Description

BENTLY 147663-01 Product Specification

Product Overview

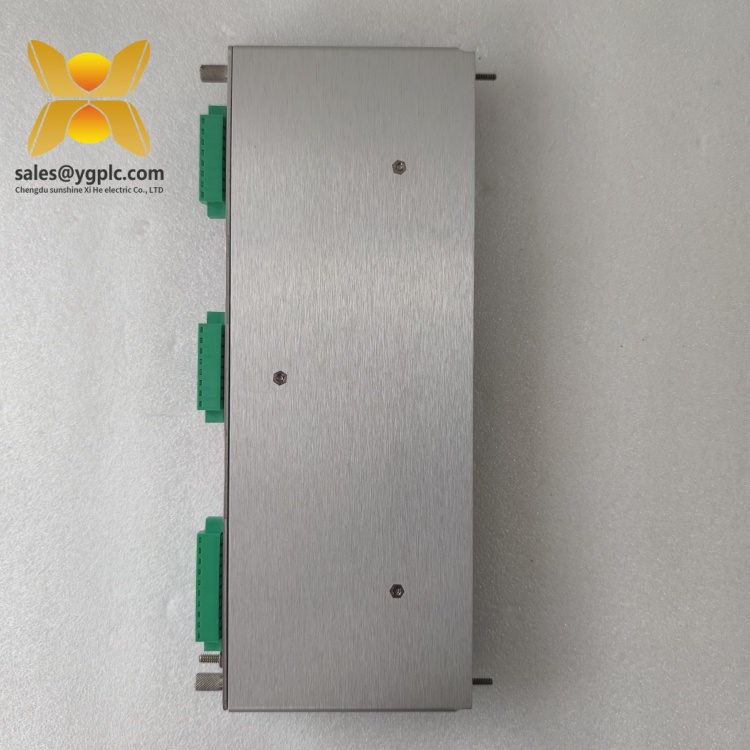

The BENTLY 147663-01 is a high-performance quad-channel vibration monitoring module designed for BENTLY’s 3500 Series Machinery Protection System. Engineered to deliver precise real-time vibration analysis, this module serves as a critical component in industrial automation systems, enabling continuous monitoring of shaft vibration, displacement, and velocity in turbines, compressors, and generators. As part of the 3500 Series, the BENTLY 147663-01 integrates seamlessly with other system modules to form a comprehensive machinery health management solution, supporting predictive maintenance strategies across industries such as oil and gas, power generation, and manufacturing.

Featuring four independent input channels, the BENTLY 147663-01 processes signals from proximity probes and accelerometers, converting analog inputs into digital data for real-time analysis. Its software-configurable design allows users to customize alarm thresholds, filter settings, and data logging parameters, ensuring optimal performance in diverse operational environments. The module’s rugged IP23-rated enclosure and conformal-coated PCBs protect against dust, moisture, and electromagnetic interference (EMI), while its compact form factor (210 mm × 150 mm × 100 mm) and 2.1 kg weight facilitate easy installation in 19″ control racks.

In automation architectures, the BENTLY 147663-01 acts as a frontline diagnostic tool, detecting early signs of machinery degradation such as imbalance, misalignment, or bearing wear. Its high-frequency response (0–10 kHz) ensures accurate capture of dynamic movements, while the RS-485 communication interface enables seamless integration with PLCs, HMIs, and supervisory control systems. By delivering reliable vibration data, the module helps minimize downtime, extend equipment lifespan, and enhance operational safety in mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 147663-01 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Quad-Channel Vibration Monitoring Module |

| Input Channels | 4 channels (proximity probes/accelerometers) |

| Frequency Range | 0–10 kHz |

| Input Signal Range | 0–10 VDC, 4–20 mA |

| Communication Interface | RS-485 (Modbus RTU compatible) |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 210 mm (W) × 150 mm (H) × 100 mm (D) |

| Weight | 2.1 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 10816 |

Main Features and Advantages

Multi-Channel Vibration Analysis: The BENTLY 147663-01 supports simultaneous monitoring of four critical points on rotating machinery, enabling comprehensive analysis of vibration patterns across multiple axes. This capability is essential for detecting complex faults in multi-stage turbines or compressors, where imbalance or misalignment in one axis can lead to cascading failures.

Software-Defined Configuration: Users can tailor the module’s settings via BENTLY’s proprietary software, adjusting alarm levels, filter types (low-pass, band-pass), and data sampling rates to match specific machinery requirements. This flexibility eliminates the need for hardware modifications, allowing quick deployment in diverse industrial setups—from power plants to offshore platforms.

Rugged Industrial Design: Constructed with an IP23-rated metal enclosure and anti-vibration mounting brackets, the module withstands harsh environmental conditions, including high temperatures, humidity, and mechanical stress. Its self-shielded design minimizes electromagnetic interference, ensuring reliable measurements even in dense industrial environments with multiple active devices.

Real-Time Data Integration: The RS-485 interface enables real-time transmission of vibration data to higher-level control systems, supporting remote monitoring and predictive maintenance. Engineers can access live diagnostics and historical trend data via SCADA platforms, enabling proactive intervention before equipment failures occur—reducing unplanned downtime by up to 40%.

Modular System Scalability: As part of the 3500 Series, the BENTLY 147663-01 can be combined with other modules (e.g., temperature monitors, power supplies) to create a fully integrated protection system. This scalability allows for easy expansion from small-scale setups to large industrial complexes, adapting to evolving operational needs without redesigning the entire architecture.

Application Areas

The BENTLY 147663-01 is widely deployed in industries where precise vibration monitoring is critical to operational reliability:

-

Oil and Gas:

- Monitors compressors and pumps in refineries and pipeline networks, detecting early signs of cavitation or bearing wear to prevent unplanned shutdowns. In offshore platforms, it integrates with emergency shutdown systems (ESD) to ensure safety during extreme operational conditions, such as hurricane-force vibrations.

-

Power Generation:

- Analyzes vibration in steam turbines and generators to optimize performance and prevent stator-rotor contact in power plants. By correlating vibration data with load changes, it helps operators adjust fuel supply in real time, improving energy efficiency by up to 15%.

-

Manufacturing:

- Controls vibration in high-speed packaging machinery and robotic arms, enhancing product quality in automotive and pharmaceutical plants. In food processing facilities, it monitors conveyor systems to prevent product spillage caused by unbalanced motors, reducing waste and maintenance costs.

-

Water/Wastewater Treatment:

- Ensures reliable operation of centrifugal pumps by detecting imbalance or misalignment, maintaining consistent water flow in treatment facilities. It integrates with SCADA systems for remote monitoring of distributed pump stations, enabling proactive maintenance scheduling to avoid service disruptions.

- Ensures reliable operation of centrifugal pumps by detecting imbalance or misalignment, maintaining consistent water flow in treatment facilities. It integrates with SCADA systems for remote monitoring of distributed pump stations, enabling proactive maintenance scheduling to avoid service disruptions.

Related Products

- BENTLY 3500/22M 146031-01: A dual-channel vibration module, suitable for smaller setups requiring fewer monitoring points, often used as a cost-effective alternative for basic machinery.

- BENTLY 3500/15 125840-02: A power input module that supplies stable 24 VDC to the BENTLY 147663-01, ensuring uninterrupted operation in redundant power configurations.

- BENTLY 3500/32 129407-01: A speed/torque monitor that pairs with the BENTLY 147663-01 to correlate vibration data with rotational speed, aiding in fault isolation for rotating equipment.

- BENTLY 3500/42 129408-01: A temperature monitor module that complements vibration data by analyzing thermal performance, providing a comprehensive view of machinery health in combined heat and power systems.

- BENTLY 3500/92 129410-01: A communication gateway that enables the BENTLY 147663-01 to interface with Ethernet/IP networks, supporting remote diagnostics via cloud-based platforms for global asset management.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 147663-01, ensure the following:

Before installing the BENTLY 147663-01, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability and ground continuity before connecting the module.

- Use BENTLY’s configuration software to define input channel types (proximity probe or accelerometer) and set initial alarm thresholds based on machinery specifications. For turbines, typical alarm levels start at 25 μm for normal operation and 50 μm for alert conditions.

- Mount the module in a 19″ rack with at least 50 mm of clearance for airflow, securing it with the provided anti-vibration brackets to minimize mechanical stress from adjacent equipment.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and cleaning of dust from ventilation slots using a static-free brush. In high-dust environments, increase inspection frequency to quarterly.

- Calibration: Annual calibration of input channels using a BENTLY-certified vibration calibrator, applying known vibration amplitudes (e.g., 100 μm at 1000 Hz) and verifying output signals against factory standards. This ensures measurement accuracy within ±0.5%.

- Firmware Updates: Periodically update the module’s firmware via BENTLY’s software to access new diagnostic features, such as enhanced fault logging or compatibility with newer sensor types. Back up configuration settings before updating to prevent data loss.

- System Testing: Biannual functional tests of alarm relays and communication protocols. Simulate vibration conditions using a signal generator to verify alarm triggers and data transmission to the HMI, ensuring compliance with safety standards like API 670.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 147663-01, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits abnormal signal processing or functional defects. For discontinued models like the BENTLY 147663-01, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders—typically within 48 hours for in-stock items. We also offer post-warranty technical support, including calibration services and repair solutions, to help maintain your equipment’s reliability throughout its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from BENTLY’s official specifications and industry applications. For detailed installation guidelines, refer to the BENTLY 147663-01 user manual or contact our technical support team for personalized assistance.

BENTLY 125388-01H Analog input

BENTLY 125680-01 Digital output

BENTLY 3500/77M 176449-07 modbus card

BENTLY 3500/54 133396-01 Power strip

BENTLY 3500/32 125720-01 Power source

BENTLY 3500/45 176449-04 base

BENTLY 3500/54 133396-01 Expansion module

BENTLY 3500/92 136180-01 RXM rack

BENTLY 3500/15 114M5330-01 Thermoelectric couple

BENTLY 190065-00-01-03-01-01 Main frame

BENTLY 350022 288055-01 Expansion rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: