Description

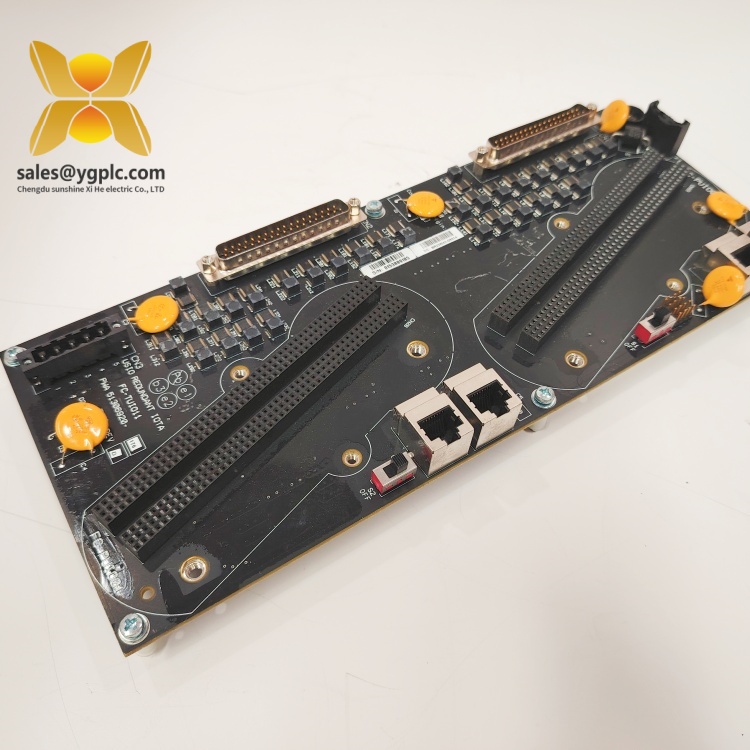

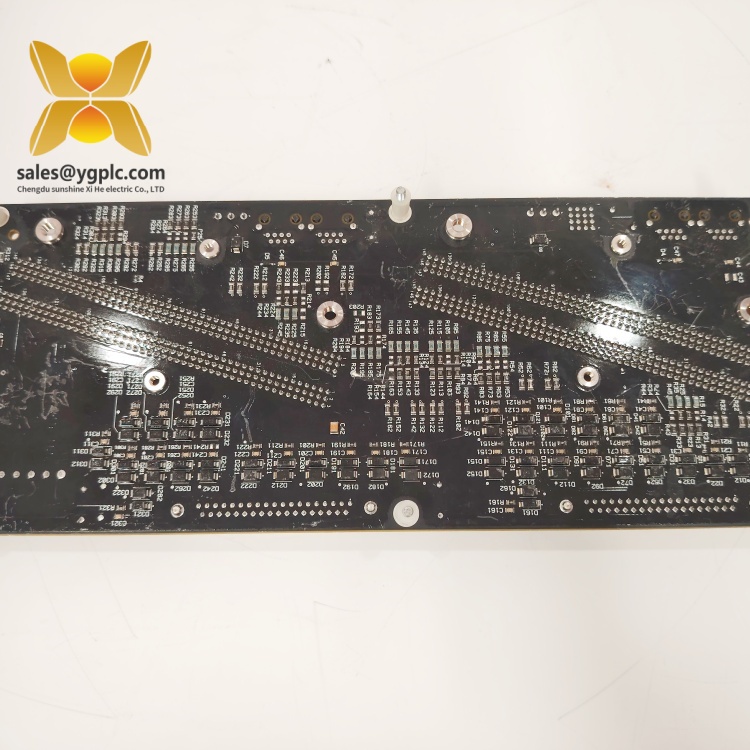

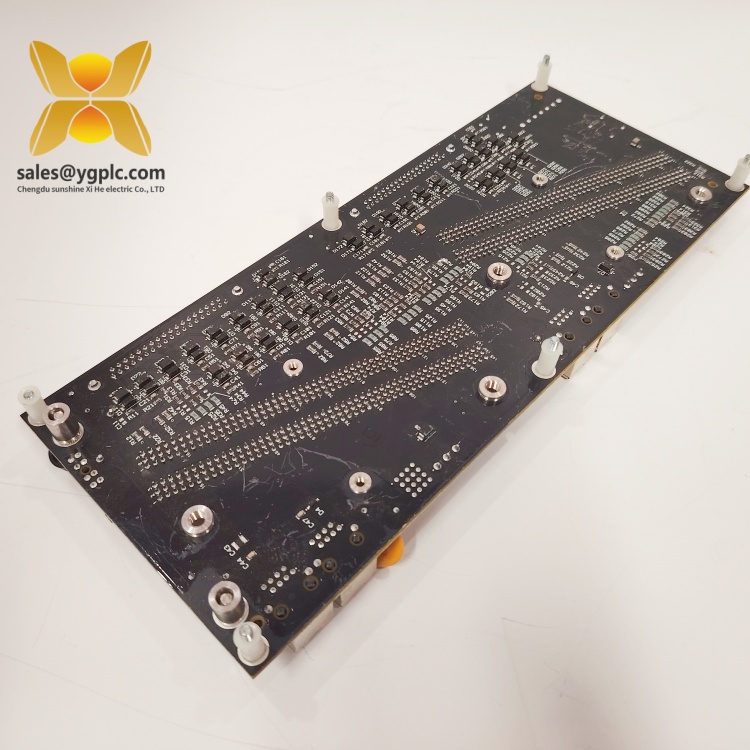

Honeywell FC-PUIO01 Process Universal I/O Module

Product Overview :Honeywell FC-PUIO01

The Honeywell FC-PUIO01 process universal I/O module is a high-performance industrial component designed to enhance the connectivity and flexibility of automation systems within Honeywell’s Experion Process Knowledge System (PKS). As a core component of the Field Device Manager (FDM) platform, this module serves as a critical interface between field devices, control systems, and human-machine interfaces (HMIs), enabling seamless integration of analog and digital signals in complex industrial environments. Its primary function is to provide universal input/output capabilities, supporting a wide range of signal types to simplify system configuration and reduce hardware redundancy.

Engineered for reliability and adaptability, the FC-PUIO01 supports 4–20 mA analog inputs/outputs, digital inputs/outputs (DI/DO), and relay outputs, making it suitable for diverse applications ranging from basic monitoring to advanced process control. The module’s 24V DC power supply and compact design (170mm x 100mm x 60mm, 1.2 kg) facilitate installation in standard control cabinets, while its -40°C to 70°C operating temperature range and IP20 protection rating ensure resilience in harsh industrial conditions. As part of Honeywell’s Experion PKS, the FC-PUIO01 integrates seamlessly with other system components, such as controllers and communication gateways, to create a unified automation architecture.

In automation systems, the FC-PUIO01 plays a pivotal role in optimizing data flow and control accuracy. Its universal I/O capabilities eliminate the need for multiple specialized modules, reducing upfront costs and maintenance complexity. By supporting real-time data acquisition and precise signal transmission, the module enhances the responsiveness of control loops, enabling operators to monitor and adjust processes in real time. This is particularly valuable in industries where process stability, safety, and efficiency are non-negotiable, such as oil & gas, chemical processing, and power generation.

Technical Specifications :Honeywell FC-PUIO01

| Parameter Name | Parameter Value |

|---|---|

| Product Model | FC-PUIO01 |

| Manufacturer | Honeywell |

| Product Type | Process Universal I/O Module |

| Input Voltage | 24V DC ±15% |

| Signal Types | 4–20 mA (AI/AO), DI/DO (24V DC), relay outputs |

| Channel Count | 8 channels (configurable as AI/AO/DI/DO) |

| Physical Dimensions | 170mm (W) x 100mm (H) x 60mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to 70°C |

| Humidity Resistance | 5–95% non-condensing |

| Mounting Type | DIN rail or rack-mounted |

| Country of Origin | United States |

| Communication Protocol | Profibus DP, Modbus RTU/TCP |

Honeywell FC-PUIO01

Main Features and Advantages :Honeywell FC-PUIO01

Universal I/O Flexibility: The FC-PUIO01 stands out for its ability to support multiple signal types on a single module, allowing each channel to be configured as analog input, analog output, digital input, or digital output. This flexibility reduces the need for separate modules, simplifying inventory management and system design. For example, a single FC-PUIO01 can interface with pressure transmitters (4–20 mA AI), control valves (4–20 mA AO), proximity switches (DI), and motor starters (DO), streamlining hardware integration.

High Precision and Reliability: With advanced signal conditioning and built-in diagnostics, the module ensures accurate data acquisition and transmission. Its 16-bit analog-to-digital conversion provides precise measurement resolution, while galvanic isolation between channels protects against electrical noise and ground loops. This reliability is critical in applications such as batch processing or continuous manufacturing, where signal integrity directly impacts product quality and process safety.

Scalable and Modular Design: The FC-PUIO01 is part of Honeywell’s modular Experion PKS ecosystem, enabling easy expansion of I/O capacity as needed. Its hot-swappable design allows for module replacement without powering down the system, minimizing downtime during maintenance or upgrades. Additionally, the module supports auto-calibration and self-diagnostic functions, reducing manual intervention and enhancing operational efficiency.

Seamless System Integration: Designed to work seamlessly with Honeywell’s Experion PKS controllers and HMIs, the FC-PUIO01 leverages Honeywell’s Universal Control Network (UCN) and Ethylene Oxide (EO) protocols for fast data exchange. This integration enables real-time monitoring and control through the Experion HMI, providing operators with a unified view of the entire process. The module also supports third-party systems via Profibus and Modbus, making it suitable for hybrid automation environments.

Honeywell FC-PUIO01

Application Areas :Honeywell FC-PUIO01

The Honeywell FC-PUIO01 process universal I/O module is widely applied in industries that require versatile and reliable signal management:

- Oil and Gas: Used in refineries, petrochemical plants, and offshore platforms to monitor and control flow rates, pressures, and temperatures. The module interfaces with field devices such as flow meters, level transmitters, and emergency shutdown valves, ensuring compliance with safety standards like IEC 61511.

- Chemical and Pharmaceutical Manufacturing: Supports precise control of batch processes, including dosing, mixing, and temperature regulation. The FC-PUIO01’s ability to handle both analog and digital signals makes it ideal for integrating with analytical instruments, agitators, and sterilization systems.

- Power Generation: Deployed in thermal and renewable energy plants to manage boiler controls, turbine operations, and switchyard interfaces. The module’s rugged design withstands the high-temperature and high-vibration environments typical of power generation facilities.

- Water and Wastewater Treatment: Manages pump control, valve positioning, and quality monitoring in water treatment plants. For example, it can process analog signals from pH sensors and digital signals from motor starters, enabling automated adjustment of chemical dosing systems.

- Food and Beverage Production: Ensures hygienic and precise control of production lines, including filling machines, pasteurizers, and packaging systems. The module’s corrosion-resistant components and compliance with industry standards (e.g., FDA, CE) make it suitable for cleanroom environments.

Honeywell FC-PUIO01

Related Products :Honeywell FC-PUIO01

- FC-CPU01: A Honeywell Experion PKS controller that works in tandem with the FC-PUIO01 to execute control strategies and manage data flow within the automation system.

- FC-CON01: A communication gateway module that enables the FC-PUIO01 to interface with legacy systems via protocols like HART or Modbus, enhancing interoperability in mixed-technology environments.

- FC-AI02: A dedicated analog input module for high-channel-count applications, complementing the FC-PUIO01 in systems requiring extensive sensor integration.

- FC-DO02: A digital output module with relay contacts for high-power switching, suitable for applications where the FC-PUIO01’s built-in relays are insufficient.

- FC-RTB01: A terminal block module that provides a secure interface between the FC-PUIO01 and field wiring, simplifying installation and maintenance.

- FC-PS01: A redundant power supply module that ensures stable power delivery to the FC-PUIO01 and other Experion PKS components, minimizing downtime due to power fluctuations.

- FC-HMI01: A human-machine interface panel that integrates with the FC-PUIO01 to provide real-time process visualization and operator control.

Installation and Maintenance :Honeywell FC-PUIO01

Pre-installation Preparations:

Before installing the FC-PUIO01, verify that the control cabinet meets environmental requirements (e.g., temperature, humidity, and IP rating). Ensure the 24V DC power supply is stable and properly grounded to avoid electrical interference. Mount the module on a DIN rail or rack using the provided brackets, ensuring adequate spacing for heat dissipation. Connect field wires to the terminal blocks, following Honeywell’s wiring diagrams to match signal types (AI/AO/DI/DO) and ensure correct polarity for analog signals. Finally, configure the module via the Experion PKS engineering workstation, assigning channel types and calibration parameters as needed.

Before installing the FC-PUIO01, verify that the control cabinet meets environmental requirements (e.g., temperature, humidity, and IP rating). Ensure the 24V DC power supply is stable and properly grounded to avoid electrical interference. Mount the module on a DIN rail or rack using the provided brackets, ensuring adequate spacing for heat dissipation. Connect field wires to the terminal blocks, following Honeywell’s wiring diagrams to match signal types (AI/AO/DI/DO) and ensure correct polarity for analog signals. Finally, configure the module via the Experion PKS engineering workstation, assigning channel types and calibration parameters as needed.

Maintenance Recommendations:

Regular maintenance is essential to ensure the FC-PUIO01 operates at peak performance. Conduct monthly visual inspections to check for loose connections, damaged cables, or overheating. Use a soft brush or compressed air to clean dust from the module’s vents, preventing thermal buildup. Quarterly, verify signal accuracy using a calibrated loop calibrator for analog channels and a digital multimeter for digital channels. Annually, review the module’s firmware version and apply updates via Honeywell’s Asset Management Suite (AMS) to access new features and security patches. In the event of a fault, replace the module with a pre-configured spare to minimize downtime, ensuring the new unit is properly registered in the Experion PKS system.

Regular maintenance is essential to ensure the FC-PUIO01 operates at peak performance. Conduct monthly visual inspections to check for loose connections, damaged cables, or overheating. Use a soft brush or compressed air to clean dust from the module’s vents, preventing thermal buildup. Quarterly, verify signal accuracy using a calibrated loop calibrator for analog channels and a digital multimeter for digital channels. Annually, review the module’s firmware version and apply updates via Honeywell’s Asset Management Suite (AMS) to access new features and security patches. In the event of a fault, replace the module with a pre-configured spare to minimize downtime, ensuring the new unit is properly registered in the Experion PKS system.

Honeywell FC-PUIO01

Product Guarantee :Honeywell FC-PUIO01

Our company is committed to delivering superior quality with the Honeywell FC-PUIO01 process universal I/O module, backing it with a 12-month quality warranty. This warranty covers all non-human-induced hardware defects, providing replacement services at no cost should the module exhibit performance anomalies or functional failures during the warranty period. We understand the critical role of reliable I/O modules in industrial operations, which is why we prioritize prompt support and efficient resolution of any issues.

Beyond warranty services, our global supply chain network is equipped to address urgent needs, including discontinued or hard-to-find components like the FC-PUIO01. With 17 years of expertise in industrial control distribution, we offer competitive pricing, rapid delivery, and comprehensive technical support to ensure your automation system remains operational. Whether you require assistance with module configuration, troubleshooting, or system expansion, our team of experts is available to provide tailored solutions.

Contact us today to leverage the flexibility and reliability of the FC-PUIO01 in your industrial applications. Our commitment to quality and customer satisfaction ensures that you receive not just a product, but a partnership designed to enhance your operational efficiency and long-term success.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to Honeywell’s official manuals for detailed installation, operation, and safety guidelines.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

HONEYWELL R7247C1001 High density main box

HONEYWELL TC-CCN014 Remote extender module

EPRO MMS6120 9100-00002C-08 driver

EPRO MMS6120 9100-00002-10 servo

WOODWARD 5453-277 Eddy current sensor

GE CK11CE300 Safety system

PACIFIC 33VM52-000-29 PDP panel

Woodward 8237-1369 Remote module

Woodward 8237-1600 Main processor

ALSTOM CMP1838 TRVCO62345000 CP00005202 Pulse input

PEPPERL+FUCHS 2082 High density main box

PEPPERL+FUCHS 2108HAT Remote extender module

GE SR469 469-P5-HI-A20-E Input pulse module

GE IS220PDIAH1A Digital output module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: