Description

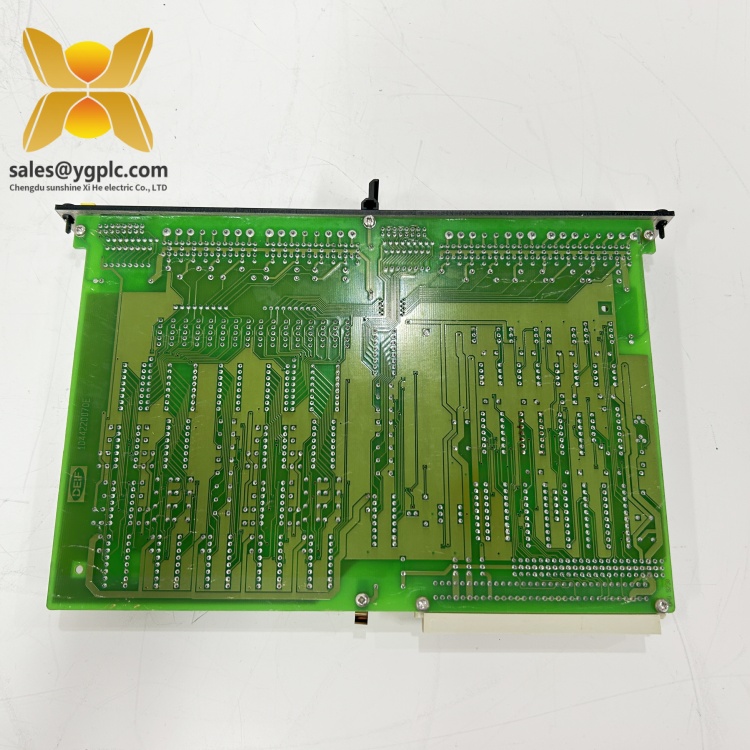

Product Overview

The DEIF OPM – 1 is a highly versatile and reliable output module designed to play a crucial role in various industrial control applications. As a part of DEIF’s comprehensive range of control system components, the DEIF OPM – 1 is engineered to provide precise control and management of output devices within power systems and industrial automation setups.

This module serves as a key interface between control systems and the equipment that needs to be actuated. It is mainly used for controlling a wide array of output devices such as valves, relays, and actuators. In power generation plants, for example, the OPM – 1 can be utilized to control the opening and closing of valves that regulate the flow of steam or fuel, ensuring efficient and stable power production. In industrial automation scenarios, it can drive relays to start or stop motors, facilitating smooth operation of production lines.

The DEIF OPM – 1 is part of the Delomatic multi – function system. This system is renowned for its ability to handle complex control tasks, and the OPM – 1 module contributes significantly to its functionality. With multiple output channels, each channel of the OPM – 1 can be individually configured and controlled. This flexibility allows it to meet diverse output requirements, whether it’s a simple on – off control for a digital device or a more complex analog control for a variable – speed actuator. It supports various signal types, including both analog signals such as voltage and current outputs, and digital signals like switch outputs. This wide signal compatibility makes it suitable for use in different types of industrial processes, from those that require precise analog control for maintaining specific process parameters to those that rely on digital signals for basic device activation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | OPM – 1 |

| Manufacturer | DEIF |

| Product Type | Output Module |

| Number of Output Channels | [X] (Typically multiple, e.g., 8 or 16 depending on version) |

| Signal Types Supported | Analog (Voltage: 0 – 10V, 4 – 20mA; Digital: TTL – compatible) |

| Communication Interface | [Common interfaces such as Modbus RTU for data exchange with other systems] |

| Power Supply Voltage | [e.g., 24V DC with a tolerance range of ±10%] |

| Operating Temperature Range | -20°C to +60°C |

| Humidity Range | 5 – 95% non – condensing |

| Dimensions (W x H x D) | [Provide specific dimensions, e.g., 100mm x 150mm x 50mm] |

| Weight | 750 gm |

| Protection Rating | [e.g., IP20 for protection against dust and limited protection against contact] |

OPM – 1

Key Features and Advantages

Multi – Channel and Configurable Outputs

The OPM – 1‘s multiple output channels offer great flexibility. Each channel can be set up independently, allowing for customized control strategies. For instance, in a building control system, one channel can be used to control the lighting in a specific area, while another can manage the operation of a ventilation fan. This independent configuration ensures that different devices can be controlled according to their specific requirements, optimizing energy consumption and system performance.

Wide Signal Compatibility

Supporting both analog and digital signals, the DEIF OPM – 1 can interface with a broad range of industrial equipment. In a chemical plant, it can use analog signals to control the flow rate of a chemical through a valve by adjusting the voltage or current output. At the same time, it can use digital signals to turn on or off a pump motor. This versatility eliminates the need for multiple specialized modules, reducing system complexity and cost.

Programmability

The module has a certain degree of programmability. Users can configure the operation and logic of the output channels based on their specific application needs. In a power distribution system, the OPM – 1 can be programmed to respond to certain electrical conditions. For example, if the voltage in a particular circuit drops below a set threshold, it can be programmed to activate a backup power source by sending appropriate control signals to the relevant relays.

Communication Capability

Equipped with a communication interface, such as Modbus RTU, the OPM – 1 can communicate with other devices or systems. This enables remote monitoring and control. In a large – scale industrial complex, operators can monitor the status of the output devices connected to the OPM – 1 from a central control room. They can also make changes to the module’s configuration or control settings remotely, improving operational efficiency and reducing the need for on – site intervention.

Alarm and Protection Functions

The OPM – 1 is designed with alarm and protection functions. In case of system abnormalities or malfunctions, it can trigger alarms. For example, if an output channel experiences an over – current condition, the module can send an alarm signal to the control system. It can also take protective measures, such as automatically shutting down the affected output to prevent damage to the connected equipment. This helps to enhance the reliability and safety of the overall industrial system.

OPM – 1

Application Areas

Power Generation

In power plants, whether they are fossil – fuel – based, nuclear, or renewable energy – powered, the DEIF OPM – 1 is used to control various aspects of power generation. It can control the operation of turbines by regulating the flow of steam or gas through valves. In a wind power plant, it can control the pitch of the wind turbine blades, optimizing the power output based on wind speed and direction. It also plays a role in controlling the distribution of power, ensuring that electricity is safely and efficiently transmitted to the grid.

Industrial Automation

In manufacturing industries, the OPM – 1 is an essential component in automated production lines. It can control the movement of robotic arms, the operation of conveyor belts, and the activation of various manufacturing equipment. In a food and beverage factory, it can control the filling and capping machines, ensuring accurate product packaging. In an automotive assembly plant, it can be used to control the movement of parts on the assembly line and the operation of robotic welding equipment.

Building Control

For building automation systems, the OPM – 1 is used to manage building services. It can control the heating, ventilation, and air – conditioning (HVAC) systems. For example, it can adjust the opening and closing of dampers in the ventilation system to maintain proper air quality and temperature. It can also control the lighting systems, turning lights on or off based on occupancy sensors or time schedules, contributing to energy conservation in buildings.

Marine Applications

On ships, the DEIF OPM – 1 is used for a variety of control tasks. It can control the operation of engines, regulating fuel injection and cooling systems. It can also manage the ship’s electrical distribution system, controlling the connection and disconnection of generators and loads. In addition, it can be used to control the ship’s navigation and communication equipment, ensuring safe and reliable operation at sea.

OPM – 1

Related Products

- DEIF SCM – 1: This is a control module within the Delomatic system. While the OPM – 1 focuses on output control, the SCM – 1 is more involved in overall system control and monitoring. They can be used together in a comprehensive power or industrial control setup, with the SCM – 1 sending control commands that the OPM – 1 then executes on the output devices.

- DEIF DGU (Generator Unit) Modules: These modules are related to power generation and management. The OPM – 1 can be integrated with DGU modules in a power plant or generator – based system. For example, the DGU modules can generate power, and the OPM – 1 can control the distribution of that power to different loads or equipment.

- DEIF CP (Control Panel) Components: Control panels provide the user interface for the Delomatic system. The OPM – 1 communicates with these control panels. Operators can view the status of the output devices controlled by the OPM – 1 on the control panel and make adjustments to the module’s settings through it.

- DEIF Communication Modules: There are specific communication modules in the DEIF product range that can enhance the communication capabilities of the OPM – 1. For example, if the OPM – 1‘s standard Modbus interface needs to be extended or if it needs to communicate with a different type of system, these communication modules can be used to bridge the gap.

- DEIF Sensor Modules: Sensor modules are used to collect data from the industrial environment. The data collected by these sensors can be used as input for the OPM – 1 to make control decisions. For example, a temperature sensor module can send temperature data, and based on this data, the OPM – 1 can control a cooling fan to maintain a proper temperature.

Installation and Maintenance

Installation Preparation

Before installing the DEIF OPM – 1, ensure that the power supply meets the specified requirements, such as the correct voltage and tolerance. Check the installation location for environmental conditions. It should be installed in an area with a temperature and humidity within the module’s operating range. Clean the installation surface to prevent dust or debris from interfering with the module’s operation. Mount the OPM – 1 securely, following the provided mounting instructions. Connect the input power cables correctly, ensuring proper grounding to protect against electrical malfunctions. Connect the communication cables to the appropriate devices, making sure the connections are tight and free from damage. Also, verify the compatibility of the devices that the OPM – 1 will be connected to in terms of signal types and communication protocols.

Maintenance Recommendations

Regularly inspect the OPM – 1 for any signs of physical damage, such as cracks in the casing or loose connections. Check the status indicators on the module to ensure normal operation. Periodically clean the module to prevent dust accumulation, which could affect its performance. Update the module’s firmware if new versions are available from DEIF. This can improve the module’s functionality, fix bugs, and enhance compatibility with other systems. Test the communication interface by sending and receiving test data to ensure proper data exchange. Check the output channels by connecting known loads and verifying that the module is providing the correct control signals. In case of any alarms or malfunctions, refer to the module’s manual to troubleshoot and resolve the issues promptly.

OPM – 1

Product Warranty

We, as a leading enterprise in the industrial control industry with 17 years of experience, are committed to providing high – quality products and services. We offer a one – year quality warranty for the DEIF OPM – 1 module. This warranty covers hardware failures caused by non – human factors. During the warranty period, if the OPM – 1 shows any performance anomalies or functional failures, we will replace the module free of charge. For discontinued models or in case of urgent needs, our extensive global supply chain network enables us to quickly respond to customers’ requests for scarce spare parts. We strive to ensure that our customers’ industrial systems can operate continuously and stably, backed by our reliable product support and service.

Woodward 8237-1369 governor

Woodward 8237-1600 Input module

ABB DSDP140B 57160001-ACX Logic controller

ABB SC520 3BSE003816R1 Control panel

ABB CS513 3BSE000435R1 Double output

ABB UAD149A0011 Servo valve

ABB NAIO-03 Optical fiber interface board

ABB PM633 Acquisition card

ABB REF542PLUS Gas turbine card

ABB UFC718AE101 HIEE300936R0101 Enhanced intelligent communication module

GE IS420UCSBH3A Analog output module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: