Description

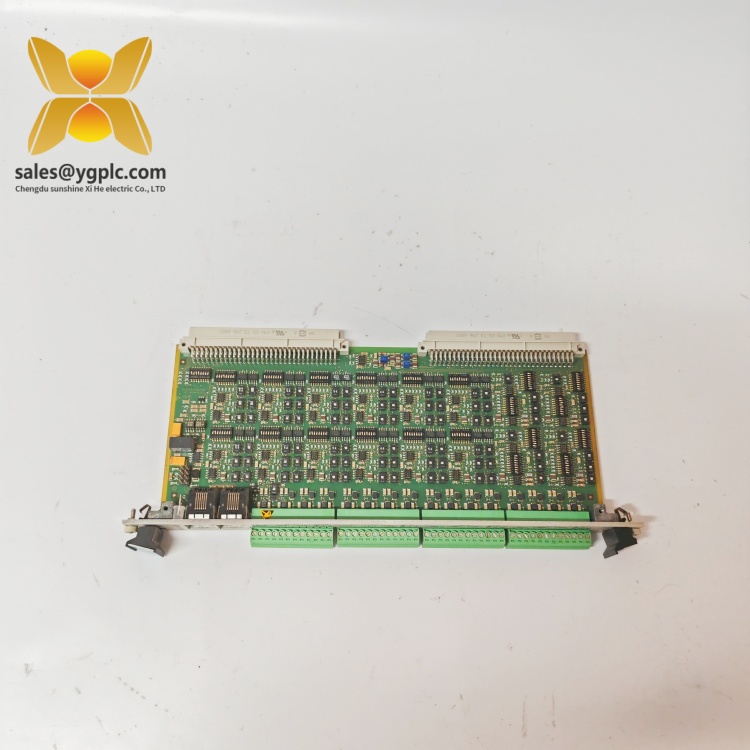

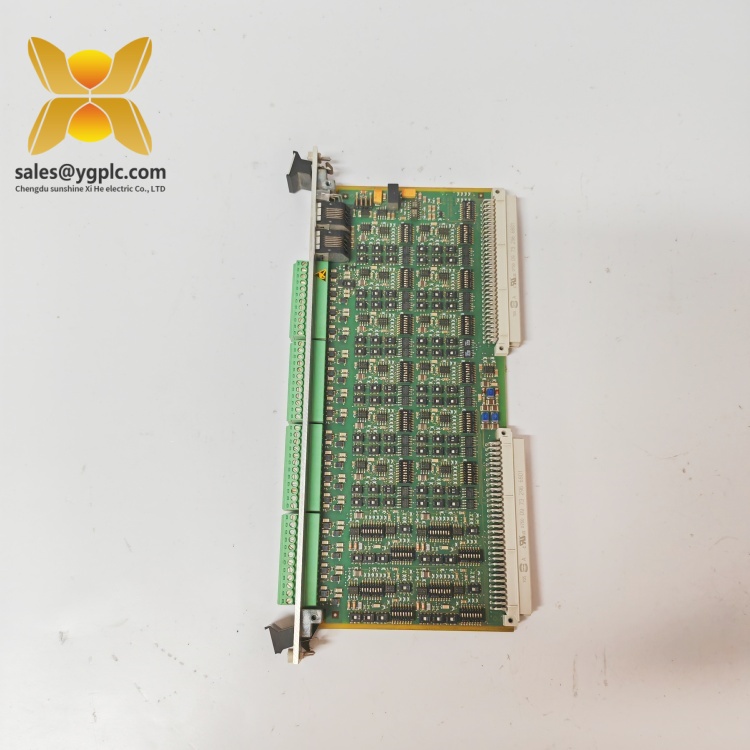

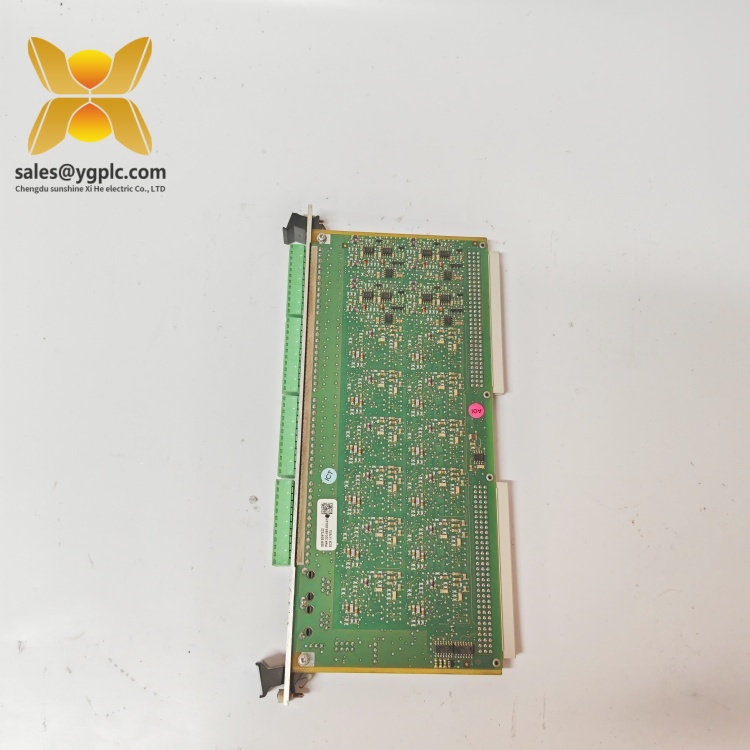

VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 Intelligent Output/Input Controller

Product Overview :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

The VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 intelligent output/input controller is a high-performance industrial monitoring solution designed for precise vibration and process parameter measurement in critical rotating machinery. As a core component of VIBRO-METER’s VM600 Series, this controller acts as a central hub for data acquisition, processing, and transmission, enabling real-time health monitoring of turbines, compressors, and generators in demanding industrial environments.

Engineered for reliability, the VM600 IOC16T features 16 configurable input/output channels that accept signals from accelerometers, proximity probes, and thermocouples, converting them into actionable data for predictive maintenance. Its dual-core processor ensures rapid data processing and supports advanced algorithms for vibration analysis, including spectrum analysis and trend monitoring. The controller’s modular design allows seamless integration with the VM600 Rack System, a scalable platform that adapts to both simple machinery setups and complex multi-unit installations.

In automation systems, the VM600 IOC16T bridges the gap between field sensors and control systems, providing accurate measurements critical for preventing catastrophic failures. Its wide operating temperature range (-40°C to +70°C) and IP65 protection rating make it suitable for harsh environments, while Modbus TCP/IP and Profibus DP communication protocols ensure compatibility with existing SCADA, DCS, and PLC networks. By delivering real-time insights into machinery health, this controller empowers operators to optimize maintenance schedules, reduce downtime, and enhance overall system reliability.

Technical Specifications :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VM600 IOC16T 200-565-000-013 200-565-101-013 |

| Manufacturer | VIBRO-METER |

| Product Type | Intelligent I/O Controller for Vibration Monitoring |

| Input Channels | 16 (8 dynamic vibration, 8 static process) |

| Input Types | Accelerometer (IEPE), proximity probe (DC), thermocouple, RTD |

| Communication Protocols | Modbus TCP/IP, Profibus DP, Ethernet/IP |

| Output Signals | 4–20 mA, 0–10 V DC, relay contacts (5 A/250 V AC) |

| Power Supply | 100–240 V AC (50/60 Hz) or 24 V DC |

| Physical Dimensions | 190 mm (H) × 150 mm (W) × 220 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Protection Rating | IP65 (front panel), IP20 (rear panel) |

| Country of Origin | Switzerland |

VM600 IOC16T 200-565-000-013 200-565-101-013

Key Features and Advantages :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

Multi-Channel Data Acquisition: The VM600 IOC16T handles 16 simultaneous input/output channels, supporting a mix of dynamic vibration signals and static process parameters. This versatility eliminates the need for multiple standalone devices, simplifying system architecture and reducing installation costs. Each channel can be individually configured for sensor type, measurement range, and alarm thresholds, adapting to diverse machinery monitoring needs.

Advanced Signal Processing: Equipped with a dual-core processor, the controller performs real-time Fourier transform (FFT) analysis, peak detection, and trend logging, providing detailed insights into machinery condition. Its built-in 1GB data storage allows for historical data retrieval, enabling operators to identify developing faults through long-term trend analysis. This proactive approach minimizes unplanned downtime by addressing issues before they escalate.

Robust Environmental Resilience: The IP65-rated front panel protects against dust and water jets, while the rugged aluminum casing withstands mechanical shocks (50 g peak) and vibrations (20 g rms). The controller’s -40°C to +70°C operating range makes it suitable for extreme environments, from arctic oil rigs to high-temperature industrial furnaces.

Seamless System Integration: With support for Modbus TCP/IP, Profibus DP, and Ethernet/IP, the VM600 IOC16T integrates effortlessly with both legacy and modern control systems. Its web-based configuration tool allows remote access for parameter adjustment and firmware updates, reducing onsite maintenance requirements. The controller also supports OPC UA for secure data exchange with cloud-based analytics platforms, enabling Industry 4.0 applications.

Redundant Design for High Availability: Optional dual power supplies and communication ports ensure continuous operation even during component failures. This redundancy is critical for mission-critical applications where data loss could lead to costly downtime or safety incidents.

VM600 IOC16T 200-565-000-013 200-565-101-013

Application Areas :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

The VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 intelligent controller is essential for industries reliant on rotating machinery performance:

-

Power Generation: Monitors steam and gas turbines, generators, and pumps in thermal, nuclear, and renewable energy plants. By tracking vibration amplitude, bearing temperature, and shaft displacement, it prevents imbalances and misalignments that could disrupt power output. For example, in a combined-cycle power plant, the controller ensures stable operation of the turbine-generator set, minimizing maintenance costs and maximizing energy efficiency.

-

Oil & Gas: Deployed in refineries, offshore platforms, and pipeline compressor stations to monitor reciprocating compressors, centrifugal pumps, and electric motors. Its ability to withstand harsh conditions (saltwater mist, high humidity) makes it ideal for offshore environments, where early detection of bearing wear or seal leakage can prevent environmental hazards and production losses.

-

Industrial Manufacturing: Used in steel mills, cement plants, and chemical processing facilities to monitor crushers, fans, and extruders. The controller’s real-time data helps optimize maintenance schedules for high-value assets, ensuring consistent production quality and reducing downtime in critical processes like steel rolling or plastic extrusion.

-

Marine Engineering: Installed on ships and offshore vessels to monitor propulsion systems, diesel engines, and auxiliary machinery. Its compact design and rugged construction meet marine safety standards, providing reliable machinery health data during long voyages or in harsh ocean conditions.

-

Water and Wastewater Treatment: Tracks the condition of pumps, blowers, and mixers in treatment plants, ensuring continuous operation of water supply and sewage systems. By detecting abnormal vibration patterns, it helps maintain regulatory compliance and prevent service interruptions.

VM600 IOC16T 200-565-000-013 200-565-101-013

Related Products :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

- VM600 PWR24 Power Supply Module: Provides redundant 24 V DC power to the VM600 IOC16T, ensuring stable operation in unstable power environments.

- VM600 DISPLAY200 HMI Panel: A Use the human-machine interface in conjunction that visualizes real-time data from the VM600 IOC16T, enabling local monitoring and parameter adjustment.

- VM600 ACC100 Accelerometer: A high-sensitivity vibration sensor compatible with the VM600 IOC16T, designed for measuring high-frequency vibrations in rotating machinery.

- VM600 PROX300 Proximity Probe: Measures shaft displacement and eccentricity when paired with the VM600 IOC16T, critical for detecting rotor misalignment.

- VM600 COMPACT Miniature Controller: A scaled-down version of the VM600 IOC16T with 8 channels, suitable for smaller machinery or budget-sensitive applications.

- VM600 ANALYZER Software Suite: Advanced analytics software that integrates with the VM600 IOC16T to generate detailed health reports and predictive maintenance recommendations.

- VM600 RACK19 Enclosure: A 19-inch rack mount housing that accommodates the VM600 IOC16T and up to 8 additional modules, expanding system capacity for large-scale monitoring.

Installation and Maintenance :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

Installation Preparation:

Before installing the VM600 IOC16T, verify the power supply matches the rated voltage (100–240 V AC or 24 V DC) and ensure the mounting surface is flat and well-grounded to minimize electromagnetic interference. Use the provided DIN rail brackets to secure the controller in the VM600 Rack or a compatible enclosure. Connect field sensors to the terminal blocks, following the color-coded wiring diagram in the user manual, and terminate communication cables using shielded twisted-pair wires to maintain signal integrity. Finally, power on the controller and use the web interface to configure channel settings and communication protocols.

Before installing the VM600 IOC16T, verify the power supply matches the rated voltage (100–240 V AC or 24 V DC) and ensure the mounting surface is flat and well-grounded to minimize electromagnetic interference. Use the provided DIN rail brackets to secure the controller in the VM600 Rack or a compatible enclosure. Connect field sensors to the terminal blocks, following the color-coded wiring diagram in the user manual, and terminate communication cables using shielded twisted-pair wires to maintain signal integrity. Finally, power on the controller and use the web interface to configure channel settings and communication protocols.

Maintenance Recommendations:

- Routine Inspections: Monthly checks include verifying power supply voltage, cleaning dust from the ventilation slots, and ensuring all connections are tight. Use the built-in diagnostic LEDs to monitor status: a green light indicates normal operation, while a red light signals a fault that requires immediate attention.

- Sensor Calibration: Annually calibrate connected sensors using VIBRO-METER’s certified calibration tools to maintain measurement accuracy. This step is critical for ensuring reliable vibration and temperature data, especially in high-precision applications.

- Firmware Updates: Periodically download the latest firmware from VIBRO-METER’s official website and update the controller via the web interface. Firmware updates often include performance improvements and compatibility enhancements for new sensors or protocols.

- Redundancy Testing: For systems using dual power supplies or communication modules, test the redundancy functionality quarterly to ensure failover mechanisms work seamlessly. Replace any faulty components immediately to maintain system reliability.

VM600 IOC16T 200-565-000-013 200-565-101-013

Product Warranty :VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013

We provide a 12-month quality warranty for the VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 intelligent controller, covering hardware defects caused by non-human factors. During the warranty period, if the product exhibits abnormal performance or functional failure, we will promptly provide a replacement at no additional cost. For discontinued models or urgent requirements, our global supply chain network—built over 17 years of expertise in industrial control distribution—enables fast sourcing of even the rarest spare parts, minimizing downtime for your critical systems.

Our commitment extends beyond warranty: we offer 24/7 technical support to assist with installation, configuration, and troubleshooting, ensuring your team can maximize the controller’s capabilities. Trust in our proven track record of delivering reliable, high-quality industrial automation components that empower your operations to run safer, more efficiently, and with greater predictability.

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and safety guidelines.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

VIBRO-METER VM600 204-040-100-012 Program module

VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013 Module connector

VIBRO-METER VM600 CPUM 200-595-067-114 Servo module

VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017 Control cabinet node unit

HONEYWELL TC-CCN014 Control processor

Mitsubishi R28TB Switch quantity input card

PIONEER MAGNETICS PM3398B-6-1-3-E 80026-172-24 CPU module

WATLOW ANAFAZE 997D-11CC-JURG Pulse input (PI) module

WOODWARD 5501-471 Digital input module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: