Description

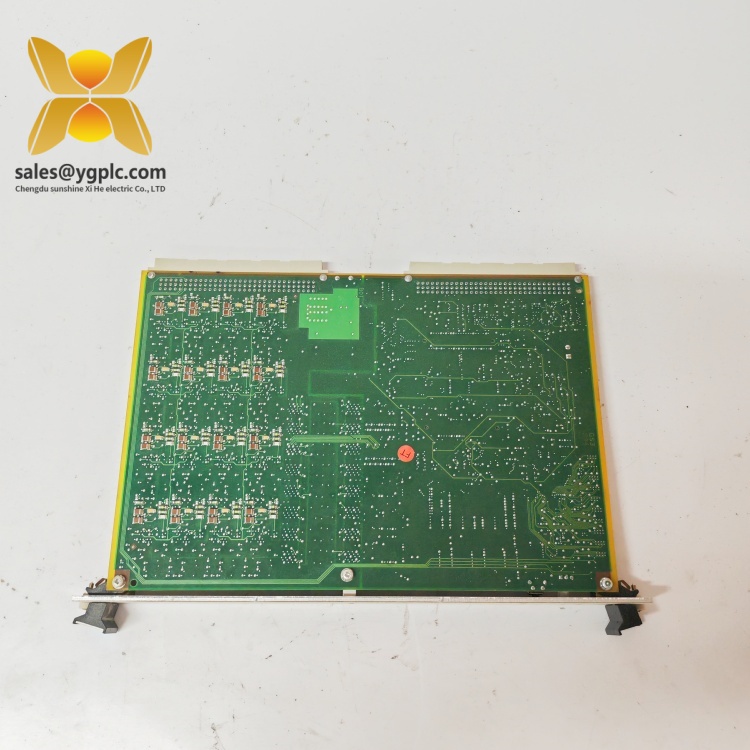

Product Overview:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

Technical Specifications:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VM600 CMC16 200-530-025-014 200-530-111-013 |

| Manufacturer | VIBRO-METER |

| Product Type | Machinery Condition Monitoring System |

| Channels | 2 analog input channels (configurable) |

| Input Types | Proximity probes (8 mm), accelerometers (IEPE), thermocouples |

| Communication Protocols | Modbus TCP/IP, 4–20 mA analog outputs |

| Physical Dimensions | 220 mm (H) × 150 mm (W) × 100 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -20°C to +70°C |

| Humidity | 5–95% non-condensing |

| Protection Rating | IP65 |

| Power Supply | 100–240 V AC, 50/60 Hz |

| Country of Origin | Switzerland |

VM600 CMC16 200-530-025-014 200-530-111-013

Key Features and Advantages:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

User-Centric Interface: The intuitive LCD display and menu-driven navigation simplify setup and maintenance, reducing training time for operators. Remote access via Ethernet enables real-time data viewing and configuration from anywhere in the plant, enhancing operational agility.

VM600 CMC16 200-530-025-014 200-530-111-013

Application Areas:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

- Power Generation: Monitors steam and gas turbines, generators, and pumps in thermal and nuclear power plants. The system’s vibration analysis capabilities help detect rotor imbalances and bearing defects, preventing catastrophic failures and ensuring stable energy production.

- Oil & Gas: Used in refineries, offshore platforms, and pipeline compressor stations to monitor critical equipment such as centrifugal pumps and reciprocating compressors. Its IP65 rating makes it suitable for explosive atmospheres when paired with certified sensors.

- Manufacturing: Integrates with production lines to monitor CNC machines, conveyor belts, and industrial fans. Real-time data helps optimize maintenance schedules, reducing downtime in high-volume manufacturing environments.

- Water Treatment: Tracks vibration and temperature of pumps and blowers in wastewater treatment plants, ensuring continuous operation and compliance with environmental regulations.

- Aerospace and Defense: Supports condition monitoring of aircraft ground support equipment and military machinery, where reliability and precision are non-negotiable.

VM600 CMC16 200-530-025-014 200-530-111-013

Related Products:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

- VM600 PSM16 Pressure Sensor Module:sets with the VM600 CMC16 to monitor process pressures, providing contextual data for vibration analysis.

- VM600 ADM16 Analog Output Module: Expands the system’s connectivity by converting digital data into analog signals for legacy control systems.

- VM600 TSM16 Temperature Monitoring Module: Adds thermal analysis capabilities, ideal for applications requiring combined vibration and temperature trending.

- VM600 EVM16 Event Management Module: Enhances alarm handling with real-time event logging and notification features, improving response times to critical issues.

- VM600 SSM16 Speed Sensor Module: Provides precise rotational speed measurements, essential for synchronizing machinery in complex systems.

- VM600 RFM16 Remote Fault Monitoring System: Enables wireless data transmission from the VM600 CMC16 to cloud-based platforms, supporting remote diagnostics and predictive analytics.

- VM600 DDM16 Data Display Module: Offers a dedicated local display for real-time vibration data, complementing the system’s remote monitoring capabilities.

Installation and Maintenance:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

Before installing the VM600 CMC16, verify the power supply (100–240 V AC) and ensure the mounting location meets IP65 environmental requirements. Clean the surface and secure the enclosure using the provided brackets. Connect sensors to the designated input channels (e.g., proximity probes to Channel 1, accelerometers to Channel 2) and terminate cables with proper strain relief. Configure communication settings (IP address, Modbus port) using the front-panel keypad or remote software.

- Routine Inspections: Monthly checks should include visual inspection of the enclosure for damage, verification of sensor connections, and review of alarm logs. Clean the LCD screen and vents to prevent dust accumulation.

- Calibration: Annually calibrate sensors and the VM600 CMC16 using VIBRO-METER’s certified calibration tools. Ensure probe linearity and amplifier gain meet factory specifications.

- Firmware Updates: Periodically update the system’s firmware via the USB port or Ethernet connection to access new features and security patches.

- Spare Parts Management: Maintain a stock of critical components, such as VM600 CMC16 replacement modules and sensor cables, to minimize downtime in case of failure.

VM600 CMC16 200-530-025-014 200-530-111-013

Product Warranty:VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013

Note: All product names and trademarks belong to their respective owners. This document is for informational purposes and does not substitute official technical documentation. Always refer to VIBRO-METER’s manuals for installation and safety guidelines.

ELAU MC-4/11/01/400 Motion controller

HONEYWELL R7247C1001 System-wide spare parts

HONEYWELL TC-CCN014 ITCC controller

Mitsubishi R28TB Fault tolerant control system

PIONEER MAGNETICS PM3398B-6-1-3-E 80026-172-24 Safety system module

WATLOW ANAFAZE 997D-11CC-JURG Network communication card

HONEYWELL TC-CCN014 ITCC controller

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: