Description

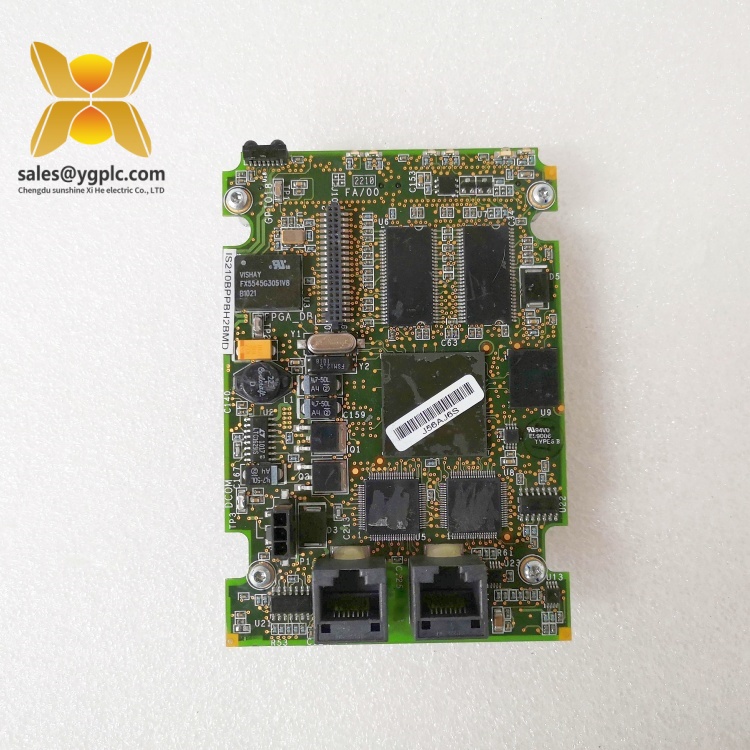

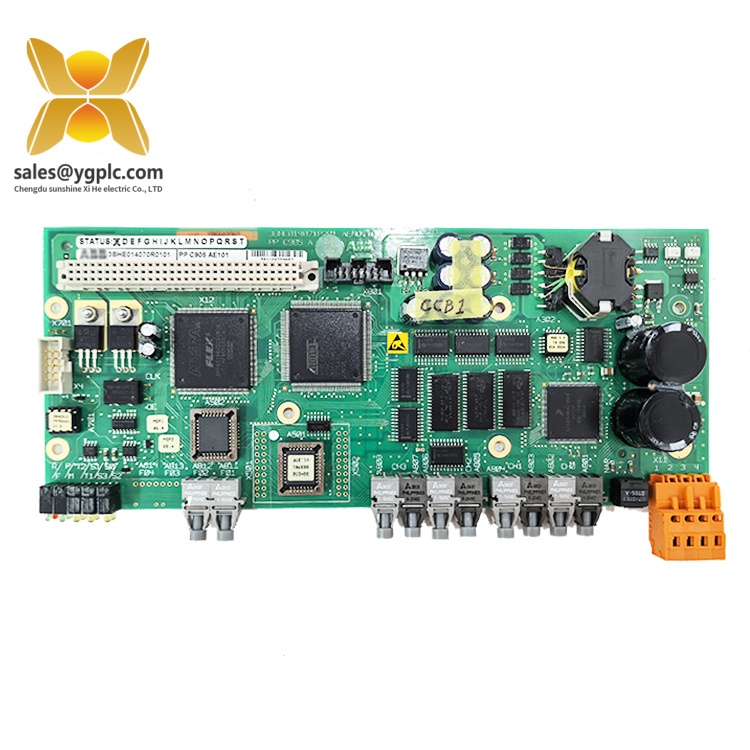

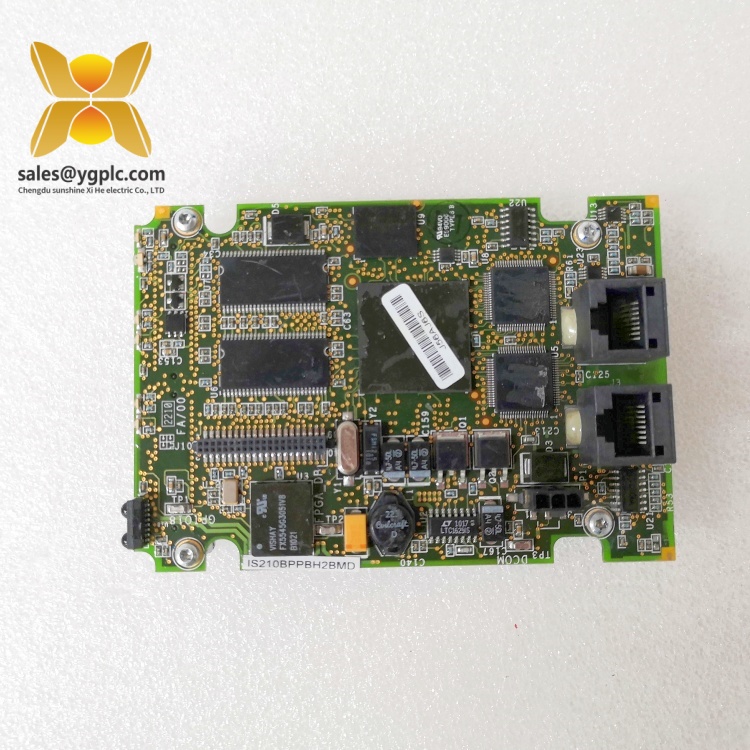

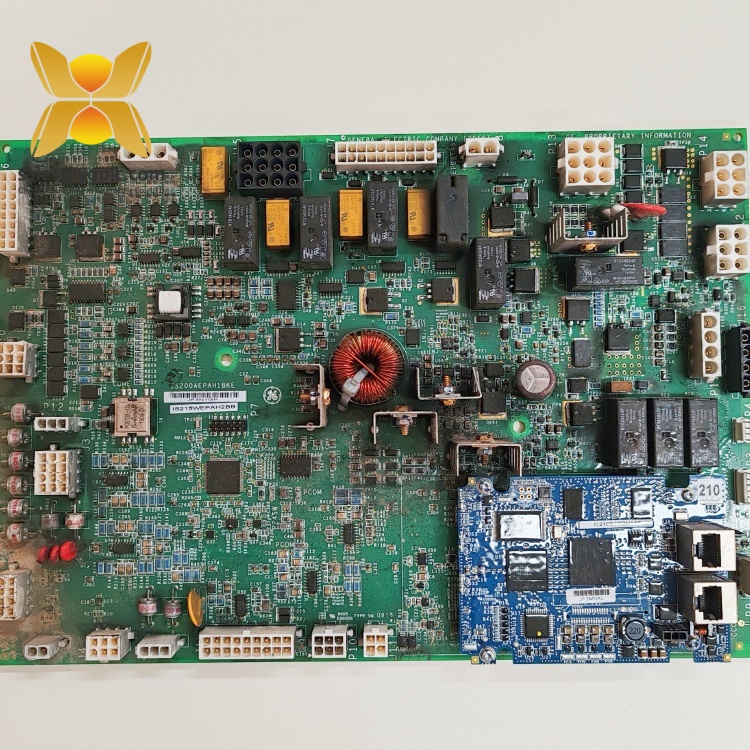

GE IS210BPPBH2BMD Mark VIe Power Supply Module

Product Overview

The GE IS210BPPBH2BMD is a high-reliability Power Supply Module designed as a critical component of GE’s Mark VIe distributed control system (DCS), tailored for industrial automation and turbine control applications. Engineered to deliver stable and redundant power to control modules in harsh industrial environments, this module ensures continuous operation of critical systems in power generation, oil & gas, and manufacturing sectors. As part of the IS210 Series, the IS210BPPBH2BMD integrates seamlessly with other Mark VIe components (e.g., control modules, I/O cards), providing a robust power infrastructure for mission-critical operations.

Featuring a rugged industrial design, the GE IS210BPPBH2BMD converts 100–240 V AC input to a regulated 24 V DC output, with built-in redundancy to ensure uninterrupted power supply. Its advanced power conditioning circuitry includes overvoltage, overcurrent, and thermal protection, safeguarding connected modules from electrical anomalies. The module’s hot-swappable design allows replacement without powering down the system, minimizing downtime during maintenance. With a wide operating temperature range (-40°C to +85°C) and compliance with industry standards (e.g., IEC 61131-2), the IS210BPPBH2BMD delivers reliable performance in challenging environments, from offshore platforms to heavy manufacturing facilities.

In automation ecosystems, the IS210BPPBH2BMD serves as the power backbone for Mark VIe control racks, ensuring stable power delivery to processors, communication modules, and I/O devices. Its compatibility with GE’s Proficy software suite enables real-time monitoring of power status and diagnostics, enhancing system visibility and maintenance efficiency. By combining high-efficiency power conversion with redundant architecture, this module supports the continuous operation of industrial systems, making it indispensable for sectors where downtime translates to significant losses.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210BPPBH2BMD |

| Manufacturer | GE |

| Product Type | Power Supply Module |

| Platform | Mark VIe |

| Input Voltage | 100–240 V AC, 50/60 Hz |

| Output Voltage | 24 V DC ±0.5% |

| Output Current | 10 A (continuous), 15 A (peak) |

| Efficiency | 90% typical |

| Redundancy | Hot-swappable redundant configuration |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 2.5 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Certifications | CE, UL, cUL |

Key Features and Advantages

Redundant Power Architecture: The IS210BPPBH2BMD supports hot-swappable redundant configurations, ensuring continuous operation even if one power supply fails. This eliminates single points of failure in critical systems, ideal for 24/7 industrial operations.

High-Efficiency Power Conversion: With 90% typical efficiency, the module minimizes energy loss and heat generation, reducing cooling requirements and operational costs. Its advanced circuitry maintains stable output under varying load conditions.

Comprehensive Protection Mechanisms: Built-in overvoltage, overcurrent, and thermal protection safeguard connected modules and the power supply itself, extending equipment lifespan and reducing maintenance needs.

Hot-Swap Capability: The module can be replaced without disrupting system operation, allowing maintenance during live operation. This feature is critical for minimizing downtime in time-sensitive industrial processes.

Rugged Industrial Design: Engineered to withstand extreme temperatures, vibration, and electromagnetic interference, the IS210BPPBH2BMD meets rigorous industrial standards, ensuring reliability in harsh environments.

Wide Input Voltage Range: Supporting 100–240 V AC input, the module adapts to diverse global power grids, reducing the need for region-specific adapters and enhancing installation flexibility.

Application Areas

The GE IS210BPPBH2BMD is essential for powering critical control systems in industries where reliability is non-negotiable:

- Power Generation: Powers turbine control systems in thermal, hydro, and renewable energy plants, ensuring stable power output and grid synchronization.

- Oil & Gas: Supports control modules in refineries, pipeline compression stations, and offshore platforms, enabling safe and efficient process operations.

- Manufacturing: Powers PLC and DCS systems in automotive, chemical, and food processing plants, maintaining production continuity and quality control.

- Water/Wastewater Treatment: Powers control systems for pumps, filters, and treatment processes, adapting to fluctuating operational demands.

Specific applications include:

- Turbine Control Systems: Powers Mark VIe modules that manage steam turbine speed, load, and safety interlocks in power plants.

- Process Automation: Supplies reliable power to control racks in chemical reactors and manufacturing lines, ensuring precise process regulation.

- Safety Instrumented Systems (SIS): Supports redundant power for safety-critical modules in oil & gas facilities, complying with industry safety standards.

Related Products

- IS210BPPCH1B Power Supply Module: A lower-current variant (5 A) for smaller control setups, compatible with the IS210BPPBH2BMD in redundant configurations.

- IS210MCCPH1B Motor Control Module: Works in tandem with the IS210BPPBH2BMD to control auxiliary motors in turbine systems.

- IS210TCCVH1A Turbine Vibration Module: Relies on the IS210BPPBH2BMD for power, monitoring shaft vibrations in rotating equipment.

- IS210MACCH1AKH Turbine Control Module: A core control module powered by the IS210BPPBH2BMD in Mark VIe systems.

- IS210ALGCH1B Algorithm Module: Integrates with the IS210BPPBH2BMD to execute advanced control logic in process automation.

- IS210CBLCH1A Communication Cable: Connects power supplies and modules, ensuring reliable signal transmission in Mark VIe racks.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS210BPPBH2BMD, ensure the Mark VIe rack is properly grounded and ventilated. Verify input voltage compatibility (100–240 V AC) and install redundant power cables for reliability. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect input power using shielded cables and terminate them in the rack’s power distribution block, following GE’s wiring guidelines to minimize electromagnetic interference.

Before installing the GE IS210BPPBH2BMD, ensure the Mark VIe rack is properly grounded and ventilated. Verify input voltage compatibility (100–240 V AC) and install redundant power cables for reliability. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect input power using shielded cables and terminate them in the rack’s power distribution block, following GE’s wiring guidelines to minimize electromagnetic interference.

Maintenance Suggestions:

- Routine Inspections: Monthly visual checks of LED indicators to verify power status and thermal conditions. Use a multimeter to measure output voltage and current, comparing readings against specifications.

- Cleaning and Cooling: Quarterly cleaning of module vents to prevent dust accumulation, especially in dusty environments. Ensure the rack’s cooling fans operate efficiently to maintain optimal temperatures.

- Redundancy Testing: Annually simulate a power supply failure to verify redundant operation, ensuring the backup module switches on correctly. Document test results for compliance.

- Spare Parts Management: Store spare IS210BPPBH2BMD modules in a controlled environment (10–30°C, <50% humidity) to ensure rapid replacement during failures. Test spares periodically to maintain functionality.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS210BPPBH2BMD, covering hardware defects under normal use. In the event of power output anomalies or functional failures, we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the IS210BPPBH2BMD and related spares. Our technical support team assists with installation, redundancy configuration, and troubleshooting, ensuring reliable power supply for your industrial control systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200SRTDH2ACB | Mark VIe RTD Input Module | IS200STCIH2A

GE IS200STAOH2AAA | Synchronizer Module (Gas Turbine Control) | IS200SPIDG1ABA

GE IS200EROCH1ABB | Exciter Regulator Output Module | IS200JPDDG1AAA

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

GE IS200JPDDG1AAA | Digital Input Module | IS200SPIDG1ABA

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IC697CPX928-FE Integrated protection device

GE IC697CPX935 Connecting module

GE IC697MDL671 Eddy current sensor

GE IC695CPU315-CD probe

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: