widely deployed in industries requiring precise monitoring and control of mechanical and process parameters:

- Power Generation: Used in steam and gas turbine systems to monitor temperatures of bearings, stator windings, and cooling systems, as well as pressures in lubrication and steam supply lines. This data supports optimal turbine performance and early detection of anomalies like overheating or leaks.

- Oil and Gas: Installed in refineries, pipelines, and offshore platforms to monitor process variables such as oil flow rates, compressor discharge pressures, and ambient temperatures. The module’s rugged design makes it suitable for harsh offshore environments with high humidity and salt exposure.

- Chemical and Pharmaceutical Manufacturing: Integrates with reactors, distillation columns, and mixing systems to monitor temperature profiles, pressure differentials, and liquid levels, ensuring process consistency and compliance with quality standards.

- Water and Wastewater Treatment: Monitors pump pressures, flow rates, and chemical concentrations in treatment plants, enabling efficient management of water distribution and wastewater processing while adhering to environmental regulations.

- Metallurgy and Mining: Deployed in heavy machinery like crushers and mills to monitor vibration levels, bearing temperatures, and material flow rates, optimizing equipment performance and reducing unplanned downtime in rugged mining environments.

Related Products:BENTLY NEVADA 3500/65 145988-02

- 3500/42M Vibration Monitoring Module: Works alongside the 3500/65 145988-02 to provide comprehensive machinery health monitoring, combining vibration analysis with process variable data for holistic asset management.

- 3500/22M Interface Module: Facilitates communication between the 3500 Rack and external devices, ensuring seamless data transfer from the 3500/65 145988-02 to supervisory control systems.

- 3500/32 Relay Module: Provides alarm and shutdown capabilities, triggering actions based on process variable thresholds monitored by the 3500/65 145988-02 to enhance system safety.

- 3500/53 Displacement Module: Complements the 3500/65 145988-02 by monitoring shaft displacement and eccentricity, offering the complete picture of machinery health when combined with process variable data.

- 3500/92 Communication Gateway: Enables Ethernet/IP and Modbus TCP connectivity for the 3500/65 145988-02, supporting integration with cloud-based analytics platforms and remote monitoring solutions.

- 3500/05 Rack Enclosure: Houses the 3500/65 145988-02 and other 3500 Series modules, providing mechanical support and centralized power distribution.

- 3500/15 Power Supply Module: Delivers stable 24V DC power to the rack, ensuring reliable operation of the 3500/65 145988-02 and its redundant power system.

3500/65 145988-02

Installation and Maintenance:BENTLY NEVADA 3500/65 145988-02

Pre-installation Preparations:

Before installing the 3500/65 145988-02, verify that the 3500 Rack is properly grounded and powered, with available slots for the module. Ensure all sensors connected to the module are calibrated and compatible with the selected input type (e.g., 4–20 mA for pressure transmitters or RTD for temperature sensors). Use shielded cables to minimize EMI and follow Bently Nevada’s wiring diagrams to connect sensor leads to the module’s terminal blocks, ensuring correct polarity and torque specifications.

Before installing the 3500/65 145988-02, verify that the 3500 Rack is properly grounded and powered, with available slots for the module. Ensure all sensors connected to the module are calibrated and compatible with the selected input type (e.g., 4–20 mA for pressure transmitters or RTD for temperature sensors). Use shielded cables to minimize EMI and follow Bently Nevada’s wiring diagrams to connect sensor leads to the module’s terminal blocks, ensuring correct polarity and torque specifications.

Maintenance Recommendations:

- Routine Inspections: Perform quarterly checks to ensure secure cable connections, clean the module’s ventilation slots to prevent dust accumulation, and verify LED status indicators for normal operation.

- Calibration: Annually calibrate the module using BENTLY NEVADA-certified tools to maintain measurement accuracy. For thermocouple inputs, check for oxidation or corrosion at connection points.

- Firmware Updates: Periodically review Bently Nevada’s official documentation for firmware updates that may enhance functionality or address compatibility issues with the 3500/65 145988-02.

- Redundancy Testing: Bi-annually test the dual power supply redundancy by simulating a power failure on one channel to ensure seamless failover to the backup supply.

3500/65 145988-02

Product Warranty:BENTLY NEVADA 3500/65 145988-02

Our company offers a 12-month quality warranty for the BENTLY NEVADA 3500/65 145988-02 process variable module, covering non-human-induced hardware defects. In the event of performance anomalies or functional failures during the warranty period, we provide prompt replacement services to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of spare parts, leveraging decades of expertise in industrial control distribution.

With 17 years of industry leadership, we are committed to delivering reliable, high-quality components supported by dedicated technical service. Whether optimizing machinery health in power plants or ensuring process integrity in manufacturing, the 3500/65 145988-02 exemplifies our commitment to empowering industrial excellence. Contact us today to explore how this module can enhance your automation system’s precision and reliability.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to Bently Nevada’s manuals for detailed installation and safety guidelines.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

BENTLY 190065-00-01-03-01-01 Power strip

BENTLY 350022 288055-01 Power source

BENTLY 135489-02 base

BENTLY 3500-20 exchange

BENTLY 135031-01 DI module

BENTLY 3500/44M 140734-03 AI card

BENTLY 3500/54 133396-01 Program module

WOODWARD 5466-318 Digital input module

WOODWARD 5466-425 Safety system module

WOODWARD 5501-381 Network communication card

ABB NAIO-03 Optical fiber interface board

ABB DSDP140B 57160001-ACX Logic controller

ABB SC520 3BSE003816R1 Control panel

ABB CS513 3BSE000435R1 Double output

ABB SPAJ110C Network communication

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: