Description

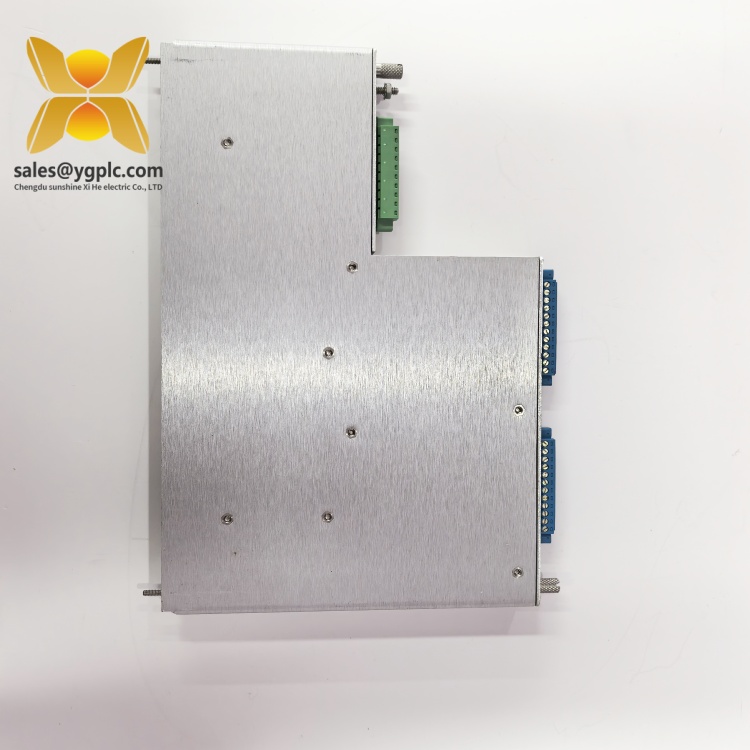

Product Overview:BENTLY NEVADA 135489-02

The BENTLY NEVADA 135489-02 is a high-performance I/O module designed for industrial machinery monitoring systems, specifically engineered to integrate seamlessly with the Bently Nevada 3500 Series platform. As a critical component of predictive maintenance solutions, this module provides advanced signal conditioning and data acquisition for rotating machinery, ensuring reliable health monitoring of turbines, compressors, generators, and other critical assets.

Engineered with precision, the 135489-02 features four independent channels: two Proximity/Acceleration (Prox/Accel) channels and two Velomitor channels. This configuration allows simultaneous monitoring of radial vibration, axial position, and velocity measurements, enabling comprehensive analysis of machinery dynamics. The module’s internal barriers and terminations eliminate the need for external signal isolation components, simplifying installation and reducing cabling complexity. By delivering real-time data on vibration amplitudes, phase angles, and temperature, the 135489-02 empowers engineers to detect early signs of mechanical degradation, minimizing unplanned downtime and extending equipment lifespan.

Built to withstand harsh industrial environments, the 135489-02 operates reliably in temperatures ranging from -20°C to +60°C and features an IP65-rated enclosure for protection against dust and water ingress. Its modular design ensures compatibility with the 3500 Series rack system, supporting hot-swappable replacement for seamless maintenance. With support for multiple communication protocols (e.g., RS485, Modbus RTU), the module facilitates integration with SCADA systems, DCS platforms, and cloud-based analytics tools, providing a unified view of machinery health across distributed networks.

Technical Specifications:BENTLY NEVADA 135489-02

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY NEVADA 135489-02 |

| Manufacturer | Bently Nevada |

| Product Type | I/O Module with Internal Barriers |

| Channel Configuration | 2 Prox/Accel + 2 Velomitor |

| Input Signal Range | Prox/Accel: 0–20 VDC; Velomitor: ±50 mV/g |

| Output Signal | 4–20 mA (isolated) |

| Communication Protocols | RS485, Modbus RTU |

| Power Supply | 24 VDC ±10% |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 160 mm (W) × 160 mm (H) × 120 mm (D) |

| Weight | 0.8 kg |

| Enclosure Rating | IP65 |

| Mounting Type | DIN rail (3500 Series rack-compatible) |

| Response Time | <10 ms |

| Data Storage | Built-in memory for 12 months of historical data |

135489-02

Key Features and Advantages:BENTLY NEVADA 135489-02

The BENTLY NEVADA 135489-02 stands out for its versatility and rugged performance. Its dual-channel Prox/Accel and Velomitor architecture supports simultaneous monitoring of multiple mechanical parameters, offering a holistic view of machinery health. The internal barriers provide galvanic isolation between input signals and the control system, protecting against ground loops and electromagnetic interference (EMI), while the integrated terminations reduce wiring complexity and installation time.

Reliability is a cornerstone of the 135489-02. The module’s wide operating temperature range and IP65 rating ensure consistent performance in extreme conditions, making it ideal for offshore platforms, refineries, and other harsh environments. Its self-diagnostic capabilities continuously monitor internal components, flagging potential issues before they escalate. Additionally, the module’s hot-swappable design allows for component replacement without disrupting system operation, minimizing downtime during maintenance.

Integration flexibility is another key strength. The 135489-02 supports industry-standard communication protocols, enabling seamless interoperability with third-party systems. Its compatibility with the 3500 Series rack system ensures scalability, allowing users to expand monitoring capabilities by adding modules as needed. The module’s user-friendly configuration software simplifies parameter setup and data visualization, empowering both experienced engineers and technicians to optimize monitoring strategies.

135489-02

Application Areas:BENTLY NEVADA 135489-02

The BENTLY NEVADA 135489-02 is widely deployed in industries where machinery reliability is critical. In power generation, it monitors steam turbines, gas turbines, and generators, providing real-time data on shaft vibration, bearing wear, and thermal expansion. This data supports predictive maintenance programs, reducing unplanned outages and optimizing equipment efficiency.

In oil and gas facilities, the 135489-02 safeguards compressors, pumps, and offshore rotating equipment by detecting imbalances, misalignments, and other mechanical faults. Its ability to operate in hazardous environments (Class I, Division 2 certified) makes it suitable for explosive atmospheres. Industrial manufacturing plants utilize the module to monitor motors, gearboxes, and conveyor systems, ensuring smooth production workflows and minimizing downtime.

Municipal water treatment facilities rely on the 135489-02 to monitor pumps and agitators, ensuring consistent water quality and operational stability. By integrating with plant-wide monitoring systems, the module contributes to sustainable practices by extending equipment life and reducing energy consumption.

Related Products:BENTLY NEVADA 135489-02

- BENTLY NEVADA 135489-01: A 4-channel Prox/Accel I/O module with internal barriers, ideal for applications requiring high-density vibration monitoring.

- BENTLY NEVADA 135489-03: A 4-channel Velomitor I/O module optimized for velocity measurements in high-speed machinery.

- BENTLY NEVADA 3500/42M Proximitor/Seismic Monitor: A companion module that processes signals from the 135489-02 to generate actionable alarms and trends.

- BENTLY NEVADA 3500/70M Communication Gateway: Enables remote access and data integration with enterprise systems via Ethernet TCP/IP.

- BENTLY NEVADA 3500/92 Display Unit: Provides local visualization of machinery health data from the 135489-02 and other 3500 Series modules.

- BENTLY NEVADA 3300 XL Proximitor Sensor: A complementary proximity probe system for accurate shaft displacement measurements.

- BENTLY NEVADA 3500/15 Power Supply Module: Ensures stable power delivery to the 135489-02 and other 3500 Series components.

- BENTLY NEVADA 3500/22M Bump Test Module: Validates sensor performance and system integrity during routine maintenance.

135489-02

Installation and Maintenance:BENTLY NEVADA 135489-02

Pre-Installation Preparation:

Before installing the 135489-02, verify compatibility with the 3500 Series rack and power supply. Ensure the environment meets the module’s temperature and humidity specifications. Clean the mounting surface and prepare tools such as a torque wrench and cable tester. Disconnect power to the rack and follow lockout/tagout procedures when retrofitting. Configure the module using the 3500 Rack Configuration Software, assigning channel parameters (e.g., sensor type, alarm thresholds) based on machinery requirements.

Before installing the 135489-02, verify compatibility with the 3500 Series rack and power supply. Ensure the environment meets the module’s temperature and humidity specifications. Clean the mounting surface and prepare tools such as a torque wrench and cable tester. Disconnect power to the rack and follow lockout/tagout procedures when retrofitting. Configure the module using the 3500 Rack Configuration Software, assigning channel parameters (e.g., sensor type, alarm thresholds) based on machinery requirements.

Maintenance Recommendations:

Regularly inspect the 135489-02 for physical damage or corrosion, particularly in harsh environments. Clean the enclosure exterior with a non-abrasive cloth. Calibrate sensors annually using certified calibration tools to maintain accuracy. Replace the desiccant cartridge every 12–18 months to prevent moisture ingress. Review historical data trends to identify gradual changes in vibration patterns, scheduling proactive maintenance as needed. Bently Nevada’s global support network provides technical assistance and replacement parts for optimal system performance.

Regularly inspect the 135489-02 for physical damage or corrosion, particularly in harsh environments. Clean the enclosure exterior with a non-abrasive cloth. Calibrate sensors annually using certified calibration tools to maintain accuracy. Replace the desiccant cartridge every 12–18 months to prevent moisture ingress. Review historical data trends to identify gradual changes in vibration patterns, scheduling proactive maintenance as needed. Bently Nevada’s global support network provides technical assistance and replacement parts for optimal system performance.

Product Warranty:BENTLY NEVADA 135489-02

Our company provides a one-year quality warranty for the BENTLY NEVADA 135489-02, covering hardware failures due to non-human factors. During the warranty period, we will replace any defective components free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce spare parts, supporting the continuous and stable operation of industrial systems. Our dedicated technical team offers 24/7 support to address installation, troubleshooting, and optimization needs, ensuring seamless integration and long-term reliability.

For inquiries, contact our sales team or visit our website for detailed product documentation and pricing.

BENTLY 190065-00-01-03-01-01 Main frame

BENTLY 350022 288055-01 Expansion rack

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

TRICONEX 7400213-100 System

TRICONEX DI3361 DCS

TRICONEX DO2401 7400209-030 rack

ABB 07KT98 GJR5253100R0278 Servo motor,

ABB 07KT97 GJR5253000R4270 Industrial keyboard

ABB NAIO-03 Optical fiber interface board

BENTLY 350022 288055-01 Expansion rack

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

TRICONEX 7400213-100 System

TRICONEX DI3361 DCS

TRICONEX DO2401 7400209-030 rack

ABB 07KT98 GJR5253100R0278 Servo motor,

ABB 07KT97 GJR5253000R4270 Industrial keyboard

ABB NAIO-03 Optical fiber interface board

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: