Description

GE VMER-64 Vibration Monitoring Module

Product Overview:GE VMER-64

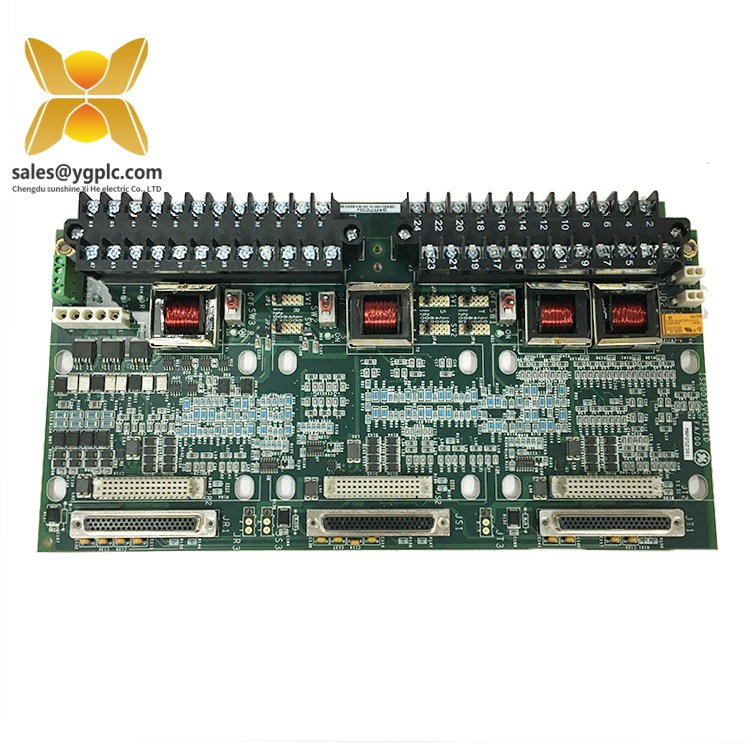

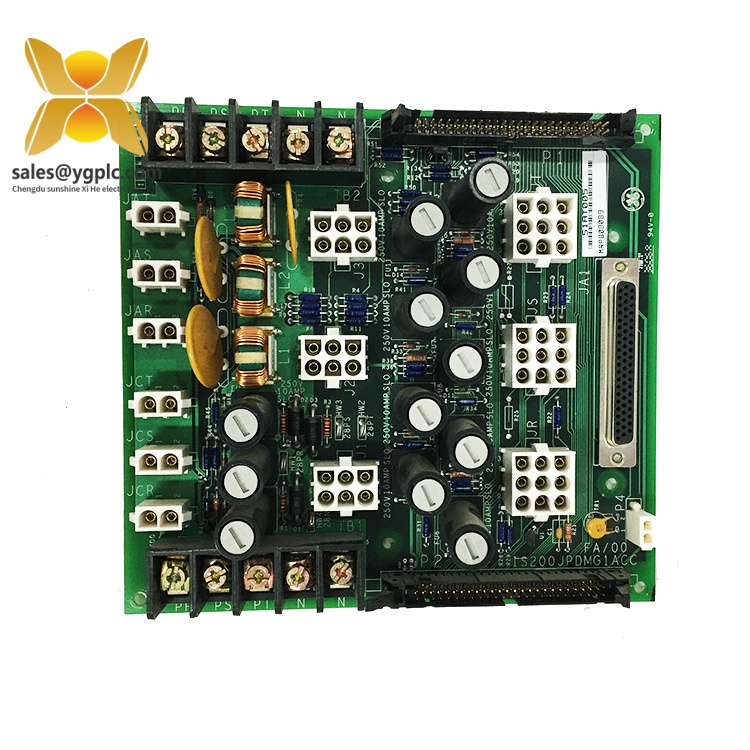

The GE VMER-64 is a high-performance Vibration Monitoring Module designed for industrial machinery health management, serving as a critical component in GE’s VersaMax™ automation platform. Engineered to deliver real-time vibration analysis for rotating equipment, the GE VMER-64 plays a pivotal role in predictive maintenance strategies across industries such as oil & gas, power generation, and manufacturing. By integrating advanced signal processing algorithms and multi-channel data acquisition, this module converts raw vibration data from accelerometers or proximity probes into actionable insights, enabling early detection of mechanical faults like imbalance, misalignment, or bearing wear.

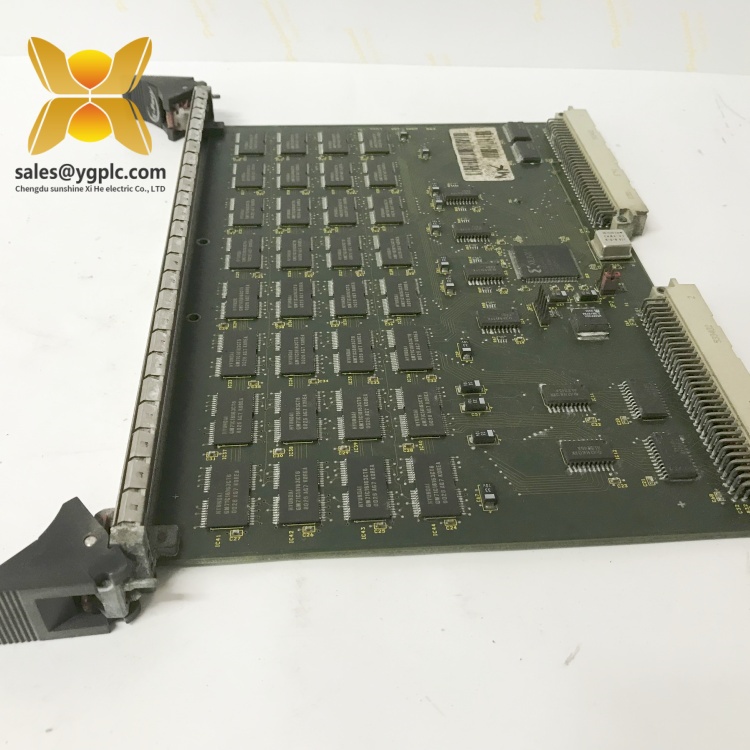

As part of the VersaMax™ I/O family, the GE VMER-64 offers 64 channels of simultaneous vibration monitoring, supporting both analog and digital input signals. Its modular design ensures seamless integration with GE’s PLC and SCADA systems, as well as third-party control platforms via open communication protocols. The module’s rugged construction and wide operating temperature range (-40°C to +85°C) make it suitable for harsh industrial environments, while its user-configurable alarm thresholds and diagnostic features enhance system reliability and reduce unplanned downtime.

In automation ecosystems, the GE VMER-64 acts as a cornerstone of machinery protection, bridging the gap between field sensors and higher-level control systems. Its ability to provide continuous, high-resolution vibration data allows maintenance teams to schedule targeted repairs, optimize equipment lifecycle, and minimize operational costs. Whether deployed in standalone applications or large-scale distributed systems, the GE VMER-64 ensures precise monitoring and control, solidifying its role as an indispensable asset for industries reliant on critical rotating assets.

Technical Specifications:GE VMER-64

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VMER-64 |

| Manufacturer | GE |

| Product Type | Vibration Monitoring Module |

| Input Channels | 64 (analog/digital, configurable) |

| Input Signal Types | Accelerometer (IEPE), proximity probes, tachometer pulses |

| Frequency Range | 0.1 Hz to 20 kHz |

| Resolution | 16-bit ADC |

| Output | 4–20 mA analog, Modbus TCP/IP, Profibus DP |

| Physical Dimensions | 178 mm (H) × 101.6 mm (W) × 254 mm (D) |

| Weight | 1.8 kg |

| Power Supply | 24 V DC ±15% |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted (standard 19-inch enclosure) |

| Certifications | CE, UL, CSA |

VMER-64

Key Features and Advantages:GE VMER-64

Comprehensive Multi-Channel Monitoring: The GE VMER-64 supports up to 64 vibration channels, allowing simultaneous monitoring of multiple points on complex machinery such as turbines, compressors, and motors. This scalability reduces the need for multiple standalone modules, simplifying system architecture and lowering hardware costs.

Advanced Signal Processing: Equipped with FFT (Fast Fourier Transform) and time-domain analysis capabilities, the module provides detailed vibration spectra and trend data. This enables precise identification of fault frequencies, facilitating root cause analysis and proactive maintenance planning.

Flexible Communication Interfaces: The VMER-64 integrates with GE’s VersaMax™ Controller and external systems via Modbus and Profibus, ensuring seamless data exchange with SCADA or CMMS (Computerized Maintenance Management Systems). Its dual Ethernet ports support network redundancy, enhancing system resilience in mission-critical applications.

Rugged Industrial Design: Built with a steel enclosure and conformal coating, the module withstands high vibration, shock, and electromagnetic interference (EMI). Its wide temperature range and IP20 rating make it suitable for both indoor and outdoor installations, including offshore platforms and heavy manufacturing facilities.

User-Configurable Alarms: The GE VMER-64 allows custom setting of warning and danger thresholds for each channel, with real-time alarm notifications via relay outputs or digital messages. This feature enables rapid response to developing faults, preventing catastrophic failures and minimizing downtime.

Easy Integration and Calibration: Compatible with GE’s Proficy™ HMI/SCADA software, the module offers intuitive configuration and calibration tools. Its plug-and-play design reduces installation time, while built-in self-diagnostics simplify troubleshooting and maintenance.

VMER-64

Application Areas:GE VMER-64

The GE VMER-64 is widely deployed in industries where machinery reliability is non-negotiable:

- Oil & Gas: Monitoring pumps, compressors, and gas turbines in refineries, pipelines, and offshore rigs to detect early signs of mechanical degradation, ensuring continuous production and safety compliance.

- Power Generation: Optimizing the performance of steam turbines, generators, and cooling systems in thermal, hydro, and wind power plants by providing real-time vibration data for load balancing and fault prediction.

- Manufacturing: Enhancing the efficiency of conveyor systems, robotic arms, and high-speed machinery in automotive, pharmaceutical, and food processing facilities by identifying misalignments or worn components before they cause downtime.

- Mining and Metals: Protecting large-scale crushers, mills, and ventilation systems in mining operations, where equipment failure can lead to significant production delays and safety risks.

Specific applications include:

- Condition-Based Maintenance (CBM): Replacing traditional time-based maintenance with data-driven strategies, reducing unnecessary repairs and extending equipment lifespan.

- Machinery Commissioning: Validating the mechanical integrity of new or refurbished equipment by analyzing vibration signatures during startup and load testing.

- Remote Monitoring: Providing real-time vibration data to remote operations centers, enabling centralized management of geographically dispersed assets.

Related Products:GE VMER-64

- GE VMER-32: A 32-channel variant of the VMER-64, suitable for smaller-scale applications or systems requiring fewer monitoring points.

- GE VMER-128: A high-density version with 128 channels, designed for large industrial complexes or multi-machine setups needing extensive vibration coverage.

- GE VMER-TC: A temperature and vibration combo module, integrating thermal monitoring with vibration analysis for comprehensive machinery health assessment.

- GE VersaMax™ Controller (VMX-2CPU): A programmable logic controller that pairs with the VMER-64 to execute control strategies based on vibration data.

- GE Proficy™ Machine Edition: Software for configuring and monitoring the VMER-64, offering advanced visualization and analytics tools.

- GE IC695ACC300 Accelerometer: A compatible IEPE sensor for high-frequency vibration measurement, optimized for use with the VMER-64.

- GE VMX-I/O Expansion Chassis: Extends the I/O capacity of the VMER-64 in distributed control systems, supporting up to 1,024 total channels.

- GE VIPRO-2000 Vibration Analyzer: A portable diagnostic tool for on-site vibration analysis, complementary to the VMER-64 for offline condition monitoring.

VMER-64

Installation and Maintenance:GE VMER-64

Installation Preparation:

Before installing the GE VMER-64, ensure the rack enclosure is properly grounded and ventilated. Verify compatibility with sensor types (e.g., accelerometers, proximity probes) and use shielded cables to minimize noise interference. Mount the module in a 19-inch rack, securing it with M4 screws, and connect the 24 V DC power supply. Use GE’s Proficy™ Machine Edition software to configure channel parameters, such as sensor type, scaling factors, and alarm thresholds.

Before installing the GE VMER-64, ensure the rack enclosure is properly grounded and ventilated. Verify compatibility with sensor types (e.g., accelerometers, proximity probes) and use shielded cables to minimize noise interference. Mount the module in a 19-inch rack, securing it with M4 screws, and connect the 24 V DC power supply. Use GE’s Proficy™ Machine Edition software to configure channel parameters, such as sensor type, scaling factors, and alarm thresholds.

Maintenance Recommendations:

- Routine Inspections: Conduct monthly visual checks for loose connections, overheating, or physical damage. Clean the module’s vents with compressed air to prevent dust accumulation, which can affect thermal performance.

- Calibration: Perform annual calibration using GE’s certified calibration tools to ensure accurate vibration measurements. Document calibration results for compliance with industry standards (e.g., ISO 17025).

- Firmware Updates: Periodically update the module’s firmware via GE’s software platform to access new features, security patches, and compatibility improvements with newer systems.

- Spare Parts Management: Maintain a spare VMER-64 module in a controlled environment (temperature: 20–25°C, humidity: 30–50% RH) to facilitate quick replacement in case of failure. Store sensors and cabling separately to ensure complete system redundancy.

Product Warranty:GE VMER-64

Our company provides a 12-month quality warranty for the GE VMER-64, covering non-human-induced hardware defects. During the warranty period, we offer prompt replacement services for modules experiencing performance anomalies or functional failures. For discontinued models or urgent requirements, our global supply chain network ensures efficient sourcing of rare components, minimizing downtime and supporting uninterrupted industrial operations. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering reliable solutions to maintain the long-term performance of your automation infrastructure.

For inquiries, contact our team via Whatsapp:+86 18859254943 or E-mail :sales@ygplc.com.

GE IS220PSCAH1A Switch input module

GE IS420UCSBH1A AO connection card

GE IS220UCSAH1A Digital output terminal board

GE IS220UCSAH1AK Logic control module

GE V7768-320000 3509301007768-320000A0 Switch input terminal board

GE IS200AEADH4A 109W3660P001 I/O fault diagnosis

GE HYDRAN M2 DCS module

GE IS220PDIAH1A Servo valve

GE CK11CE300 Analog inpu

GE IS220PSCAH1A Switch input module

GE IS420UCSBH1A AO connection card

GE IS220UCSAH1A Digital output terminal board

GE IS220UCSAH1AK Logic control module

GE V7768-320000 3509301007768-320000A0 Switch input terminal board

GE IS200AEADH4A 109W3660P001 I/O fault diagnosis

GE HYDRAN M2 DCS module

GE IS220PDIAH1A Servo valve

GE CK11CE300 Analog inpu

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: