Description

BENTLY 3500/15 114M5335-01 Product Specification

Product Overview

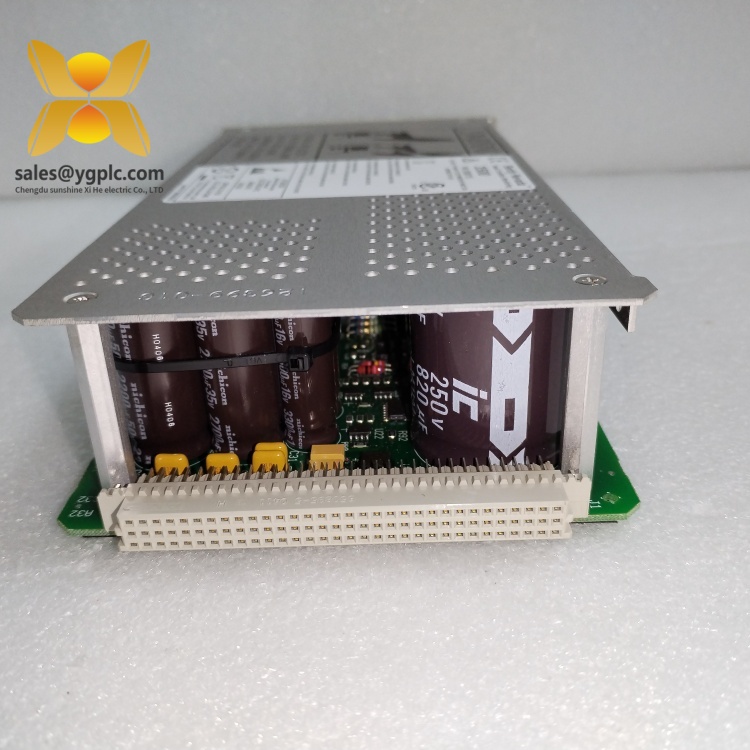

The BENTLY 3500/15 114M5335-01 is a high-reliability low-voltage AC power input module (PIM) designed for BENTLY’s 3500 Series Machinery Protection System. Engineered to convert incoming AC voltage into a stable DC power supply, this module serves as a foundational component in industrial automation systems, ensuring reliable power delivery to other modules within the 3500 series rack. The BENTLY 3500/15 114M5335-01 supports a wide input voltage range and features advanced power regulation, making it essential for industries such as oil and gas, power generation, and manufacturing where uninterrupted operation is critical.

As part of BENTLY NEVADA’s 3500 platform, the BENTLY 3500/15 114M5335-01 integrates seamlessly with vibration monitors, communication gateways, and other control modules to form a comprehensive machinery protection system. Its compact design (210 mm × 150 mm × 100 mm) and lightweight construction (2 kg) facilitate easy installation in 19″ racks, while the IP23-rated enclosure protects against dust and moisture. The module’s fail-safe design ensures stable power output even during voltage fluctuations, minimizing downtime and enhancing system reliability.

In automation architectures, the BENTLY 3500/15 114M5335-01 acts as a power management hub, providing 24 VDC to critical components like vibration sensors and communication modules. Its built-in diagnostic capabilities monitor power status and alert operators to anomalies, enabling proactive maintenance. By combining robust power regulation with rugged industrial design, the module supports predictive maintenance strategies and ensures the continuous operation of high-value rotating machinery.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3500/15 114M5335-01 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Low-Voltage AC Power Input Module (PIM) |

| Input Voltage | 85–264 VAC RMS (nominal 110–220 VAC) |

| Input Frequency | 47–63 Hz |

| Output Voltage | 24 VDC ±10% |

| Power Consumption | <15 W |

| Communication Interface | RS-485 (optional) |

| Physical Dimensions | 210 mm (W) × 150 mm (H) × 100 mm (D) |

| Weight | 2.1 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, CSA |

Main Features and Advantages

Wide Voltage Compatibility: The BENTLY 3500/15 114M5335-01 supports a broad input voltage range (85–264 VAC), adapting to diverse power supply environments without additional converters. This flexibility reduces installation complexity and ensures compatibility with global power grids, making it ideal for multinational industrial projects.

Reliable Power Regulation: The module maintains stable 24 VDC output during voltage spikes or sags, safeguarding downstream components from damage. Its overcurrent and thermal protection mechanisms enhance system longevity by preventing overloads in high-demand scenarios, such as during peak operational loads in manufacturing facilities.

Optional Communication Interface: With optional RS-485 connectivity, the BENTLY 3500/15 114M5335-01 enables remote monitoring of power status. Engineers can track voltage fluctuations and module health via SCADA systems, supporting predictive maintenance and reducing the need for on-site inspections in hard-to-reach locations like offshore platforms.

Rugged Industrial Design: Constructed with an IP23-rated enclosure and conformal-coated PCBs, the module resists dust, moisture, and electromagnetic interference (EMI). Its wide operating temperature range ensures reliable performance in harsh environments, from the extreme cold of arctic oil fields to the high temperatures of power plant control rooms.

Modular System Integration: As part of the 3500 Series, the BENTLY 3500/15 114M5335-01 integrates seamlessly with other modules (e.g., vibration monitors, communication gateways), forming a cohesive protection system. This modularity allows for easy expansion, enabling industries to scale their automation setups as operational needs evolve.

Application Areas

The BENTLY 3500/15 114M5335-01 is critical in industries where stable power is non-negotiable:

-

Oil and Gas:

- Powers emergency shutdown systems (ESD) in refineries and offshore platforms, ensuring safe operation during critical processes like crude oil distillation. It supports continuous monitoring of pipeline compressors by supplying reliable power to vibration sensors that detect early signs of mechanical wear.

-

Power Generation:

- Maintains stable power for turbine control systems in thermal and renewable energy plants, enabling real-time adjustments to optimize energy production. The module ensures uninterrupted operation of generator monitoring systems, preventing downtime caused by power fluctuations in grid-connected infrastructure.

-

Manufacturing:

- Powers robotic arms and high-speed conveyor systems in automotive plants, ensuring precise motion control and reducing production losses due to unexpected power interruptions. In pharmaceutical facilities, it supports sterile processing equipment by maintaining consistent power for quality control sensors.

-

Water/Wastewater Treatment:

- Controls pump stations and chemical dosing systems by providing reliable power to PLCs and flow meters, maintaining consistent water treatment efficiency. It enables remote monitoring of distributed water facilities via SCADA, supporting proactive maintenance in municipal water networks.

- Controls pump stations and chemical dosing systems by providing reliable power to PLCs and flow meters, maintaining consistent water treatment efficiency. It enables remote monitoring of distributed water facilities via SCADA, supporting proactive maintenance in municipal water networks.

Related Products

- BENTLY 3500/15 125840-02: A legacy power input module with similar functionality, often used as a direct replacement for the BENTLY 3500/15 114M5335-01 in older 3500 Series systems.

- BENTLY 3500/95 129411-01: A redundant power supply module that pairs with the BENTLY 3500/15 114M5335-01 to create a fail-safe power system, ideal for mission-critical applications like nuclear power plant turbines.

- BENTLY 3500/22M 146031-01: A vibration monitoring module that relies on the BENTLY 3500/15 114M5335-01 for stable power, enabling comprehensive machinery health analysis in refinery compressors.

- BENTLY 3500/92 129410-01: A communication gateway module that integrates with the BENTLY 3500/15 114M5335-01 to enable remote power diagnostics via Ethernet/IP, supporting Industry 4.0 initiatives in smart factories.

- BENTLY 3500/32 129407-01: A speed/torque monitor that works in tandem with the BENTLY 3500/15 114M5335-01 to provide rotational data for steam turbine control systems in power plants.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 3500/15 114M5335-01, ensure the following:

Before installing the BENTLY 3500/15 114M5335-01, ensure the following:

- Verify the input voltage matches the module’s range (85–264 VAC) and that the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability and phase balance before connecting the module.

- If using RS-485 communication, configure the module’s baud rate (up to 115.2 kbps) and parity settings via BENTLY’s proprietary software to match the system’s network parameters. This ensures seamless integration with supervisory control systems.

- Mount the module in a 19″ rack with at least 50 mm of clearance for airflow, securing it with the provided stainless-steel brackets to minimize vibration-induced displacement in high-motion environments like manufacturing floors.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and cleaning of dust from ventilation slots using a non-conductive brush. This prevents overheating in dusty environments like cement plants or grain processing facilities.

- Voltage Monitoring: Quarterly verification of input and output voltages using a calibrated multimeter to ensure compliance with specifications. Record data to identify trends and address potential issues before they escalate.

- Firmware Updates: Periodically update the module’s firmware via BENTLY’s software to access bug fixes and compatibility improvements, especially when integrating with newer 3500 Series components or upgrading to smart grid systems.

- Redundancy Testing: Biannual functional tests of redundant power configurations (if applicable) to ensure failover capability during power supply interruptions, critical for maintaining uptime in 24/7 operations like data center cooling systems.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 3500/15 114M5335-01, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits abnormal power output or functional defects. For discontinued models like the BENTLY 3500/15 114M5335-01, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services, leveraging our network of certified technicians to maintain your system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from BENTLY’s official specifications and industry applications. For detailed installation guidelines, refer to the BENTLY 3500/15 114M5335-01 user manual or contact our technical support team for personalized assistance.

BENTLY 190065-00-01-03-01-01 Dual digital output module

BENTLY 350022 288055-01 Card piece

BENTLY 135031-01 rack

BENTLY 3500/44M 140734-03 Remote module

BENTLY 3500/54 133396-01 Main processor

BENTLY 3500/92 136180-01 Pulse input

BENTLY 190065-00-01-03-01-01 System

BENTLY 350022 288055-01 DCS

BENTLY 135489-02 rack

BENTLY 135031-01 Main processor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: