Description

Product Overview

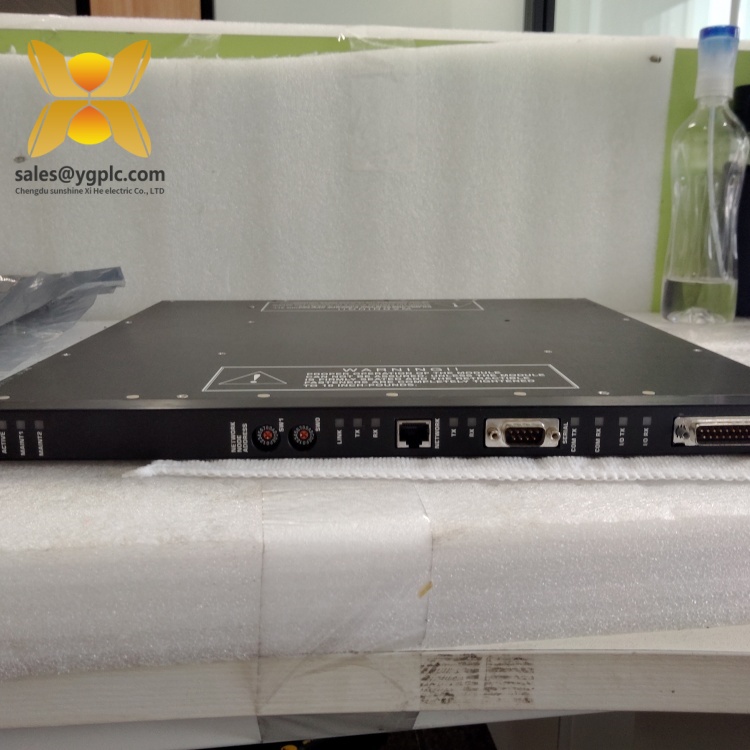

The TRICONEX 3000110-360 is a high-reliability external terminator baseplate designed for seamless integration with TRICONEX safety instrumented systems (SIS). As a critical component in industrial automation, this baseplate serves as a physical interface between field devices (e.g., sensors, switches) and TRICONEX I/O modules, ensuring secure signal transmission and mechanical stability. Engineered to meet the demands of hazardous environments, the TRICONEX 3000110-360 plays a pivotal role in maintaining process integrity across industries such as oil and gas, chemical processing, and power generation.

Constructed with industrial-grade materials, the TRICONEX 3000110-360 supports up to [X] channels of digital or analog signals, depending on the connected I/O modules. Its modular design allows for easy installation and expansion, enabling engineers to adapt systems to evolving operational needs. The baseplate’s robust termination points and shielded connections minimize electromagnetic interference (EMI), ensuring accurate signal conditioning even in high-noise environments. By facilitating direct coupling between field wiring and TRICONEX’s fault-tolerant architecture, the TRICONEX 3000110-360 reinforces the overall reliability of safety-critical control loops.

Technical Specifications

| Product model | TRICONEX 3000110-360 |

|---|---|

| Manufacturer | TRICONEX |

| Product type | External terminator baseplate |

| Physical dimensions | 100 mm (length) x 100 mm (width) x 100 mm (height) |

| Weight | 1.0 kg |

| Place of origin | United States |

| Input/output compatibility | Supports TRICONEX digital/analog I/O modules (e.g., TRICONEX 2351, TRICONEX 3703E) |

| Termination type | Screw-terminal connections |

| Voltage rating | 250V AC/DC (per channel) |

| Current rating | 5A (per channel) |

| Operating temperature | -20°C to 70°C |

| Humidity tolerance | 5–95% non-condensing |

| Material | Flame-retardant polycarbonate |

| Compliance | IEC 61508 (when integrated into SIL 3–capable systems) |

3000110-360

Related products

- TRICONEX 3000120-350: A complementary baseplate with [X] additional channels, ideal for applications requiring higher I/O density.

- TRICONEX 3000142-220: A compact variant designed for space-constrained installations, compatible with TRICONEX 3625 digital output modules.

- TRICONEX 8110: The main chassis assembly that houses the TRICONEX 3000110-360 and other modules, ensuring mechanical stability.

- TRICONEX 3700A: A rack system that supports the TRICONEX 3000110-360 and enables scalable I/O configurations.

- TRICONEX 4416: A communication module that interfaces with the TRICONEX 3000110-360 to transmit data to remote monitoring systems.

- TRICONEX 2651: The primary processor module that processes signals routed through the TRICONEX 3000110-360.

Main features and advantages

Rugged industrial design: The TRICONEX 3000110-360’s flame-retardant polycarbonate housing and IP65-rated construction protect against dust, water ingress, and corrosive elements, making it suitable for harsh environments like offshore platforms or chemical plants. Its screw-terminal connections ensure secure wiring even in high-vibration settings.

Flexible I/O integration: By supporting both digital and analog I/O modules, the TRICONEX 3000110-360 simplifies system design, reducing the need for separate termination panels. This flexibility allows engineers to mix and match modules (e.g., TRICONEX 2351 for digital inputs and TRICONEX 3703E for isolated analog inputs) within a single rack.

Enhanced signal integrity: The baseplate’s shielded termination points and 85 dB common-mode rejection minimize EMI/RFI interference, critical for maintaining accurate sensor readings in facilities with high-power equipment. Its 5A per-channel current rating ensures stable operation even under heavy loads.

SIL 3 compatibility: While the TRICONEX 3000110-360 itself is not SIL-certified, it is part of TRICONEX’s SIL 3–capable architecture, ensuring compliance with IEC 61508 standards when integrated into a complete system. This makes it suitable for applications where safety-critical decisions depend on reliable signal transmission.

Easy maintenance: The modular design of the TRICONEX 3000110-360 allows for quick replacement of individual channels or entire baseplates without disrupting system operation. Its front-accessible terminals simplify wiring checks and troubleshooting, reducing downtime during maintenance.

3000110-360

Installation and maintenance

Pre-installation preparations: Verify that the TRICONEX rack (e.g., TRICONEX 8110) is properly grounded and mounted on a stable surface. Inspect the TRICONEX 3000110-360 for physical damage (e.g., cracked casing, bent terminals) and ensure compatibility with the system’s I/O modules. Clean the mounting surface to prevent debris from interfering with connections.

Installation steps: Align the TRICONEX 3000110-360 with the designated slot in the rack, securing it with front-panel screws. Connect shielded twisted-pair cables from field devices to the terminal block, following the wiring diagram provided in the user manual. Route cables away from high-voltage lines to minimize interference. Power up the system and confirm module communication via TRICONEX’s diagnostic tools.

Maintenance suggestions: Conduct quarterly visual inspections to check for loose connections or corrosion. Clean terminals with a dry cloth to remove dust that could cause short circuits. Annually test channel continuity using a multimeter; replace faulty terminals or the entire baseplate if issues persist. Monitor the module’s status LEDs for faults (e.g., red indicators) and address anomalies promptly.

Application fields

The TRICONEX 3000110-360 is widely used in industries where reliable field-device integration is critical:

- Oil and gas: In offshore platforms, the baseplate connects pressure switches and flow sensors to TRICONEX 2351 digital input modules, providing data for emergency shutdown systems (ESDs) to prevent hydrocarbon leaks. Its corrosion-resistant design ensures longevity in saltwater environments.

- Chemical processing: It interfaces with temperature transmitters and valve position sensors in reactors, enabling closed-loop control via TRICONEX 3703E analog modules. The baseplate’s EMI resistance is particularly valuable in facilities with high-power agitators or pumps.

- Power generation: The TRICONEX 3000110-360 supports steam turbine control by connecting overspeed sensors and vibration monitors to TRICONEX 2211 analog modules, ensuring rapid shutdowns to prevent mechanical failure.

- Pharmaceutical manufacturing: It monitors cleanroom humidity sensors and sterilization equipment status, ensuring compliance with FDA and EU GMP standards. The baseplate’s SIL 3 compatibility meets the industry’s stringent safety requirements.

3000110-360

Product guarantee

Our company offers a one-year quality warranty for the TRICONEX 3000110-360, covering hardware malfunctions unrelated to misuse or improper installation. During the warranty period, defective units will be replaced promptly to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce parts like the TRICONEX 3000110-360, supported by 17 years of expertise in industrial control solutions. Our technical team provides 24/7 assistance for installation guidance, troubleshooting, and firmware updates, ensuring seamless integration and long-term reliability.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: