Description

VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 Product Specification

Product Overview :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

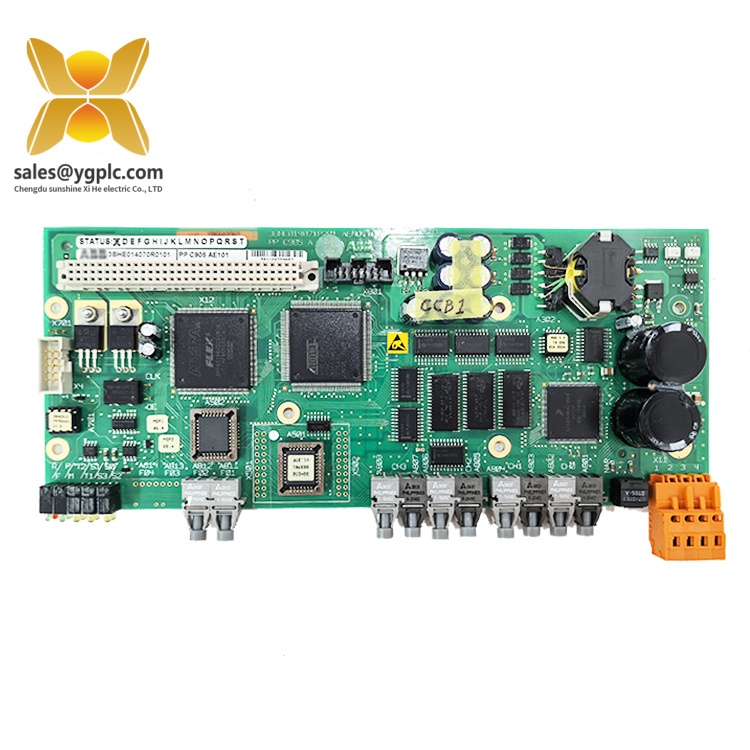

The VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 is a high-precision vibration monitoring and protection system module designed for critical rotating machinery in industrial automation. Manufactured by VIBRO-METER, a trusted brand in condition monitoring solutions, this module is part of the VM600 series, renowned for its reliability in detecting and analyzing machinery vibrations to prevent unexpected failures. As a key component in predictive maintenance systems, the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 integrates advanced signal processing and real-time data acquisition to ensure the operational integrity of turbines, compressors, and pumps across industries such as power generation, oil and gas, and manufacturing.

Featuring a dual-channel design, the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 supports both analog and digital input signals from proximity probes, velocity sensors, and accelerometers. It processes these signals to generate critical parameters such as vibration amplitude, frequency, and phase, which are essential for evaluating machinery health. The module’s high-speed microprocessor enables real-time trend analysis and alarm triggering, allowing operators to intervene before minor issues escalate into costly downtime. Compatible with the VM600 system’s distributed architecture, this module seamlessly integrates with other I/O units and the central controller, forming a robust monitoring network for large-scale industrial plants.

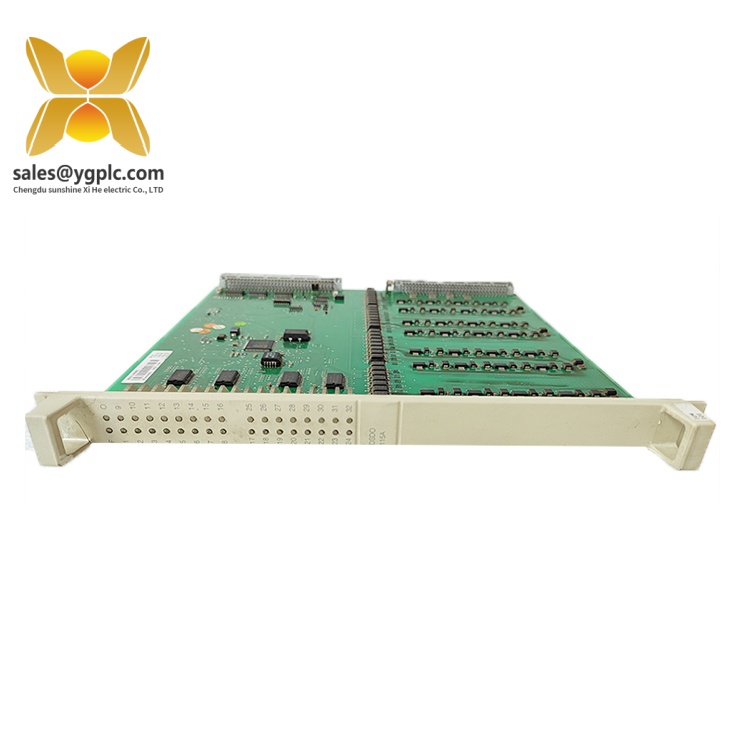

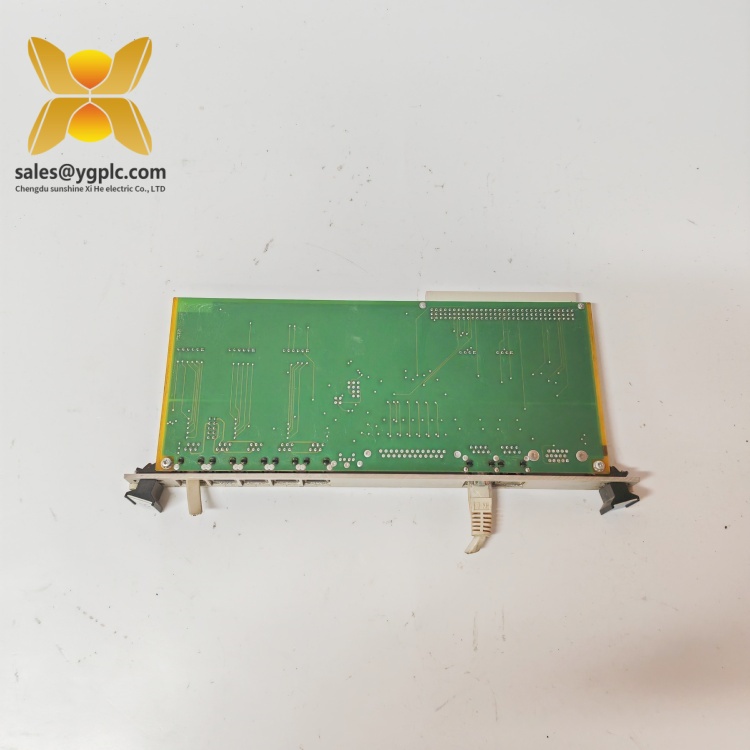

In automation systems, the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 serves as a frontline defense against mechanical failures, reducing reliance on reactive maintenance strategies. Its compact design (177.8 mm height × 482.6 mm width × 228.6 mm depth) and rack-mountable form factor facilitate easy installation in control cabinets, while its rugged construction ensures reliable performance in harsh environments with temperatures ranging from -20°C to +60°C. By providing continuous, accurate vibration data, this module empowers industries to optimize machinery lifecycle management, enhance operational efficiency, and maintain regulatory compliance.

Technical Specifications :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 |

| Manufacturer | VIBRO-METER |

| Product Type | Vibration Monitoring and Protection Module |

| Input Channels | 2 channels (analog/digital) |

| Sensors Supported | Proximity probes, velocity sensors, accelerometers |

| Communication Protocols | Modbus TCP, Profibus DP, Ethernet/IP |

| Power Supply | 100–240 VAC, 50/60 Hz |

| Physical Dimensions | 177.8 mm (H) × 482.6 mm (W) × 228.6 mm (D) |

| Weight | 4.5 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5%–95% non-condensing |

| Installation | 19-inch rack-mountable |

| Certifications | CE, UL, CSA |

VM600 IOCN 200-566-000-112 200-566-101-013

Main Features and Advantages :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

Dual-Channel Signal Processing: The VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 processes two independent sensor inputs simultaneously, enabling comprehensive monitoring of multi-axis vibrations in complex machinery setups. This feature enhances diagnostic accuracy by capturing both radial and axial vibration patterns, critical for identifying issues like misalignment or bearing wear.

Real-Time Alarm and Trend Analysis: Equipped with advanced algorithms, the module continuously analyzes vibration data to detect anomalies and trigger alarms via relay outputs or digital communication channels. Its built-in trend logging capability stores historical data for long-term performance analysis, supporting predictive maintenance strategies and reducing unplanned downtime.

Multi-Protocol Connectivity: With support for Modbus TCP, Profibus DP, and Ethernet/IP, the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 integrates seamlessly with both legacy and modern control systems, including DCS and SCADA platforms. This flexibility allows it to serve as a unified monitoring solution across diverse industrial environments.

Rugged Industrial Design: Built to withstand harsh conditions, the module features a metal enclosure with anti-vibration mounting and electromagnetic compatibility (EMC) compliance. Its wide operating temperature range and resistance to dust and moisture make it suitable for challenging environments such as offshore oil rigs, power plant turbine rooms, and manufacturing floors.

User-Friendly Configuration: The module is configurable via VIBRO-METER’s dedicated software, offering a intuitive interface for setting alarm thresholds, calibrating sensors, and configuring communication parameters. This reduces setup time and minimizes the risk of human error during installation or maintenance.

VM600 IOCN 200-566-000-112 200-566-101-013

Application Areas :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

The VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 is essential for industries reliant on rotating machinery, providing critical insights into equipment health:

-

Power Generation:

- Monitors steam and gas turbines, generators, and pumps in thermal and nuclear power plants, ensuring stable energy production and preventing catastrophic failures.

- Detects early signs of blade erosion or shaft misalignment, enabling timely maintenance to avoid grid disruptions.

-

Oil and Gas:

- Installed in compressors, motors, and centrifugal pumps in upstream and downstream facilities, the module supports continuous operation in harsh environments.

- Integrates with safety systems to trigger shutdowns in the event of excessive vibration, protecting personnel and equipment in high-risk scenarios.

-

Manufacturing:

- Optimizes production lines by monitoring high-speed rotating equipment such as spindles, conveyors, and robotic arms in automotive and pharmaceutical industries.

- Reduces downtime by identifying imbalance issues in rotating components before they cause quality defects or production delays.

-

Water and Wastewater Treatment:

- Monitors pumps and mixers in treatment plants, ensuring consistent water quality by preventing unexpected equipment failures.

- Provides remote access to vibration data for centralized monitoring across multiple sites, improving operational efficiency.

VM600 IOCN 200-566-000-112 200-566-101-013

Related Products :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

- VIBRO-METER VM600 PWR 200-566-000-101: A redundant power supply module for the VM600 system, ensuring uninterrupted operation by providing backup power to the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 and other components.

- VIBRO-METER VM600 COM 200-566-000-102: A communication gateway module that expands the system’s connectivity options, supporting protocols like OPC UA for integration with cloud-based monitoring platforms.

- VIBRO-METER VM600 AIN 200-566-000-103: An analog input module for additional sensor channels, complementing the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 in multi-sensor applications.

- BENTLY NEVADA 3500/22M: A compatible vibration monitoring module from BENTLY NEVADA (parent company of VIBRO-METER), offering similar functionality with enhanced diagnostic features for critical machinery.

- VIBRO-METER VM600 SOFTWARE 200-566-000-100: A dedicated software suite for data visualization, trend analysis, and alarm management, designed to work seamlessly with the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013.

Installation and Maintenance :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

Installation Preparation:

Before installing the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013, ensure the following:

Before installing the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013, ensure the following:

- Verify the power supply matches the module’s specifications (100–240 VAC) and ensure proper grounding to minimize electromagnetic interference.

- Mount the module in a 19-inch rack using the provided brackets, leaving adequate space for airflow to maintain optimal operating temperatures.

- Connect sensor cables using shielded twisted-pair wiring to prevent signal degradation, and configure communication settings via the module’s front-panel interface or dedicated software.

Maintenance Recommendations:

- Regularly inspect the module’s LED indicators to verify power status, communication connectivity, and alarm conditions.

- Perform annual calibration of sensors connected to the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013 using certified calibration tools to ensure measurement accuracy.

- Update the module’s firmware periodically to access the latest features and security patches, following the manufacturer’s guidelines to avoid data loss.

- Clean the module’s enclosure and ventilation slots quarterly to prevent dust accumulation, which can affect heat dissipation in high-temperature environments.

VM600 IOCN 200-566-000-112 200-566-101-013

Product Warranty :VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013

Our company provides a one-year quality warranty for the VIBRO-METER VM600 IOCN 200-566-000-112 200-566-101-013, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems.

Note: This product description is based on comprehensive research from technical datasheets and industry applications. For detailed operational guidelines, consult the official VIBRO-METER manual or contact our technical support team.

Contact Information:

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

WATLOW ANAFAZE 997D-11CC-JURG Pulse input (PI) module

WOODWARD 5501-471 Digital input module

BENTLY 3500/77M 176449-07 Digital 24VDC output module

COEN ISCAN DSF-2000-MB-UV 2653-213-06 Digital output module 24VDC

FOXBORO FCP270 P0917YZ Output module

SCHROFF MPS022 Analog input terminal board

ELAU MC-4/11/01/400 Motion controller

HONEYWELL R7247C1001 System-wide spare parts

FOXBORO P0926GV FBM231 Digital output module

AMAT 0010-23716 Digital relay output module

GE IS200TSVCH1AED PXI module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: