Description

BENTLY 330103-00-03-05-02-05 Product Specification

Product Overview

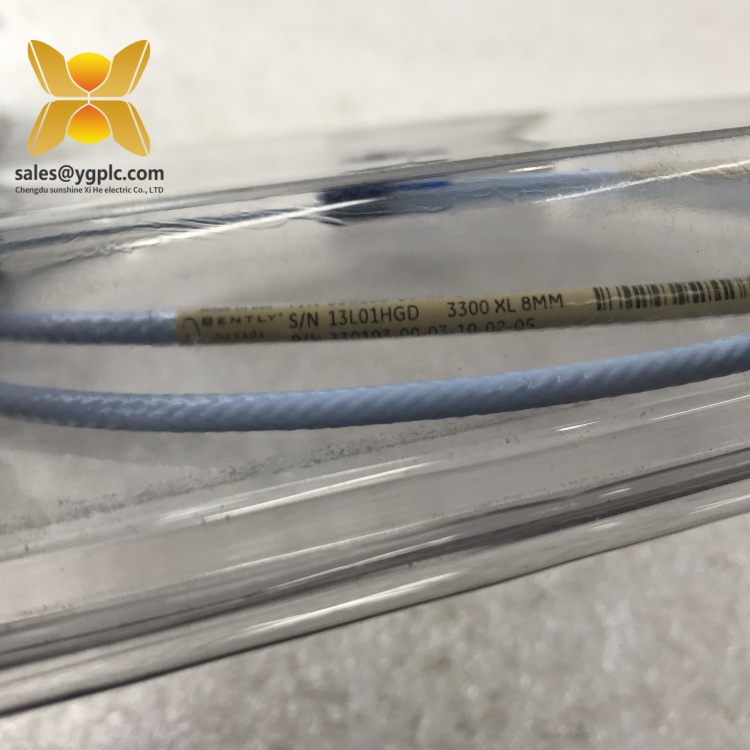

The BENTLY 330103-00-03-05-02-05 is a high-precision eddy current proximity probe engineered for BENTLY’s 3300 Series Machinery Protection System. Designed to monitor shaft displacement and vibration in rotating equipment, this probe serves as a critical component in industrial automation systems across industries such as oil and gas, power generation, and manufacturing. The BENTLY 330103-00-03-05-02-05 features a 5 mm probe diameter and 3 m PTFE-insulated cable, enabling precise non-contact measurements of shaft movement with a linear range of 0–2500 μm. As part of the 3300 Series, it integrates seamlessly with BENTLY’s monitor modules to deliver real-time data for predictive maintenance.

Engineered with advanced eddy current technology, the BENTLY 330103-00-03-05-02-05 converts metallic target proximity into an electrical signal, supporting high-frequency response (0–10 kHz) for dynamic motion analysis. Its stainless-steel housing and self-shielded design resist corrosion, electromagnetic interference (EMI), and harsh environmental conditions, making it suitable for operation in temperatures ranging from -54°C to +177°C. The probe’s high sensitivity (7.87 V/mm) ensures accurate detection of minimal shaft movements, critical for early fault diagnosis in turbines, compressors, and generators.

In automation architectures, the BENTLY 330103-00-03-05-02-05 acts as a frontline sensor, providing real-time feedback on shaft position, eccentricity, and vibration amplitude. Its compatibility with BENTLY’s 3300 Series monitor modules (e.g., 3300/22M) enables seamless integration into comprehensive machinery protection systems, empowering engineers to optimize equipment reliability and reduce unplanned downtime.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 330103-00-03-05-02-05 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Eddy Current Proximity Probe |

| Probe Diameter | 5 mm |

| Cable Length | 3 m (PTFE-insulated) |

| Measurement Range | 0–2500 μm (linear) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | 0–10 kHz |

| Operating Temperature | -54°C to +177°C |

| Housing Material | Stainless steel |

| Connector Type | BENTLY 3300 Series compatible (male) |

| Weight | 0.35 kg |

| Certifications | CE, ISO 9001 |

Main Features and Advantages

High-Precision Eddy Current Sensing: The BENTLY 330103-00-03-05-02-05 utilizes eddy current principles to measure shaft displacement with micron-level accuracy, critical for detecting early signs of misalignment or bearing wear in rotating machinery. Its linear response ensures consistent performance across the entire measurement range.

Rugged Environmental Resistance: With a stainless-steel housing and PTFE-insulated cable, the probe withstands extreme temperatures, moisture, and EMI, making it suitable for harsh industrial environments. The self-shielded design minimizes cross-talk between adjacent probes, ensuring reliable measurements in dense installations.

Seamless System Integration: Designed for BENTLY’s 3300 Series, the BENTLY 330103-00-03-05-02-05 connects directly to monitor modules like the 3300/42M, enabling real-time data transmission and analysis. This integration streamlines system setup and reduces compatibility issues in complex automation architectures.

Wide Frequency Response: Capable of capturing dynamic movements up to 10 kHz, the probe is ideal for high-speed machinery, providing accurate feedback on shaft vibrations that could lead to failure if unaddressed. This feature supports predictive maintenance strategies in critical applications.

Long-Life Design: The probe’s corrosion-resistant materials and rugged construction ensure extended service life, even in demanding environments like offshore platforms or high-temperature manufacturing facilities, reducing maintenance costs and downtime.

Application Areas

The BENTLY 330103-00-03-05-02-05 is widely applied in industries requiring precise monitoring of rotating equipment:

-

Oil and Gas:

- Monitors compressor shafts in refineries and pipeline pumping stations to detect early signs of cavitation or bearing degradation, preventing unplanned shutdowns.

- Installed in offshore platforms to monitor drilling equipment under harsh marine conditions, ensuring safety and operational efficiency.

-

Power Generation:

- Measures shaft displacement in steam and gas turbines to optimize performance and prevent stator-rotor contact in power plants.

- Supports condition-based maintenance programs by providing real-time data on rotor dynamics, enabling scheduled repairs to minimize downtime.

-

Manufacturing:

- Controls vibration in high-speed packaging machinery and robotic arms, enhancing product quality and reducing production losses in automotive and pharmaceutical plants.

- Monitors motor bearings in conveyor systems to predict maintenance needs, improving overall equipment effectiveness (OEE).

-

Water/Wastewater Treatment:

- Ensures reliable operation of centrifugal pumps by detecting imbalance or misalignment, maintaining consistent water flow in treatment facilities.

- Integrates with SCADA systems for remote monitoring of pump stations, enabling proactive maintenance scheduling.

Related Products

- BENTLY 330103-00-05-10-02-00: A 5 mm probe with a longer 5 m cable, suitable for installations requiring greater distance from the monitor module.

- BENTLY 330102-00-05-10-02-00: A 5 mm probe with a different connector type, often used as an alternative for specific system configurations.

- BENTLY 330180-90-05: A proximity probe extension cable, compatible with the BENTLY 330103-00-03-05-02-05 to adjust installation depth in tight spaces.

- BENTLY 3300/22M 146031-01: A vibration monitoring module that processes signals from the BENTLY 330103-00-03-05-02-05 for comprehensive machinery health analysis.

- BENTLY 3300/42M 129408-01: A temperature/vibration monitor that pairs with the probe to provide multi-parameter equipment diagnostics.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 330103-00-03-05-02-05, ensure the following:

Before installing the BENTLY 330103-00-03-05-02-05, ensure the following:

- Verify the probe’s measurement range (0–2500 μm) matches the application and use BENTLY’s installation tools to set the initial gap (typically 1.5 mm) between the probe and target surface.

- Route the 3 m cable away from high-voltage lines to minimize EMI, securing it with stainless-steel clamps to prevent movement-induced damage.

- Ensure the operating temperature range (-54°C to +177°C) is compatible with the installation environment, using thermal insulation if necessary.

Maintenance Recommendations:

- Routine Inspections: Quarterly visual checks for cable abrasion, connector corrosion, and probe alignment, especially in high-vibration environments. Use a soft brush to clean debris from the probe tip.

- Calibration: Annual calibration using a BENTLY-certified vibration calibrator to ensure measurement accuracy. This involves applying known displacements and verifying output signals against standards.

- Environmental Monitoring: Regularly assess ambient conditions to ensure they remain within the probe’s operational limits, addressing any issues with ventilation or temperature control promptly.

- Spare Parts Management: Keep a spare BENTLY 330103-00-03-05-02-05 on hand for critical systems, as its hot-swappable design allows replacement without shutting down machinery.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 330103-00-03-05-02-05, covering hardware defects not caused by misuse or environmental damage. During the warranty period, we will replace any probe that fails to meet performance specifications. For discontinued models like the BENTLY 330103-00-03-05-02-05, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including calibration services and repair solutions, to maintain your equipment’s reliability throughout its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from BENTLY’s official specifications and industry applications. For detailed installation guidelines, refer to the BENTLY 330103-00-03-05-02-05 user manual or contact our technical support team for personalized assistance.

BENTLY 330876-03-50-00-00 S200

BENTLY 190065-00-01-03-01-01 Main frame

BENTLY 3500/54 133396-01 Control cabinet node unit

BENTLY 3500/92 136180-01 governor

BENTLY 3500/15 114M5330-01 Input module

BENTLY 3500/32 125712-01 Control processor

BENTLY 3500/42M 176449-02 Switch quantity input card

BENTLY 3500/54 133396-01 Control cabinet node unit

BENTLY 3500/92 136180-01 governor

BENTLY 3500/15 114M5330-01 Input module

BENTLY 3500/77M 176449-07 AI/AO/DI/DO module

BENTLY 3500/54 133396-01 Connecting module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: