Description

TRICONEX 3000510-380 Product Specification

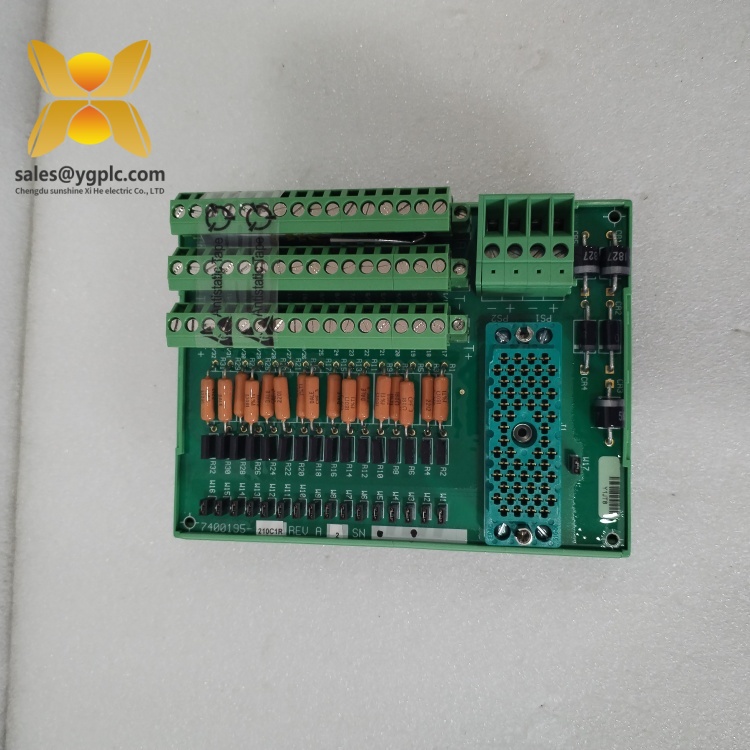

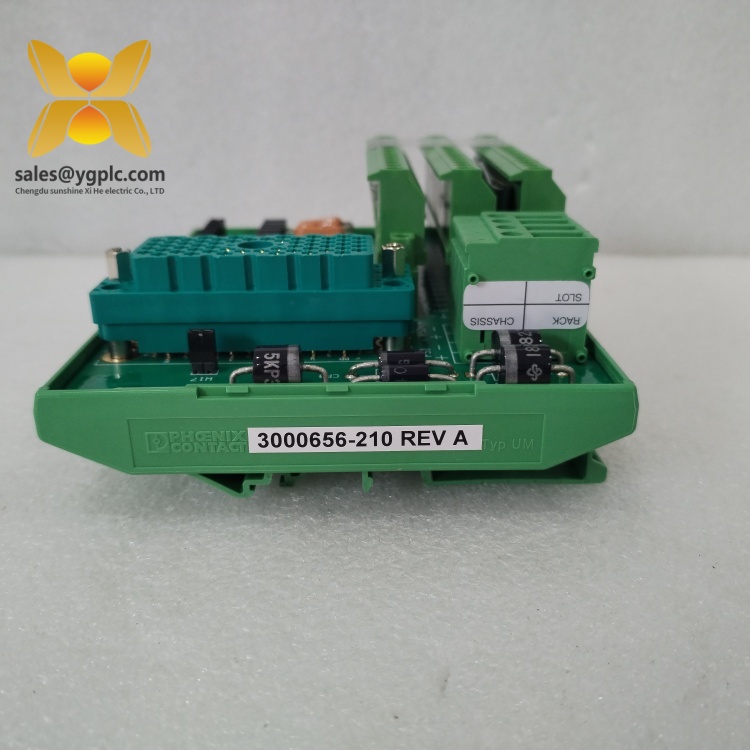

Product Overview

The TRICONEX 3000510-380 is a high-reliability industrial controller interface module designed for TRICONEX’s Triple Modular Redundant (TMR) safety instrumented systems (SIS). Engineered to deliver fail-safe control in critical industrial processes, this module serves as a bridge between the system’s logic solver and field devices, ensuring seamless integration and real-time data exchange. As part of TRICONEX’s TMR platform, the 3000510-380 ensures continuous operation even in harsh environments, making it essential for applications where downtime risks catastrophic consequences, such as oil refineries, chemical plants, and nuclear power facilities .

Featuring a Triple Modular Redundant (TMR) architecture, the 3000510-380 uses three independent processing channels to eliminate single points of failure. This design ensures fault tolerance, with automatic detection and isolation of malfunctions, allowing the system to continue operating safely even if one channel fails. The module supports Ethernet and PROFIBUS DP communication protocols, enabling fast and reliable data exchange with distributed I/O modules, PLCs, and other control system components .

Built to withstand extreme conditions, the 3000510-380 operates reliably between -40°C and +70°C and supports humidity levels up to 95% non-condensing. Its compact design (19-inch rack mountable) and lightweight construction facilitate easy installation in standard control cabinets, while its hot-swappable design enables maintenance without system downtime. Certified to meet SIL 2 standards (IEC 61508), the 3000510-380 ensures compliance with global regulations for risk mitigation in process industries .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TRICONEX 3000510-380 |

| Manufacturer | TRICONEX |

| Product Type | Industrial Controller Interface Module (TMR Architecture) |

| Compatible Systems | TRICONEX TMR Safety Instrumented Systems (SIS), including Trident and Tri-GP platforms |

| Communication Protocols | Ethernet, PROFIBUS DP |

| Redundancy | Triple Modular Redundant (TMR) with automatic fault detection and isolation |

| Physical Dimensions | 19-inch rack mountable (standard form factor) |

| Weight | N/A (lightweight design for easy installation) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing, no frost |

| Certifications | SIL 2 (IEC 61508), CE, UL 508 |

| Input Voltage | 24 VDC (from redundant power supplies like TRICONEX 3700A) |

| I/O Channels | 32 channels (programmable for analog/digital input/output) |

| Environmental Rating | NEMA 4, IP66 (dust and water ingress protection) |

3000510-380

Related Products

- TRICONEX 3700A: A redundant power supply module that provides 24 VDC input to the 3000510-380, ensuring stable power distribution .

- TRICONEX 3008: A TMR main processor module that sends control signals to the 3000510-380 for executing safety logic in critical processes .

- TRICONEX 3721: A digital input module that works alongside the 3000510-380 to monitor emergency stop signals and interlocks .

- TRICONEX 4351B: An analog output module that complements the 3000510-380 in hybrid control systems requiring both discrete and continuous outputs .

- TRICONEX 2201: A communication baseplate that integrates the 3000510-380 into the TMR rack, facilitating backplane communication .

Main Features and Advantages

Triple Modular Redundancy (TMR): The 3000510-380 employs three independent processing channels, each with its own power supply and logic circuits. If one channel fails, the other two continue operation, ensuring zero interruption to critical outputs. This architecture is vital in nuclear power plants, where a single channel failure could disable reactor cooling systems .

SIL 2 Compliance: Designed to meet IEC 61508 SIL 2 standards, the 3000510-380 minimizes the probability of dangerous failures, making it suitable for applications with moderate to high risk exposure, such as offshore platform ESD systems .

Harsh Environment Resilience: With an operating temperature range of -40°C to +70°C and IP66 protection against dust and water ingress, the 3000510-380 performs reliably in extreme conditions, including desert oil fields and arctic LNG terminals .

Flexible Communication: Supports Ethernet and PROFIBUS DP protocols, enabling seamless integration with diverse control systems and field devices. This flexibility is critical in chemical processing plants, where valves and pumps from multiple vendors require varied control signals .

Hot-Swap Capability: The 3000510-380 can be replaced while the system remains operational, reducing maintenance downtime by up to 90% compared to non-hot-swappable modules. This feature is essential in continuous-process industries like pharmaceuticals, where production halts are costly .

3000510-380

Installation and Maintenance

Pre-installation Preparations: Before installing the 3000510-380, verify the input voltage (24 VDC) from a compatible power supply (e.g., TRICONEX 3700A). Clean the rack slot and ensure proper alignment with the backplane connectors. Secure the module using captive screws and tighten all terminal block connections to prevent loose contacts .

Maintenance Suggestions: Inspect the 3000510-380 monthly for signs of overheating, corrosion, or physical damage. Use a dry cloth to remove dust from the module’s surface and vents. Quarterly, simulate a channel fault using TRICONEX’s diagnostic tools to verify redundancy functionality. If fault indicators persist, replace the module promptly to avoid cascading failures .

Application Fields

Oil and Gas: The 3000510-380 controls emergency shutdown valves in offshore platforms, ensuring rapid isolation of leaks or equipment failures. Its TMR architecture prevents false trips during storms or power surges, maintaining operational continuity .

Chemical Processing: In batch reactors, the module actuates isolation valves based on temperature and pressure inputs from TRICONEX 3721 digital input modules. This ensures safe containment of hazardous chemicals during process upsets .

Nuclear Power: Used in reactor protection systems, the 3000510-380 energizes coolant pumps and containment isolation systems. Its SIL 2 certification and TMR design meet nuclear industry requirements for fail-safe operation .

Water Treatment: In wastewater treatment plants, the module controls pump motors and disinfection systems, ensuring compliance with environmental regulations. Its wide temperature range supports outdoor installations in harsh climates .

3000510-380

Product Guarantee

Our company offers a one-year quality warranty service for the TRICONEX 3000510-380, covering hardware malfunctions unrelated to human error. During the warranty period, we provide free replacement for modules exhibiting abnormal performance, such as output inconsistencies or communication failures. For urgent or discontinued models, our global supply chain network ensures rapid delivery of scarce spare parts, minimizing downtime for critical systems. Established in 2007, we specialize in distributing industrial control components, including hard-to-find TRICONEX modules, with a large inventory and competitive pricing to meet customers’ immediate needs.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

This product description is generated based on publicly available technical data and industry best practices. For detailed specifications, refer to TRICONEX’s official documentation.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: