Description

TRICONEX 2281 Product Specification

Product Overview

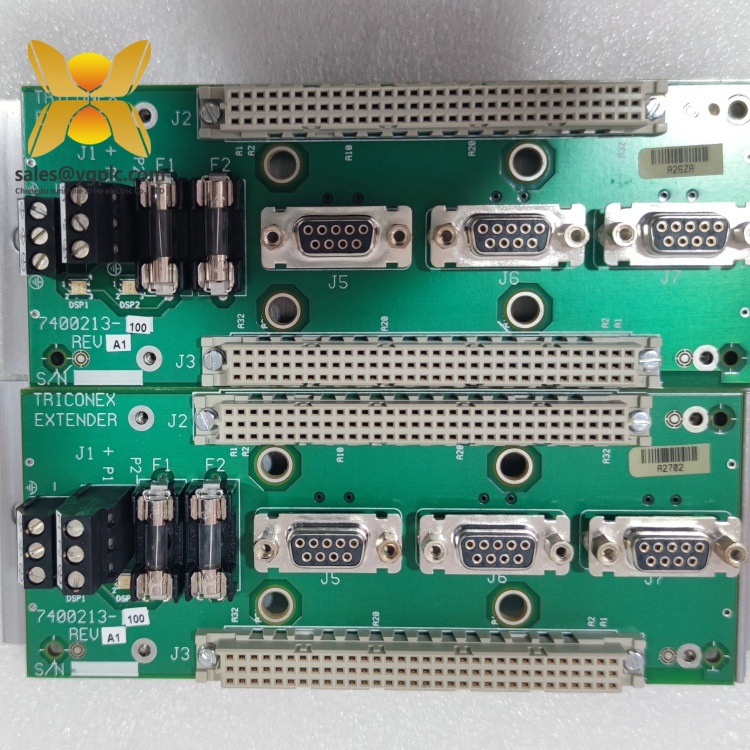

The TRICONEX 2281 is a high-reliability Trident Extender Bus Assembly Kit designed for TRICONEX’s Triple Modular Redundant (TMR) safety instrumented systems (SIS). It serves as a critical component for expanding communication capabilities between the main controller and distributed I/O modules, enabling seamless integration of field devices across large industrial facilities. By extending the communication bus up to 1,000 meters, the TRICONEX 2281 ensures real-time data exchange and control in applications where physical separation of components is necessary, such as offshore platforms or chemical plants with sprawling layouts .

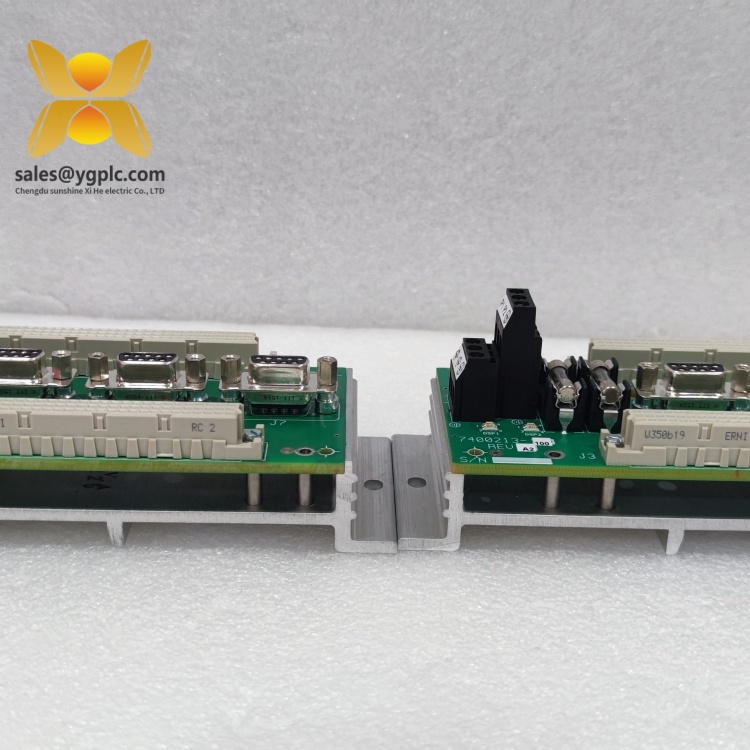

As part of TRICONEX’s Trident platform, the TRICONEX 2281 includes two extender boards and interface cables that connect to the I/O columns of the Trident system. This configuration allows the main controller to communicate with additional I/O modules located far from the central rack, maintaining system integrity and responsiveness. The kit’s triple modular redundant (TMR) architecture ensures that even if one communication path fails, the other two continue to operate, preventing disruptions in safety-critical processes like emergency shutdowns .

Built to withstand harsh industrial environments, the TRICONEX 2281 operates in temperatures from -40°C to +85°C and features an IP66-rated enclosure, protecting against dust, water, and electromagnetic interference. Its compact design (229 mm × 178 mm × 64 mm) and lightweight structure (3.2 kg) facilitate easy installation in standard control cabinets, while the modular design supports hot-swappable components for minimal downtime during maintenance .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TRICONEX 2281 |

| Manufacturer | TRICONEX |

| Product Type | Trident Extender Bus Assembly Kit |

| Compatible Systems | TRICONEX Trident TMR Safety Instrumented Systems (SIS) |

| Communication Range | Up to 1,000 meters between main controller and I/O modules |

| Input Voltage | 24 VDC (from redundant power supplies like TRICONEX 3700A) |

| Communication Protocols | RS-232, RS-485, Ethernet (EtherCAT) |

| Physical Dimensions | 229 mm (L) × 178 mm (W) × 64 mm (H) [9.02″ × 7.01″ × 2.52″] |

| Weight | 3.2 kg (7.05 lb) |

| Operating Temperature | -40°C to +85°C |

| Environmental Rating | IP66 (dust and water ingress protection) |

| Redundancy | Triple modular redundant (3 independent communication paths) |

| Certifications | CE, UL 508, IEC 61508 (SIL 3 compliant) |

2281

Related Products

- TRICONEX 3700A: A redundant power supply module that provides 24 VDC to the TRICONEX 2281, ensuring stable operation of the extender bus .

- TRICONEX 3008: A TMR main processor module that communicates with the TRICONEX 2281 to control distributed I/O modules in critical processes .

- TRICONEX 2201: A communication baseplate that connects the TRICONEX 2281 to the Trident system’s backplane, enabling data flow between modules .

- TRICONEX 3721: A digital input module that works with the TRICONEX 2281 to monitor emergency stop signals in remote locations .

- TRICONEX 4351B: An analog output module that complements the TRICONEX 2281 by handling variable outputs (e.g., valve positioning) in extended I/O setups .

Main Features and Advantages

Long-distance communication: The TRICONEX 2281 extends the Trident system’s communication bus up to 1,000 meters, allowing I/O modules to be placed far from the main controller. This is crucial in large industrial sites like oil refineries, where field devices are spread across vast areas. The extender bus ensures real-time data exchange, preventing delays in safety actions such as pipeline shutdowns .

Triple modular redundancy: With three independent communication paths, the TRICONEX 2281 ensures continuous operation even if one path fails. Each path processes data separately, and the system automatically switches to the remaining functional paths. This redundancy minimizes the risk of communication failures in nuclear power plants or chemical processing facilities, where downtime could have catastrophic consequences .

SIL 3 compliance: Designed to meet IEC 61508 SIL 3 standards, the TRICONEX 2281 guarantees high-integrity communication in safety-critical applications. It reduces the likelihood of spurious signals or data corruption, ensuring that emergency shutdown commands are executed accurately and promptly .

Rugged environmental performance: The TRICONEX 2281’s IP66-rated enclosure protects against dust, water jets, and extreme temperatures (-40°C to +85°C). This makes it suitable for outdoor installations like offshore platforms or desert oil fields, where conventional communication systems might fail due to harsh conditions .

Easy integration and scalability: The TRICONEX 2281 seamlessly integrates with Trident system racks and backplanes, requiring no additional wiring or configuration tools. Its modular design allows for easy expansion of I/O modules as plant operations grow, reducing the need for costly system overhauls .

2281

Installation and Maintenance

Pre-installation preparations: Before installing the TRICONEX 2281, power off the Trident rack and verify the input voltage (24 VDC) from a compatible power supply. Clean the rack slots and ensure proper alignment of the extender boards. Connect the interface cables between the main controller and remote I/O modules, tightening all connections to prevent signal loss. Use shielded cables to minimize electromagnetic interference in high-noise environments .

Maintenance suggestions: Inspect the TRICONEX 2281 monthly for loose cables, signs of corrosion, or overheating. Clean dust from the enclosure using a dry cloth and check the IP66 seals for damage. Quarterly, test communication integrity by simulating a fault in one path to ensure the system switches to redundant paths without disruption. If diagnostic LEDs indicate a persistent fault, replace the affected extender board or cable to maintain system reliability .

Application Fields

In oil and gas: The TRICONEX 2281 extends communication to emergency shutdown valves and pressure sensors on offshore platforms, ensuring rapid response to leaks or equipment failures. Its long-range capability allows central control rooms to monitor and actuate devices across kilometers of pipelines .

In chemical processing: Used in distributed control systems for batch reactors, the TRICONEX 2281 connects temperature and pressure transmitters to the main controller. This enables real-time adjustments and shutdowns to prevent overpressure or chemical spills in large-scale production facilities .

In nuclear power: The TRICONEX 2281 facilitates communication between reactor control modules and remote cooling systems. Its SIL 3 compliance and redundancy ensure uninterrupted operation, critical for maintaining safe reactor temperatures during normal and emergency conditions .

In water treatment: Installed in pump stations, the TRICONEX 2281 links level sensors and motor controllers to a central SIS. This allows coordinated shutdowns and alarms in flood-prone areas, protecting infrastructure from damage .

2281

Product Guarantee

Our company offers a one-year quality warranty service for TRICONEX 2281, covering hardware malfunctions not caused by human factors. During the warranty period, if TRICONEX 2281 shows abnormal performance—such as communication 中断 or signal degradation—we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

Established in 2007, our company is a leading import-export trade distributor specializing in industrial control spare parts, including hard-to-find and discontinued models. With a vast inventory and efficient supply channels, we ensure rapid delivery to meet customers’ urgent requirements for TRICONEX and other major brands like ABB, GE, and BENTLY NEVADA.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: