Description

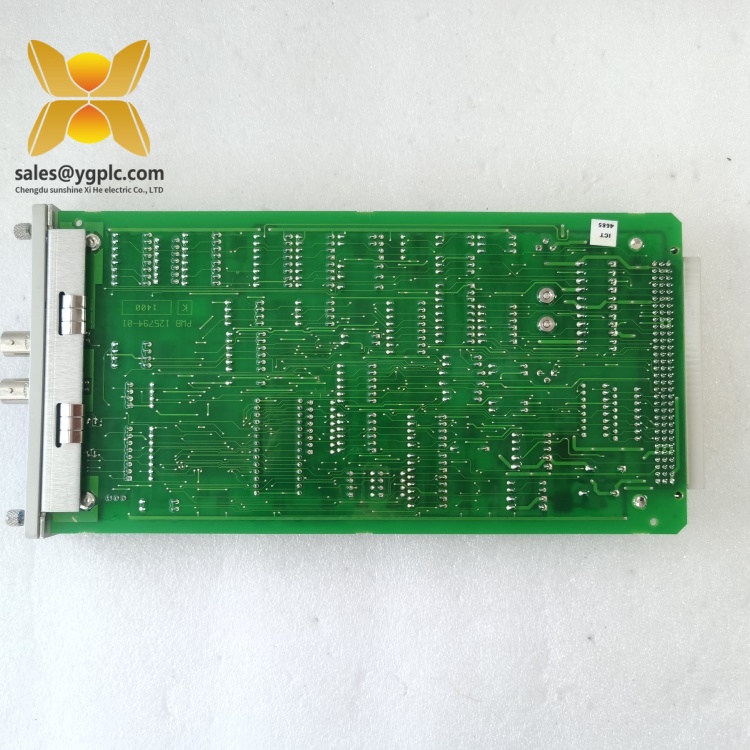

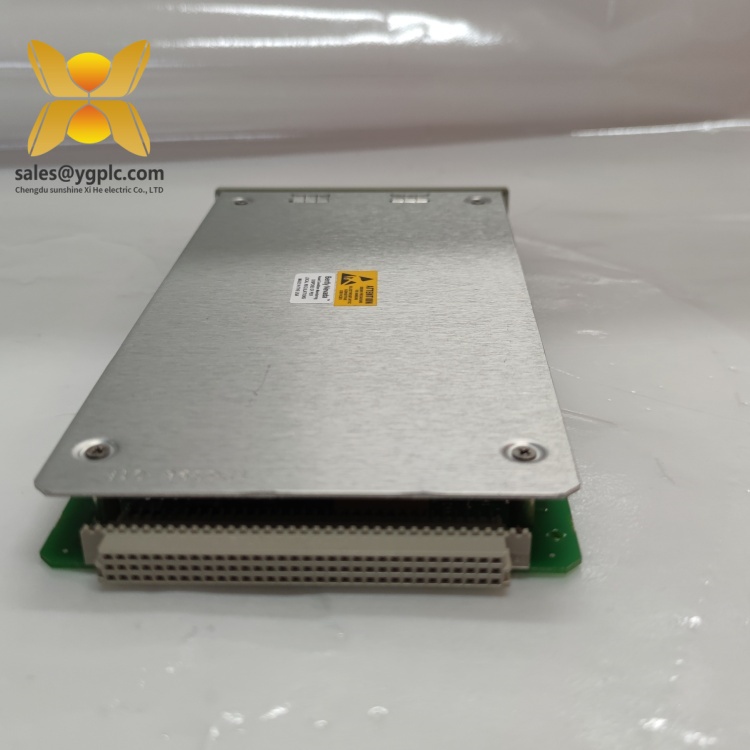

BENTLY 3500/25 125792-01 Keyphasor Module

Product Overview

The BENTLY 3500/25 125792-01 is a high-precision Keyphasor Module designed as a critical component of Bently Nevada’s 3500 Series Machinery Protection System. Engineered to provide precise rotational speed and phase reference signals for rotating equipment, this module plays a fundamental role in vibration analysis, balancing, and synchronization of turbines, compressors, and generators across industries such as oil & gas, power generation, and manufacturing. As part of the 3500 Series, the 3500/25 125792-01 integrates seamlessly with other monitoring modules (e.g., vibration monitors, communication gateways) to form a comprehensive machinery health management ecosystem, ensuring reliable operation and early fault detection in mission-critical applications.

Featuring a rugged industrial design, the BENTLY 3500/25 125792-01 supports dual-channel input from proximity probes or optical sensors, delivering accurate keyphasor signals for phase-locked vibration measurements. Its configurable threshold settings and real-time diagnostic feedback via the 3500 Series rack interface enhance operational visibility, allowing engineers to detect early signs of equipment degradation. The module’s wide speed range (0–50,000 RPM) and phase accuracy within ±0.1° at constant speed make it suitable for both low-speed and high-speed machinery, while its compatibility with industry standards like API 670 ensures compliance with safety and reliability requirements.

In automation systems, the 3500/25 125792-01 serves as the timing reference for vibration analysis, enabling accurate assessment of shaft dynamics and component alignment. Its redundant design and rugged enclosure (IP54-rated) ensure reliable performance in harsh environments, including high temperatures, vibration, and electromagnetic interference. By providing precise rotational data, this module optimizes machinery performance, minimizes unplanned downtime, and extends the lifecycle of high-value assets, making it an indispensable component for predictive maintenance strategies.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/25 125792-01 |

| Manufacturer | Bently Nevada |

| Product Type | Keyphasor Module |

| Input Signals | Proximity probes (8–24 VDC excitation) or optical sensors (NPN/PNP) |

| Output Signals | TTL/CMOS digital, 4–20 mA analog (optional) |

| Speed Range | 0–50,000 RPM |

| Phase Accuracy | ±0.1° at constant speed |

| Physical Dimensions | 10.16 cm (H) × 16.51 cm (W) × 22.86 cm (D) |

| Weight | 0.8 kg |

| Power Supply | 19.2–26.4 VDC |

| Communication | Proprietary 3500 Series bus (compatible with MODBUS via 3500/92 gateway) |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in 3500 Series enclosure |

Key Features and Advantages

Dual-Channel Redundancy: The 3500/25 125792-01 features two independent input channels, allowing simultaneous monitoring of primary and backup sensors. This redundancy eliminates single points of failure, ensuring continuous operation during sensor maintenance or replacement.

High-Precision Timing: With phase accuracy within ±0.1° and speed resolution down to 0.1 RPM, the module provides reliable reference signals for advanced vibration analysis, such as order tracking and modal testing. This precision is critical for identifying subtle mechanical issues like misalignment or bearing wear.

Flexible Sensor Compatibility: The module supports both proximity probes (for contactless metal detection) and optical sensors (for non-metallic targets), adapting to diverse machinery setups. Its configurable input filters reduce noise from harmonic interference, enhancing signal integrity in high-vibration environments.

Integrated Diagnostics: Built-in self-test features continuously monitor sensor health, power supply stability, and signal validity. Alarms and fault codes are transmitted to the rack’s main processor, enabling rapid troubleshooting and reducing mean time to repair (MTTR).

Rugged Industrial Design: The module’s reinforced metal enclosure and conformal-coated circuitry withstand extreme temperatures, humidity, and shock (up to 15 g), making it suitable for offshore platforms, refineries, and other harsh industrial environments.

Seamless System Integration: As part of the 3500 Series, the 3500/25 125792-01 interfaces with Bently Nevada’s 3500/44M configuration software, allowing intuitive setup of trigger levels, signal scaling, and alarm parameters. Its compatibility with the 3500/92 communication gateway enables integration with DCS or SCADA systems for remote monitoring.

Application Areas

The BENTLY 3500/25 125792-01 is essential in industries where precise rotational monitoring is non-negotiable:

- Oil & Gas: Monitors shaft speed and phase in compressors, pumps, and turbines to detect imbalance or cavitation, ensuring safe and efficient operation in upstream, midstream, and downstream facilities.

- Power Generation: Provides timing references for steam and gas turbines in power plants, supporting synchronization with the electrical grid and optimizing generator performance during load changes.

- Manufacturing: Controls rotational speed in high-speed motors, fans, and conveyor systems, preventing mechanical overload and ensuring consistent production quality in automotive, chemical, and food processing plants.

- Aerospace & Defense: Used in test stands and propulsion systems to analyze engine dynamics, ensuring compliance with rigorous safety and performance standards.

Specific applications include:

- Vibration Analysis: Enables phase-locked data acquisition for accelerometers and displacement probes, facilitating detailed fault diagnosis through tools like orbit plots and waterfall diagrams.

- Balancing Operations: Provides the reference signal for dynamic balancing of rotating components, reducing vibration levels and extending bearing life.

- Machine Synchronization: Coordinates multiple drives in complex systems, such as multi-motor conveyor networks, to maintain precise speed matching and prevent material spillage or equipment damage.

Related Products

- 3500/22M Keyphasor Module: A complementary model with enhanced frequency range for high-speed applications, often used alongside the 3500/25 125792-01 in specialized machinery setups.

- 3500/42M Vibration Monitor: Works in tandem with the 3500/25 125792-01 to analyze vibration amplitude and phase, providing a comprehensive view of machinery health.

- 3500/92 Communication Gateway: Enables Ethernet/MODBUS connectivity for the 3500/25 125792-01, allowing remote data access and integration with enterprise-level monitoring systems.

- 3300 XL Proximity Probes: Paired with the module for non-contact speed measurement, offering reliable performance in harsh conditions.

- 3500/05 Rack Enclosure: Houses the 3500/25 125792-01 and other 3500 Series modules, providing a centralized and protected environment for monitoring hardware.

- 3500/32M Relay Module: Triggers alarms or shutdowns based on keyphasor-derived speed thresholds, enhancing safety in critical processes.

Installation and Maintenance

Pre-installation Preparations:

Before installing the BENTLY 3500/25 125792-01, ensure the 3500 Series rack is properly grounded and powered. Verify sensor compatibility (proximity or optical) and route shielded cables to minimize electromagnetic interference. Use Bently Nevada’s 3500/44M software to configure channel parameters, such as sensor type, trigger level, and alarm setpoints. Mount the module in the rack using the provided hardware, ensuring adequate airflow for thermal management.

Before installing the BENTLY 3500/25 125792-01, ensure the 3500 Series rack is properly grounded and powered. Verify sensor compatibility (proximity or optical) and route shielded cables to minimize electromagnetic interference. Use Bently Nevada’s 3500/44M software to configure channel parameters, such as sensor type, trigger level, and alarm setpoints. Mount the module in the rack using the provided hardware, ensuring adequate airflow for thermal management.

Maintenance Suggestions:

- Routine Inspections: Perform quarterly checks to confirm secure connections, clean the module’s vents, and verify LED status indicators. Document any deviations from normal operating parameters.

- Calibration: Annually calibrate the module using Bently Nevada’s calibration fixtures to ensure signal accuracy. Compare measured speed and phase values against reference standards and adjust as needed.

- Firmware Updates: Periodically update the module’s firmware via the 3500 Series software to access bug fixes and new features, following the manufacturer’s step-by-step guidelines.

- Spare Parts Management: Store spare 3500/25 125792-01 modules in a controlled environment (temperature: 10–30°C, humidity: <50%) to ensure rapid replacement during unexpected failures.

Product Guarantee

Our company provides a 12-month quality warranty for the BENTLY 3500/25 125792-01, covering hardware defects under normal use. In the event of performance issues, we offer prompt replacement services to minimize downtime. For discontinued or legacy models like the 3500/25 125792-01, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to maintain your machinery protection systems’ reliability.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

BENTLY 135489-02 Input module

BENTLY 3500-20 AI/AO/DI/DO module

BENTLY 135031-01 Servo valve

BENTLY 3500/92 136180-01 Double output

BENTLY 3500/15 114M5330-01 Expansion module

BENTLY 3500/77M 176449-07 RXM rack

BENTLY 3500/54 133396-01 Thermoelectric couple

BENTLY 3500/32 125720-01 Double-action switch

BENTLY 3500/45 176449-04 S100

BENTLY 190065-00-01-03-01-01 Main frame

BENTLY 350022 288055-01 Expansion rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: