Description

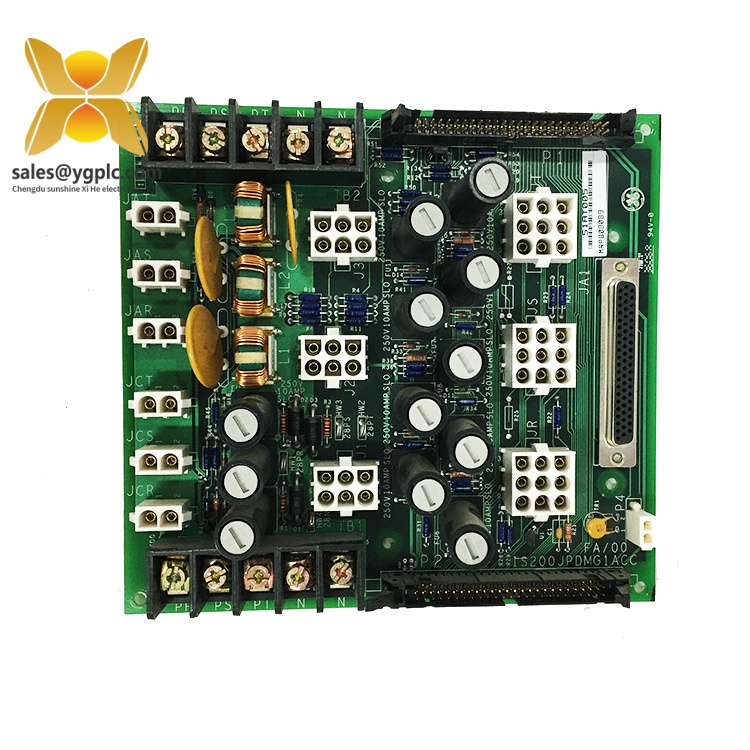

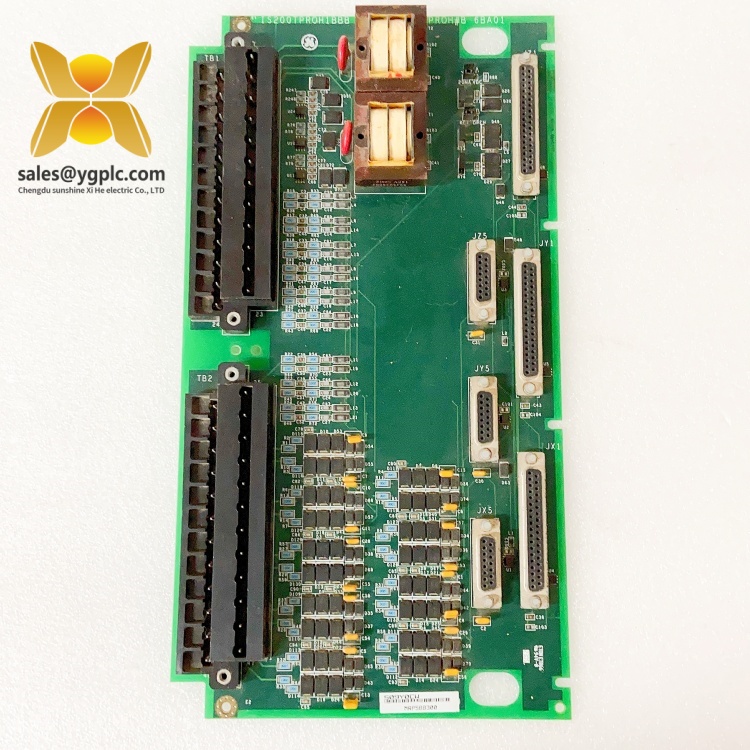

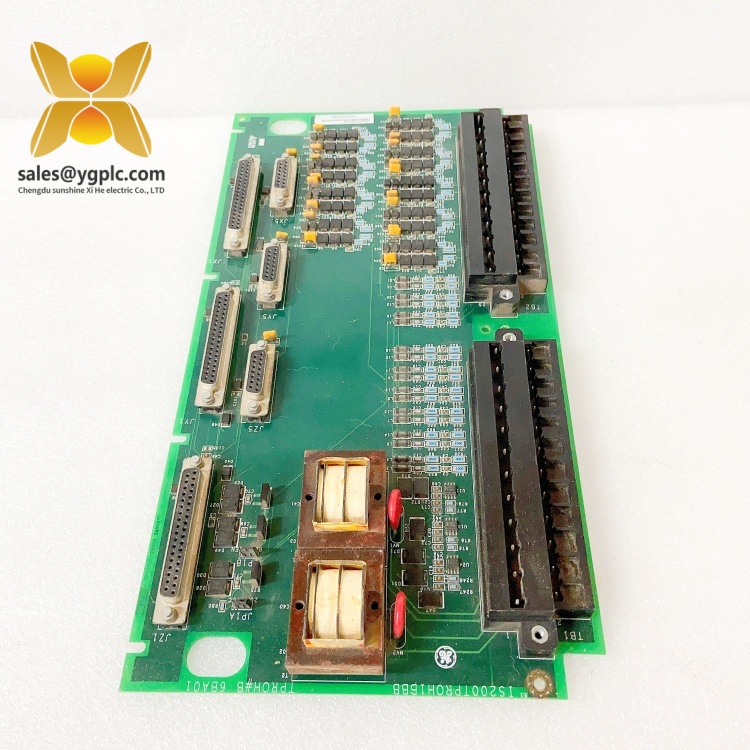

GE IS200TPROH1BBB Mark VIe Turbine Protection Module

Product Overview

The GE IS200TPROH1BBB is a high-reliability Turbine Protection Module designed as a critical component of GE’s Mark VIe distributed control system (DCS), specializing in safeguarding rotating equipment in power generation and industrial processes. Engineered to monitor and respond to critical turbine parameters, this module forms the backbone of protection systems for steam and gas turbines, ensuring safe operation by detecting anomalies and triggering protective actions. The IS200TPROH1BBB integrates seamlessly with other Mark VIe components, such as I/O modules and communication gateways, providing a comprehensive solution for turbine overspeed protection, vibration analysis, and emergency shutdown sequences.

Featuring a rugged industrial design, the GE IS200TPROH1BBB supports real-time data acquisition from speed probes, vibration sensors, and temperature transducers, processing signals to identify deviations from normal operating conditions. Its dual-core processor architecture enables rapid response to critical events, such as overspeed or excessive vibration, with built-in redundancy to maintain functionality during single-point failures. The module’s compatibility with GE’s Proficy software suite allows for remote configuration, diagnostics, and firmware updates, minimizing downtime and enhancing maintenance efficiency.

As a key element of the Mark VIe platform, the IS200TPROH1BBB bridges the gap between field instrumentation and the control system, ensuring reliable transmission of protection signals. Its modular design facilitates easy integration into existing turbine control systems, while compliance with industry standards (e.g., API 612, IEEE 1228) guarantees safety and reliability in mission-critical applications. By combining precision monitoring with robust fault tolerance, this module plays a vital role in preventing catastrophic equipment failures and maintaining operational continuity in power plants and heavy industries.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TPROH1BBB |

| Manufacturer | GE |

| Product Type | Turbine Protection Module |

| Platform | Mark VIe |

| Input Channels | 8 isolated channels (speed, vibration, temperature) |

| Processor | Dual-core 32-bit RISC, 100 MHz |

| Memory | 256 MB RAM, 512 MB flash storage |

| Communication | Ethernet (10/100 Mbps), RS-485, Profibus DP |

| Input Voltage | 24 V DC ±10% |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.9 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Certifications | CE, UL, API 612, IEEE 1228 |

Key Features and Advantages

Comprehensive Protection Functions: The IS200TPROH1BBB integrates overspeed protection, vibration monitoring, and thermal overload detection, providing multi-layered safeguards for turbines. Its configurable trip settings allow customization to match specific equipment requirements, enhancing operational flexibility.

Redundant Architecture: Dual-core processing and power supply redundancy ensure continuous operation even during component failures, reducing the risk of unplanned shutdowns. This design meets SIL 2 safety integrity requirements, making it suitable for high-risk applications.

High-Speed Signal Processing: With a 100 MHz processor, the module processes input signals in microseconds, enabling rapid response to critical events. This speed is essential for preventing overspeed conditions that could lead to turbine damage.

Advanced Diagnostics: Built-in self-diagnostic tools monitor module health, communication integrity, and signal validity, providing real-time alerts via LED indicators and the control system. This proactive approach reduces troubleshooting time and maintenance costs.

Rugged Industrial Design: The module’s metal enclosure and conformal-coated circuitry withstand harsh environments, including high temperatures, vibration, and electromagnetic interference, ensuring reliable performance in power plants and industrial facilities.

Seamless System Integration: Compatible with GE’s Mark VIe ecosystem, the IS200TPROH1BBB interfaces with I/O modules (e.g., IS200, IS210 series) and third-party systems via open protocols, simplifying integration into complex automation networks.

Application Areas

The GE IS200TPROH1BBB is strategically deployed in industries where turbine safety is non-negotiable:

- Power Generation: Protects steam turbines in thermal power plants, gas turbines in combined cycle facilities, and hydroelectric turbines, ensuring safe operation and grid stability.

- Oil & Gas: Monitors compressors and turbines in refineries, pipeline stations, and offshore platforms, preventing equipment damage from overspeed or mechanical failure.

- Industrial Process Control: Used in manufacturing plants for energy-intensive processes, such as chemical synthesis and metal refining, to safeguard turbines driving generators or mechanical systems.

- Marine Propulsion: Installed in marine gas turbines for large vessels, providing critical overspeed protection in dynamic sea conditions.

Specific applications include:

- Overspeed Protection Systems (OPS): Monitors turbine speed and triggers emergency shutdowns to prevent damage from excessive rotational speeds.

- Vibration Analysis: Processes vibration data to detect imbalance, misalignment, or bearing wear, enabling predictive maintenance.

- Thermal Management: Monitors bearing and stator temperatures, activating cooling systems or alarms to prevent overheating.

Related Products

- IS200TCTGG1A (Turbine Control Module): Works in tandem with the IS200TPROH1BBB to manage turbine speed and load, integrating control and protection functions.

- IS210TPROS1AAA (Turbine Protection Sensor Interface): Expands the IS200TPROH1BBB with additional sensor inputs, supporting complex turbine monitoring setups.

- IS200TBCHH1AA (Terminal Block Module): Provides a standardized wiring interface for field sensors, simplifying connections to the IS200TPROH1BBB.

- IS200PWRHH1AA (Power Supply Module): Ensures redundant power for the IS200TPROH1BBB, maintaining operation during power fluctuations.

- IS210COMMH1AA (Communication Module): Enables Ethernet connectivity for the IS200TPROH1BBB, supporting remote monitoring via SCADA systems.

- IS200VIBHH1AA (Vibration Input Module): Complements the IS200TPROH1BBB by providing high-precision vibration data acquisition.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS200TPROH1BBB, ensure the Mark VIe rack is properly grounded and ventilated. Verify sensor compatibility (speed probes, vibration transducers) and route shielded cables to minimize interference. Use GE’s Proficy software to configure trip thresholds, sensor types, and communication settings. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect power and sensor cables, following GE’s wiring guidelines to prevent signal degradation.

Before installing the GE IS200TPROH1BBB, ensure the Mark VIe rack is properly grounded and ventilated. Verify sensor compatibility (speed probes, vibration transducers) and route shielded cables to minimize interference. Use GE’s Proficy software to configure trip thresholds, sensor types, and communication settings. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect power and sensor cables, following GE’s wiring guidelines to prevent signal degradation.

Maintenance Suggestions:

- Routine Inspections: Quarterly checks of LED indicators and connection tightness. Use Proficy software to review diagnostic reports and ensure all channels function within specifications.

- Calibration: Annually calibrate speed and vibration inputs using certified test equipment to maintain measurement accuracy. Document calibration results for compliance.

- Firmware Updates: Periodically update the module’s firmware to incorporate safety patches and new features, following GE’s validated procedures to avoid system disruptions.

- Spare Parts Management: Store spare IS200TPROH1BBB modules in a static-free environment at room temperature, testing them annually to ensure functionality.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS200TPROH1BBB, covering hardware defects under normal use. In the event of unexpected failures, we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the IS200TPROH1BBB and related spares. Our technical support team assists with installation, configuration, and troubleshooting, delivering reliable solutions to maintain your turbine protection systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS200ERIOH1AAA | I/O Module for Mark VIe System | IS200PMCIH1AAA6BA00

GE IS200ERIOH1ABB | Mark VIe Remote I/O Module | IS200ISBBG2AAB

GE IS200EROCH1ABB | Exciter Regulator Output Module | IS200JPDDG1AAA

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

GE IS200JPDDG1AAA | Digital Input Module | IS200SPIDG1ABA

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200SPIDG1ABA | Power Interface Module | IS200SPIDG1ABA

GE IS200SPROH1AAB MRP663860 | Turbine Protection Relay Module | IS200SRTDH2ACB

GE IS200SRTDH2ACB | Mark VIe RTD Input Module | IS200STCIH2A

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: