Description

BENTLY 1900/27 Product Specification

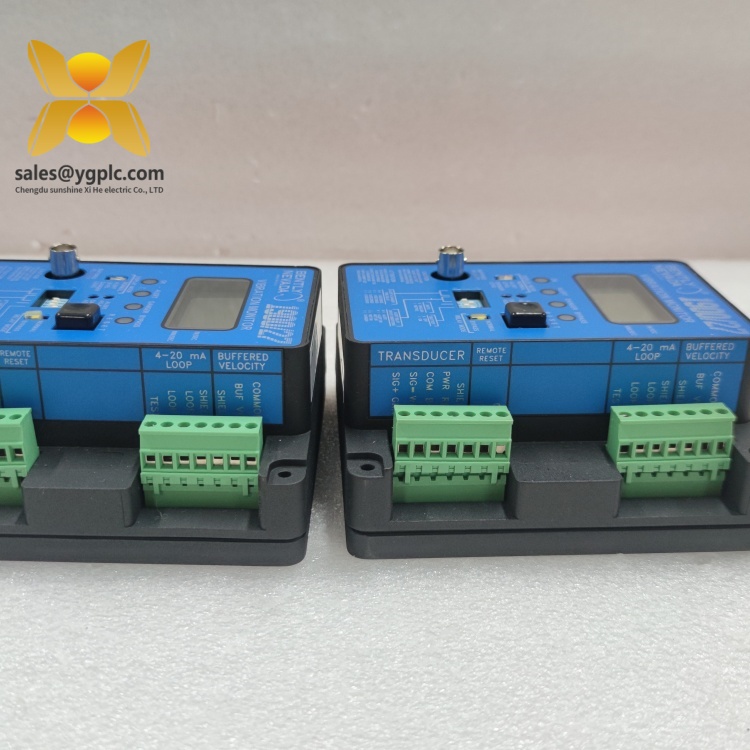

Product Overview

The BENTLY 1900/27 is a high-reliability vibration monitoring system designed for industrial machinery protection, specifically engineered as part of BENTLY’s 1900 Series of proximity probe systems. This compact and robust solution is tailored for continuous monitoring of shaft vibration, displacement, and eccentricity in rotating equipment, making it essential for industries such as power generation, oil and gas, and manufacturing. The BENTLY 1900/27 integrates advanced eddy current technology with user-friendly configuration, enabling real-time diagnostics to prevent costly equipment failures.

Featuring a 2-channel design, the BENTLY 1900/27 processes signals from proximity probes to provide precise measurements of shaft movement. Its modular architecture allows seamless integration with existing automation systems, while the rugged metal enclosure ensures reliable operation in harsh environments. The system supports a linear measurement range of 0–2500 μm and a frequency response up to 10 kHz, ensuring accurate capture of dynamic machinery behavior. As a cornerstone of predictive maintenance strategies, the BENTLY 1900/27 empowers engineers to monitor equipment health proactively, reducing downtime and extending asset lifespan.

In automation systems, the BENTLY 1900/27 acts as a frontline diagnostic tool, converting analog probe signals into digital data for analysis. Its self-shielded design minimizes electromagnetic interference, while the built-in alarm relay outputs enable immediate response to abnormal conditions. By combining high-precision sensing with durable construction, the BENTLY 1900/27 sets a standard for reliability in critical machinery monitoring applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 1900/27 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Vibration Monitoring System |

| Input Channels | 2 channels (proximity probes) |

| Measurement Range | 0–2500 μm (linear) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | 0–10 kHz |

| Power Supply | 100–240 VAC, 50/60 Hz |

| Physical Dimensions | 216 mm (W) × 140 mm (H) × 254 mm (D) |

| Weight | 3.2 kg |

| Operating Temperature | 0°C to +50°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL |

Main Features and Advantages

Dual-Channel Precision Sensing: The BENTLY 1900/27 supports two independent channels for simultaneous monitoring of multiple shaft positions, enabling comprehensive analysis of machinery dynamics. This feature is critical for detecting imbalances, misalignments, or bearing wear in complex systems like turbines and compressors.

Eddy Current Technology: Leveraging eddy current principles, the system delivers micron-level accuracy in displacement measurements, unaffected by dust, oil, or non-conductive contaminants. This ensures reliable performance in harsh industrial environments where other sensor types may fail.

Plug-and-Play Integration: The BENTLY 1900/27 integrates seamlessly with BENTLY’s 1900 Series probes and extension cables, reducing installation complexity. Its standardized interface also allows compatibility with third-party monitoring systems, enhancing flexibility in existing setups.

Real-Time Alarm Capability: Built-in alarm relays trigger immediate notifications for out-of-range conditions, enabling quick intervention to prevent equipment damage. The system’s LED indicators provide visual status updates, simplifying on-site diagnostics.

Rugged Industrial Design: Housed in a steel enclosure with EMI shielding, the BENTLY 1900/27 withstands vibration, temperature fluctuations, and electromagnetic interference, ensuring consistent performance in power plants, refineries, and manufacturing facilities.

Application Areas

The BENTLY 1900/27 is widely applied in industries requiring precise machinery health monitoring:

-

Power Generation:

- Monitors steam turbine shafts for displacement and vibration, preventing stator-rotor contact and optimizing energy production.

- Integrates with generator systems to ensure rotor alignment, reducing mechanical stress and extending equipment life.

-

Oil and Gas:

- Controls compressor shafts in refineries and pipeline pumping stations, detecting early signs of cavitation or bearing failure.

- Installed in offshore platforms to withstand harsh marine environments while monitoring drilling equipment.

-

Manufacturing:

- Monitors high-speed rotating machinery in automotive plants, such as engine test stands and conveyor drives.

- Ensures precision in paper mills by measuring roll displacement, improving product quality and reducing waste.

-

Water/Wastewater Treatment:

- Monitors pump shafts for imbalance or misalignment, maintaining consistent water flow in treatment facilities.

- Supports predictive maintenance in wastewater plants, minimizing downtime for critical pumping systems.

Related Products

- BENTLY 1900/20: A single-channel version of the BENTLY 1900/27, suitable for smaller setups requiring basic vibration monitoring.

- BENTLY 1900/30: A 4-channel system for complex machinery requiring multi-point monitoring, often used as an upgrade for the BENTLY 1900/27.

- BENTLY 7200 Proximity Probe: A compatible probe series designed for use with the BENTLY 1900/27, offering various diameters and cable lengths.

- BENTLY 1900/90 Power Supply: A redundant power module for the BENTLY 1900/27, ensuring uninterrupted operation in critical applications.

- BENTLY 1900/65 Communication Module: Enables Ethernet connectivity for the BENTLY 1900/27, supporting remote data access and cloud-based monitoring.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 1900/27, ensure the following:

Before installing the BENTLY 1900/27, ensure the following:

- Verify the power supply voltage (100–240 VAC) and ground the system to prevent electromagnetic interference. Use a multimeter to confirm stable voltage levels.

- Align the proximity probes with the target shaft surface, maintaining a nominal gap of 1.5 mm for optimal sensitivity. Refer to BENTLY’s installation guides for precise alignment specifications.

- Route probe cables away from high-voltage lines to minimize interference, securing them with stainless-steel clamps to prevent movement-induced damage.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for alarms) and cleaning of dust from ventilation slots.

- Calibration: Annual calibration using a BENTLY-certified vibration calibrator to ensure measurement accuracy. This involves applying known displacement values and verifying output signals.

- Cable Integrity Checks: Biannual inspection of probe and extension cables for abrasion or connector degradation, replacing damaged components promptly.

- Firmware Updates: Periodically update the system firmware via BENTLY’s software to access new diagnostic features and compatibility improvements.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 1900/27, covering hardware failures due to non-human factors. During the warranty period, we will replace any system that exhibits abnormal performance or functional defects. For discontinued models like the BENTLY 1900/27, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including calibration services and repair solutions, to maintain your equipment’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from BENTLY’s official specifications and industry applications. For detailed installation guidelines, refer to the BENTLY 1900/27 user manual or contact our technical support team.

BENTLY 125768-01 ACS880

BENTLY 125800-01 System

BENTLY 126632-01 DCS

BENTLY 128031-01 Network communication module

BENTLY 128085-01 Board interface module

BENTLY 128277-01 Fault-tolerant board

BENTLY 131151-01 Power module

BENTLY 132417-01 Cable/terminal/Matching

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: