Description

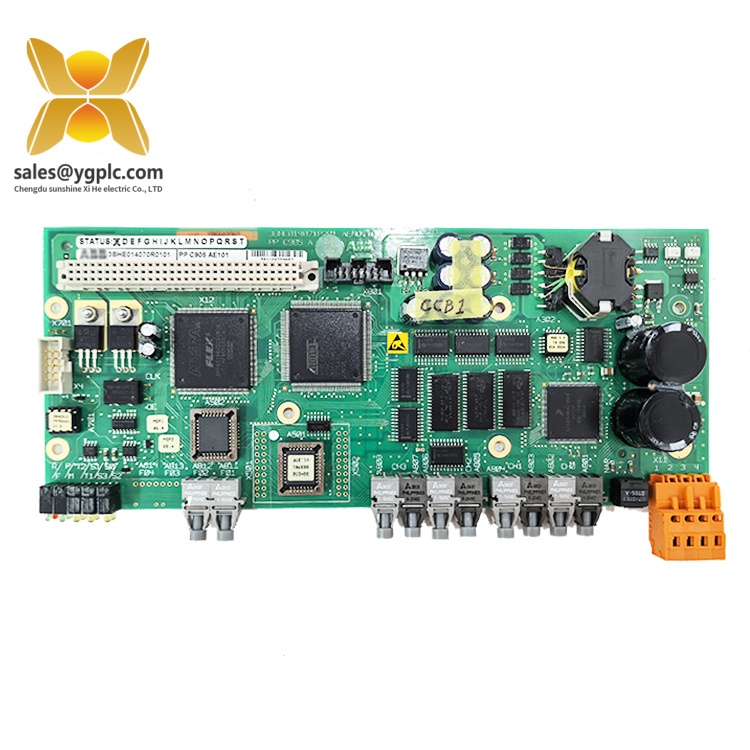

GE IS210MACCH2AGG Mark VIe Speedtronic Turbine Control Module

Product Overview

The GE IS210MACCH2AGG is a high-performance turbine control module designed as a core component of GE’s Mark VIe Speedtronic Turbine Control System, catering to mission-critical applications in power generation, oil & gas, and heavy industrial automation. Engineered to manage steam and gas turbine operations, this module provides precise speed regulation, load control, and safety interlock functions, ensuring reliable and efficient power generation in demanding environments. As part of the Mark VIe ecosystem, the IS210MACCH2AGG integrates seamlessly with other GE Fanuc components, such as I/O modules and communication gateways, to form a robust, scalable control architecture capable of handling complex turbine dynamics and process automation.

Featuring a rugged industrial design, the GE IS210MACCH2AGG supports hot-swappable installation, allowing maintenance or replacement without system downtime—a critical feature for 24/7 operations in power plants and refineries. Its advanced microprocessor-based control logic executes real-time turbine algorithms, including speed governing, valve positioning, and overspeed protection, while integrated diagnostic functions monitor system health and signal integrity. The module’s wide operating temperature range (-40°C to +70°C) and compliance with industry standards like IEC 61131-3 and API 670 ensure reliable performance in harsh environments, from offshore platforms to extreme climate zones. With a focus on safety, the IS210MACCH2AGG incorporates redundant communication pathways and fail-safe protocols to mitigate risks associated with turbine misoperation.

In automation systems, the IS210MACCH2AGG serves as the brain of the Mark VIe system, translating operator commands and sensor inputs into precise control actions. It interfaces with field devices such as proximity probes, thermocouples, and actuators, while supporting integration with SCADA and DCS platforms for centralized monitoring. By combining high-speed processing, deterministic control, and advanced diagnostics, this module optimizes turbine efficiency, reduces maintenance costs, and enhances operational safety—a cornerstone of GE’s legacy in industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210MACCH2AGG |

| Manufacturer | GE Fanuc |

| Product Type | Turbine Control Module |

| Platform | Mark VIe Speedtronic System |

| Input Voltage | 24 V DC ±10% (from rack power supply) |

| Communication Protocols | Modbus RTU, Ethernet/IP, GE Proficy HMI/SCADA |

| Control Functions | Speed regulation, load sharing, valve control, overspeed protection |

| Redundancy Support | Dual-channel hot-swappable redundancy |

| Physical Dimensions | 100 mm (H) × 100 mm (W) × 25 mm (D) |

| Weight | 1.0 kg |

| Operating Temperature | -40°C to +70°C |

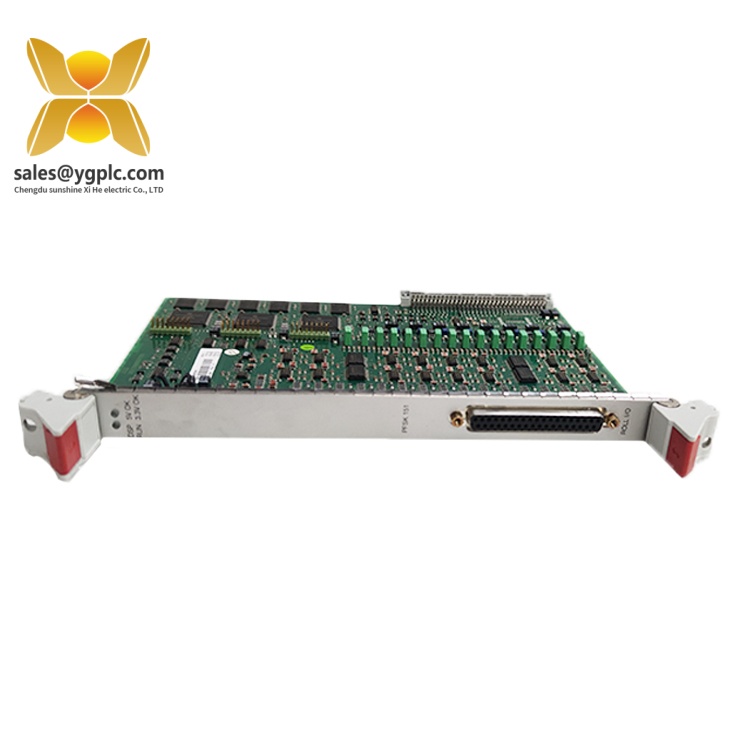

| Mounting | Rack-mounted in Mark VIe enclosure |

| Certifications | CE, UL, IEC 61131-3, API 670 |

Key Features and Advantages

Precision Turbine Control: The IS210MACCH2AGG executes advanced control algorithms to maintain turbine speed within ±0.1% of setpoint, ensuring seamless synchronization with power grids and optimizing energy efficiency. Its adaptive load-sharing capabilities balance power output across parallel turbines, reducing mechanical stress and extending equipment lifespan.

Hot-Swap Redundancy: Designed for high-availability systems, the module supports dual-channel redundancy, allowing a failed unit to be replaced without disrupting turbine operation. This feature is critical for uninterrupted power generation in utilities and industrial facilities.

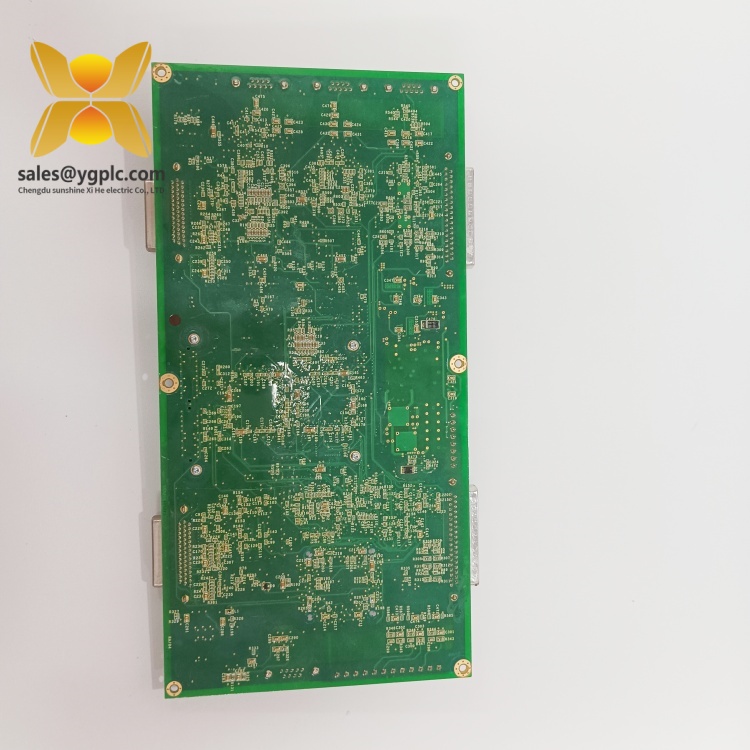

Robust Environmental Resilience: Engineered to withstand extreme temperatures, vibration, and electromagnetic interference, the IS210MACCH2AGG meets rigorous industrial standards, making it suitable for offshore platforms, refineries, and heavy machinery applications. Its conformal-coated circuitry protects against moisture and corrosive gases, enhancing reliability in harsh environments.

Integrated Diagnostics: Built-in LED indicators and self-test routines provide real-time feedback on module status, signal integrity, and thermal conditions. This proactive monitoring reduces troubleshooting time and supports predictive maintenance strategies, minimizing unplanned downtime.

Scalable System Integration: The module’s compatibility with GE’s Mark VIe I/O modules (e.g., analog/digital input/output cards) and communication gateways enables scalable control architectures. It integrates seamlessly with GE Proficy software for advanced visualization, data logging, and remote diagnostics.

Safety-Critical Design: Compliant with IEC 61508 functional safety standards, the IS210MACCH2AGG incorporates fail-safe logic and redundant communication pathways to ensure turbine protection under fault conditions. Its overspeed detection and emergency shutdown capabilities safeguard equipment and personnel in high-risk environments.

Application Areas

The GE IS210MACCH2AGG is indispensable for turbine control in industries where precision, reliability, and safety are paramount:

- Power Generation: Controls steam and gas turbines in thermal, combined-cycle, and hydroelectric power plants, managing speed, load, and synchronization with the grid. It optimizes fuel efficiency and reduces emissions by dynamically adjusting turbine parameters based on demand.

- Oil & Gas: Manages compression turbines in refineries, pipeline booster stations, and offshore platforms, ensuring stable operation of pumps, compressors, and safety interlocks. The module’s resilience to harsh conditions supports continuous uptime in remote or extreme environments.

- Heavy Industry: Deployed in large-scale manufacturing facilities, such as cement plants and steel mills, to regulate steam turbines driving generators, pumps, and ventilation systems. Its adaptive control logic accommodates fluctuating process demands while maintaining operational stability.

- Marine Propulsion: Integrates into marine gas turbine systems for propulsion and onboard power generation, providing precise speed control and redundancy critical for maritime applications.

Specific applications include:

- Overspeed Protection: Monitors turbine RPM and triggers emergency shutdowns to prevent catastrophic failure.

- Valve Positioning: Controls inlet and exhaust valves to optimize airflow and combustion efficiency.

- Load Rejection Handling: Maintains turbine stability during sudden load changes, such as grid disconnections or equipment trips.

Related Products

- IS210BPPCH1AEC Mark VIe Power Supply Module: Provides redundant 24 V DC power to the IS210MACCH2AGG and other Mark VIe components, ensuring continuous operation in critical systems.

- IS210TCCVH1A Turbine Vibration Monitoring Module: Works alongside the IS210MACCH2AGG to monitor shaft vibrations and bearing health, enabling predictive maintenance.

- IS210AAHAH2ADC Analog Input Module: Converts field sensor signals (e.g., temperature, pressure) into digital data for processing by the IS210MACCH2AGG.

- IS210TRBDH1A Terminal Base Module: Provides a structured interface for field wiring connections to the IS210MACCH2AGG, simplifying installation and maintenance.

- IS210CBLCH1A Communication Cable: Facilitates high-speed data transfer between the IS210MACCH2AGG and other Mark VIe modules, ensuring reliable system integration.

- IS210MACCH1AKH Mark VIe Controller: A predecessor model with similar functionality, suitable for retrofitting older turbine control systems.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS210MACCH2AGG, ensure the Mark VIe rack is properly grounded and ventilated to dissipate heat. Verify the power supply (24 V DC) and install redundant power modules for reliability. Mount the module in the rack using the provided hardware, aligning it with the backplane connectors. Connect field wiring (e.g., speed sensors, actuators) to the terminal base module, following GE’s wiring diagrams to minimize electromagnetic interference. Configure communication protocols (e.g., Modbus, Ethernet/IP) using GE’s Proficy software, ensuring compatibility with upstream SCADA systems.

Before installing the GE IS210MACCH2AGG, ensure the Mark VIe rack is properly grounded and ventilated to dissipate heat. Verify the power supply (24 V DC) and install redundant power modules for reliability. Mount the module in the rack using the provided hardware, aligning it with the backplane connectors. Connect field wiring (e.g., speed sensors, actuators) to the terminal base module, following GE’s wiring diagrams to minimize electromagnetic interference. Configure communication protocols (e.g., Modbus, Ethernet/IP) using GE’s Proficy software, ensuring compatibility with upstream SCADA systems.

Maintenance Suggestions:

- Routine Inspections: Monthly checks of LED indicators to verify module status and signal integrity. Use a multimeter to measure input/output voltages and currents, comparing readings against specifications.

- Cleaning and Cooling: Quarterly cleaning of the module’s vents and cooling fins to prevent dust accumulation, which can cause overheating. Ensure the rack’s cooling fans operate efficiently to maintain optimal temperatures.

- Redundancy Testing: Annually simulate a module failure to verify the redundant unit assumes control without disrupting turbine operation. Document test results for compliance and system reliability.

- Software Updates: Periodically update the module’s firmware using GE’s approved tools to address bugs, enhance functionality, and maintain cybersecurity. Back up configuration files before updates to avoid data loss.

- Spare Parts Management: Store spare IS210MACCH2AGG modules in a controlled environment (10–30°C, <50% humidity) to ensure rapid replacement during failures. Test spares every six months to confirm operational readiness.

Product Guarantee

Our company offers a 12-month quality warranty for the GE IS210MACCH2AGG, covering hardware defects under normal use. In the event of operational anomalies or functional failures, we provide prompt replacement services to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of the IS210MACCH2AGG and compatible spares, leveraging partnerships with GE Fanuc and authorized distributors. Our technical support team assists with installation, configuration, and troubleshooting, ensuring seamless integration into your turbine control system. With 17 years of expertise in industrial automation, we stand behind the reliability of our products and remain committed to supporting your operational continuity.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200TBCIH2CAA | Terminal Block Interface Module | IS200TBCIS2CCD

GE IS200TBCIH2CAA | Terminal Block Interface Module | IS200TBCIS2CCD

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200TDBTH6ACD | Terminal Board Module | IS200TVIBH2BBB

GE IS200TPROH1BBB | Mark VIe Turbine Protection Module | IS200TBCIH2CAA

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: