Description

GE VME-PMC-CADDY Product Specification

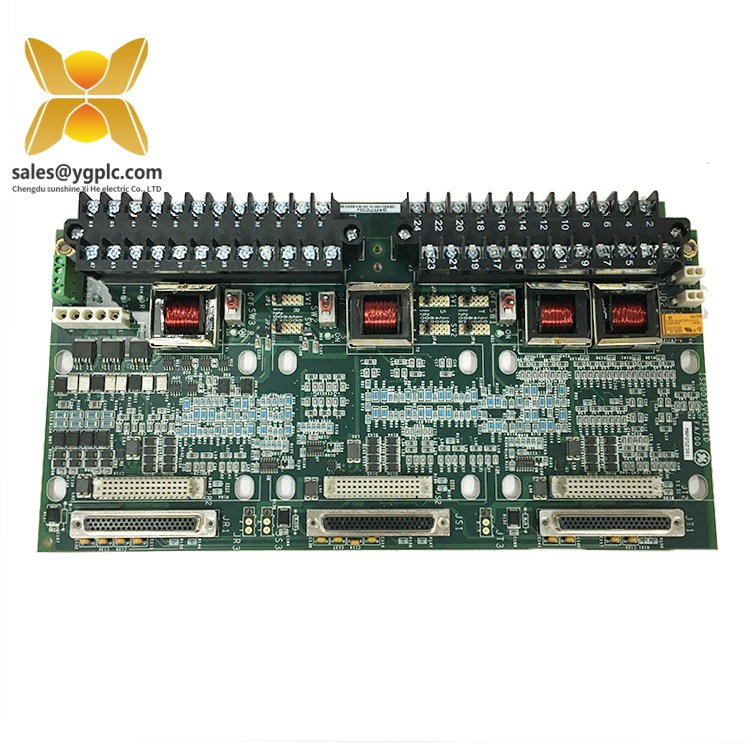

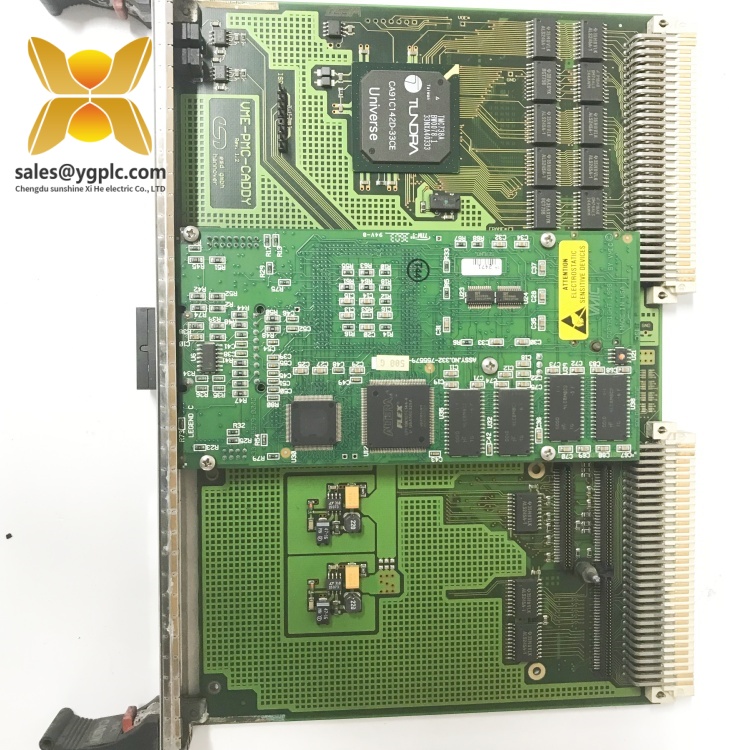

Product Overview:GE VME-PMC-CADDY

The :GE VME-PMC-CADDY is a high-performance VMEbus carrier board engineered for industrial automation systems, designed to seamlessly integrate and expand VMEbus-based control architectures. Developed by General Electric (GE), a global leader in power and automation solutions, this module is part of the VME64 platform, renowned for its robustness, scalability, and compatibility with a wide range of industrial protocols. The GE VME-PMC-CADDY serves as a critical component in distributed control systems (DCS), enabling the integration of up to two PMC (PCI Mezzanine Card) modules into a VMEbus system, thereby enhancing computational power and I/O capabilities across industries such as power generation, oil and gas, and aerospace.

At its core, the GE VME-PMC-CADDY features a VME64-compliant design with dual 160-pin VG connectors, supporting data widths of up to 32 bits and 32 address signals 1. It employs the Tundra Universe CA91C142 VME-PCI bridge, enabling high-speed data transfer between VMEbus and PCI-based systems, with a bandwidth optimized for real-time applications 1. The module supports both single-width and double-width PMC modules, offering flexibility for applications requiring specialized I/O processing, such as analog signal conditioning, digital control, or communication gateways. Its compact form factor (127.5 mm depth × 186 mm height × 59 mm width) and DIN rail mounting make it suitable for space-constrained environments while ensuring reliable operation in harsh industrial conditions 13.

In automation systems, the GE VME-PMC-CADDY acts as a bridge between VMEbus controllers and PMC modules, facilitating seamless integration of advanced functionalities into legacy or new control setups. Its redundant network architecture, with dual Ethernet ports and support for seven interrupt request lines, enhances system resilience against communication failures 1. By combining high-speed data processing with modular expandability, the GE VME-PMC-CADDY empowers industries to optimize operational efficiency, reduce downtime, and adapt to evolving automation requirements.

Technical Specifications:GE VME-PMC-CADDY i

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE VME-PMC-CADDY |

| Manufacturer | General Electric (GE) |

| Product Type | VMEbus Carrier Board for PMC Modules |

| Form Factor | VME64 (6U) |

| Physical Dimensions | 127.5 mm (depth) × 186 mm (height) × 59 mm (width) |

| Weight | 1.5 kg |

| Power Supply | 12 VDC ±10% |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Communication Interfaces | VME64, PCI, Ethernet, RS-232, RS-485 |

| Data Width | 32 bits |

| Address Signals | 32 |

| PMC Slots | 2 single-width or 1 double-width |

| Redundancy Support | Dual Ethernet ports, redundant power inputs |

| Certifications | CE, UL, CSA |

VME-PMC-CADDY

Main Features and Advantages:GE VME-PMC-CADDY

Modular Expandability: The GE VME-PMC-CADDY supports up to two PMC modules, allowing users to customize system functionality by integrating specialized I/O cards, communication gateways, or signal processing modules. This flexibility is particularly valuable in applications requiring hybrid control architectures, such as combining analog and digital inputs/outputs in a single system 18.

High-Speed Data Transfer: Leveraging the Tundra Universe CA91C142 VME-PCI bridge, the module achieves high-bandwidth data transfer between VMEbus and PCI-based systems, ensuring real-time responsiveness in critical applications like turbine control or high-speed production lines 1. Its 32-bit data path and 32 address signals enable efficient handling of large datasets and complex control algorithms.

Rugged Industrial Design: Built to withstand extreme conditions, the GE VME-PMC-CADDY operates reliably in temperatures ranging from -40°C to +85°C and resists vibration and shock. Its robust construction makes it suitable for deployment in harsh environments, such as offshore oil platforms, chemical plants, or outdoor power generation facilities 38.

Redundant Network Architecture: The dual Ethernet ports and seven interrupt request lines support redundant network configurations, minimizing the risk of communication failures. This feature is critical in mission-critical systems where continuous operation is non-negotiable, such as emergency shutdown systems in oil refineries 18.

User-Friendly Integration: The module is compatible with GE’s Proficy Machine Edition software, providing a unified platform for programming, diagnostics, and system configuration. Its DIN rail mounting and standardized interfaces simplify installation and retrofitting into existing VMEbus systems, reducing setup time and costs 18.

VME-PMC-CADDY

Application Areas:GE VME-PMC-CADDY

The GE VME-PMC-CADDY is widely deployed in industries where modularity, reliability, and high-performance computing are essential:

-

Power Generation:

- Integrates with gas and steam turbine control systems to monitor and optimize energy production. PMC modules can be added for real-time vibration analysis or predictive maintenance, ensuring grid stability and efficiency 38.

- Supports redundant communication in power plants, minimizing downtime during equipment upgrades or maintenance.

-

Oil and Gas:

- Manages distributed control systems in offshore platforms and refineries, enabling real-time monitoring of pressure, flow rates, and safety interlocks. The module’s SIL 3 compliance makes it suitable for emergency shutdown systems 18.

- Facilitates data integration between field devices and supervisory control systems, enhancing operational visibility and reducing response times to process anomalies.

-

Aerospace and Defense:

- Used in aircraft simulators and engine test stands to handle high-speed data acquisition and control. PMC modules can be configured for specialized tasks like flight control simulation or sensor fusion 8.

- Supports ruggedized environments, ensuring reliable performance in extreme temperatures and high-vibration conditions.

-

Manufacturing:

- Synchronizes robotics, conveyor systems, and quality control devices in automotive or pharmaceutical production lines. The module’s PCI expansion capability allows integration of motion control or vision systems 38.

- Enables predictive maintenance by analyzing sensor data to detect equipment wear or malfunctions before they escalate.

Related Products:GE VME-PMC-CADDY

- GE VMIPMC5579: An upgraded version of the GE VME-PMC-CADDY with enhanced PCIe compatibility and higher data throughput, ideal for next-generation industrial computing applications 615.

- GE IS210AEBIH1BED: A turbine control module designed for mission-critical power generation systems, often used alongside the GE VME-PMC-CADDY to manage real-time data processing and control algorithms 1.

- GE CI871AK01 3BSE092693R1: A Profinet IO communication module that complements the GE VME-PMC-CADDY in hybrid control systems, enabling seamless integration with ABB’s AC 800M controller platform 1.

- GE IC695CPU320: A PACSystems RX3i central processing unit that provides additional computational resources for large-scale control systems incorporating the GE VME-PMC-CADDY 1.

- GE DI818 3BSE069052R1: A digital input module for handling 24V DC signals, commonly used in conjunction with the GE VME-PMC-CADDY in hybrid I/O applications 1.

Installation and Maintenance:GE VME-PMC-CADDY

Pre-Installation Preparation:

Before installing the GE VME-PMC-CADDY, ensure the following:

Before installing the GE VME-PMC-CADDY, ensure the following:

- Verify the power supply meets the module’s requirements (12 VDC ±10%).

- Clean the installation area to prevent dust or debris from affecting performance.

- Use a compatible VMEbus backplane with 160-pin VG connectors to ensure mechanical and electrical compatibility 1.

- Configure the module using GE’s Proficy Machine Edition software to define PMC module parameters and network settings.

Maintenance Recommendations:

- Regularly inspect the module for physical damage or loose connections, especially in high-vibration environments.

- Monitor the module’s operating temperature and humidity levels to ensure they remain within specified ranges.

- Update firmware periodically to access the latest features and security patches, using GE’s dedicated software tools.

- Perform diagnostic tests to check communication integrity and system health, leveraging the module’s built-in LED indicators for quick status checks 18.

- For PMC modules, follow the respective manufacturers’ maintenance guidelines for calibration and replacement.

VME-PMC-CADDY

Product Warranty:GE VME-PMC-CADDY

Our company provides a one-year quality warranty for the GE VME-PMC-CADDY, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems.

Note: This product description is based on publicly available technical data and industry applications. For detailed specifications, consult the official GE datasheet or contact our technical support team.

GE IS420PUAAH1A Master control panel

GE IS220PSCAH1A Switch input module

GE IS420UCSBH1A AO connection card

GE IS220UCSAH1A Digital output terminal board

GE IS220UCSAH1AK Logic control module

GE V7768-320000 3509301007768-320000A0 Switch input terminal board

GE IS200AEADH4A 109W3660P001 I/O fault diagnosis

GE HYDRAN M2 DCS module

GE IS420ESWBH2A AO card

GE IS420PUAAH1A Master control panel

GE IS220PSCAH1A Switch input module

GE IS420UCSBH1A AO connection card

GE IS220UCSAH1A Digital output terminal board

GE IS220UCSAH1AK Logic control module

GE V7768-320000 3509301007768-320000A0 Switch input terminal board

GE IS200AEADH4A 109W3660P001 I/O fault diagnosis

GE HYDRAN M2 DCS module

GE IS420ESWBH2A AO card

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: