Description

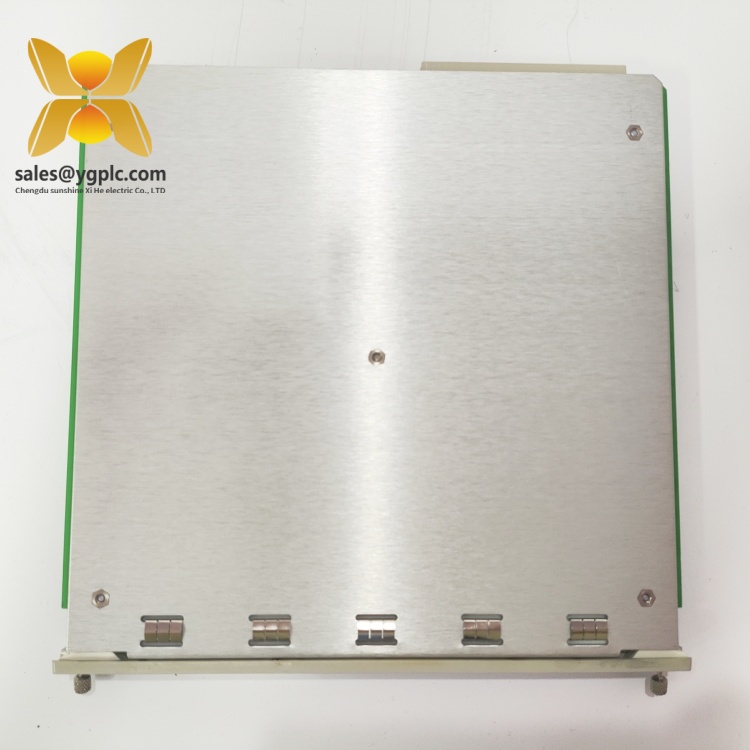

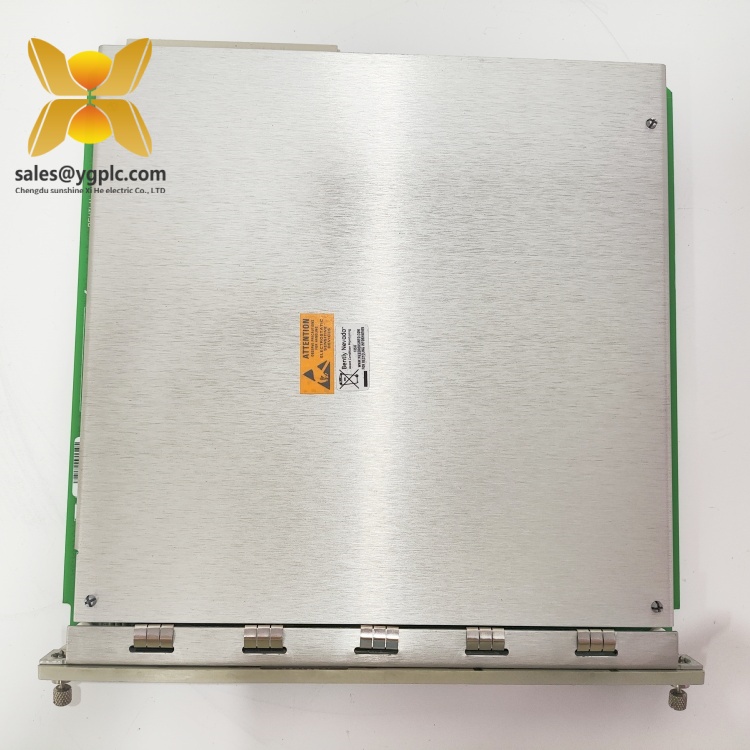

BENTLY 3500/32 125712-01 Relay Module

Product Overview: BENTLY 3500/32 125712-01

The BENTLY 3500/32 125712-01 relay module is a high-reliability industrial component designed for critical machinery protection within Bently Nevada’s 3500 Series Machinery Health Monitoring System. As a key element of this advanced platform, the 3500/32 125712-01 serves as a robust interface for alarm and trip functions, translating vibration and process data into actionable outputs for system safety and control. This module integrates seamlessly with other 3500 Series components, such as vibration monitors and communication gateways, to form a comprehensive machinery protection system.

Engineered for mission-critical applications, the 3500/32 125712-01 features 16 independent relay outputs (8 alarm and 8 trip), each configurable to respond to predefined thresholds from connected sensors. Its dual-redundant power supply (24V DC) and hot-swappable design ensure continuous operation even during maintenance, minimizing downtime in industrial environments. The module’s LED status indicators provide real-time feedback on relay states and fault conditions, while its Modbus RTU/TCP compatibility enables seamless integration with PLCs, DCS systems, and SCADA platforms for centralized monitoring.

In automation architectures, the 3500/32 125712-01 acts as a safety-critical component, ensuring rapid response to abnormal machinery conditions. By converting analog vibration measurements into digital relay signals, it facilitates timely shutdowns or adjustments to prevent equipment damage. Its rugged construction (IP20 protection, -40°C to +85°C operating range) and compliance with API 670 standards make it suitable for harsh industrial settings, including power plants, oil refineries, and manufacturing facilities.

Technical Specifications: BENTLY 3500/32 125712-01

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/32 125712-01 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Relay Module |

| Relay Outputs | 16 channels (8 alarm, 8 trip) |

| Power Supply | 24V DC (dual redundant) |

| Communication Protocol | Modbus RTU/TCP |

| Physical Dimensions | 160 mm (H) × 110 mm (W) × 250 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | 3500 Rack (slot-compatible) |

| Compliance | API 670, IEC 61000-6-2/-6-3 |

| Country of Origin | United States |

Main Features and Advantages: BENTLY 3500/32 125712-01

Redundant and Reliable Design: The 3500/32 125712-01 incorporates dual redundant power inputs, ensuring uninterrupted operation even if one power source fails. This redundancy is critical for applications where downtime could lead to significant financial loss or safety hazards, such as in turbine control systems.

Flexible Configuration: With 16 configurable relay outputs, the module allows users to define alarm and trip setpoints for each channel independently. This flexibility enables precise customization to match the specific protection requirements of different machines, from compressors to generators.

Real-Time Diagnostics: Built-in LED indicators provide instant visibility into relay status, power supply health, and communication integrity. This feature reduces troubleshooting time by allowing operators to quickly identify and resolve issues without specialized tools.

Hot-Swappable Functionality: The module’s hot-swappable design permits replacement while the system is running, eliminating the need for system shutdowns during maintenance. This feature enhances operational continuity and reduces mean time to repair (MTTR).

Industrial-Grade Durability: Designed to withstand harsh environments, the 3500/32 125712-01 features a rugged metal enclosure and wide temperature tolerance. It resists vibration, dust, and electromagnetic interference, ensuring reliable performance in challenging industrial settings.

Application Areas: BENTLY 3500/32 125712-01

The BENTLY 3500/32 125712-01 relay module is essential for industries requiring precise machinery protection and control:

- Power Generation: Installed in steam and gas turbine systems to trigger alarms or shutdowns in response to excessive vibration, ensuring safe operation and preventing catastrophic failures in power plants.

- Oil and Gas: Used in offshore platforms and refineries to monitor compressors and pumps, providing immediate relay outputs to isolate faulty equipment and maintain process safety in hazardous environments.

- Manufacturing: Integrated into production lines to protect high-value machinery, such as CNC machines and conveyor systems, by activating alarms or stopping operations when abnormal vibrations are detected.

- Water Treatment: Deployed in pump stations and wastewater treatment plants to ensure continuous operation by automatically responding to mechanical issues in critical equipment.

- Aerospace and Defense: Supports condition monitoring of aircraft ground support equipment, where reliable relay outputs are essential for maintaining operational readiness.

Related Products: BENTLY 3500/32 125712-01

- 3500/22M Interface Module: Connects the 3500/32 125712-01 to sensors and external devices, providing signal conditioning for vibration and displacement measurements.

- 3500/42M Vibration Monitoring Module: Works alongside the 3500/32 125712-01 to analyze vibration data and trigger relay actions based on predefined thresholds.

- 3500/92M Communication Gateway: Enables Ethernet-based communication between the 3500/32 125712-01 and supervisory systems, facilitating remote monitoring and control.

- 3500/05 Rack Enclosure: Houses the 3500/32 125712-01 and other 3500 Series modules, providing mechanical support and power distribution.

- 3500/15 Power Supply Module: Provides redundant power to the 3500/32 125712-01 and other rack-mounted components, ensuring stable operation.

- 3500/53 Displacement Module: Complements the 3500/32 125712-01 by monitoring shaft displacement and transmitting data for relay activation.

Installation and Maintenance: BENTLY 3500/32 125712-01

Pre-installation Preparations:

Before installing the 3500/32 125712-01, ensure the 3500 Rack is properly grounded and powered. Verify that the power supply (24V DC) matches the module’s requirements and that all wiring complies with Bently Nevada’s specifications. Clean the rack slot and ensure no debris is present. Slide the module into the designated slot, ensuring it clicks into place, and secure it with the provided retention brackets. Connect the power cables and relay output wires to the terminal blocks, following the wiring diagram in the user manual.

Before installing the 3500/32 125712-01, ensure the 3500 Rack is properly grounded and powered. Verify that the power supply (24V DC) matches the module’s requirements and that all wiring complies with Bently Nevada’s specifications. Clean the rack slot and ensure no debris is present. Slide the module into the designated slot, ensuring it clicks into place, and secure it with the provided retention brackets. Connect the power cables and relay output wires to the terminal blocks, following the wiring diagram in the user manual.

Maintenance Recommendations:

- Routine Inspections: Monthly checks should include verifying LED status indicators, tightening cable connections, and cleaning the module’s surface to prevent dust accumulation.

- Functional Testing: Quarterly testing of relay outputs using a calibrated signal source ensures they respond correctly to alarm and trip thresholds.

- Firmware Updates: Periodically update the module’s firmware via the 3500 Rack Configuration Software to access the latest features and bug fixes.

- Spare Parts Management: Keep a spare 3500/32 125712-01 on hand for quick replacement. Ensure the spare module is pre-configured to minimize downtime in case of failure.

Product Guarantee: BENTLY 3500/32 125712-01

Our company provides a 12-month quality warranty for the BENTLY 3500/32 125712-01 relay module, covering hardware defects arising from non-human factors. During the warranty period, we will promptly replace any module that exhibits faulty relay operation, power supply issues, or communication failures. For discontinued models or urgent needs, our global supply chain network ensures rapid delivery of scarce components, minimizing disruptions to your operations.

With 17 years of expertise in industrial control distribution, we are committed to delivering reliable solutions and exceptional customer support. The 3500/32 125712-01 exemplifies our dedication to quality and performance, providing the safety and reliability required for critical machinery protection. Contact us today to discuss how this module can enhance your automation system’s safety and efficiency.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for Bently Nevada’s official technical documentation. Always refer to the manufacturer’s guidelines for detailed installation and operation instructions.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

BENTLY 3500/44M 140734-03 Analog input

BENTLY 3500/54 133396-01 Control cabinet node unit

BENTLY 3500/92 136180-01 governor

BENTLY 3500/15 114M5330-01 Input module

BENTLY 3500/77M 176449-07 AI/AO/DI/DO module

BENTLY 3500/54 133396-01 Connecting module

BENTLY 190065-00-01-03-01-01 PDP panel

BENTLY 350022 288055-01 programmable

BENTLY 135489-02 Logic controller

BENTLY 135031-01 Double output

BENTLY 3500/54 133396-01 Control cabinet node unit

BENTLY 3500/92 136180-01 governor

BENTLY 3500/15 114M5330-01 Input module

BENTLY 3500/77M 176449-07 AI/AO/DI/DO module

BENTLY 3500/54 133396-01 Connecting module

BENTLY 190065-00-01-03-01-01 PDP panel

BENTLY 350022 288055-01 programmable

BENTLY 135489-02 Logic controller

BENTLY 135031-01 Double output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: