Description

Product Overview

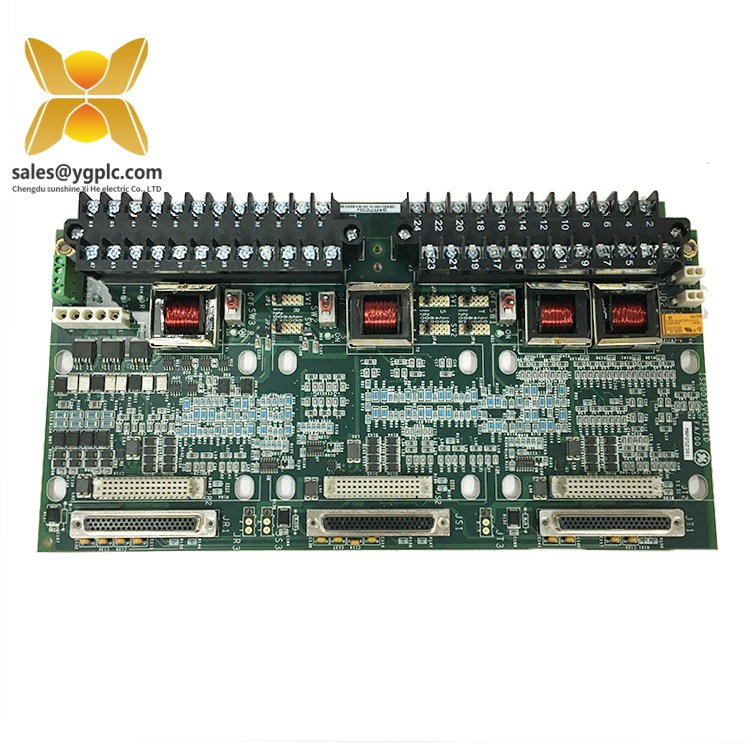

The ALSTOM DSI1817 TRVC062335000 CP00003934 is a high-performance digital control module designed for critical industrial applications, specifically engineered for integration with ALSTOM’s advanced automation systems. As a key component of ALSTOM’s modular control architecture, this module serves as a versatile interface for real-time data acquisition, process monitoring, and closed-loop control in complex industrial environments.E-mail :sales@ygplc.com.

The DSI1817 TRVC062335000 CP00003934 is optimized for precision and reliability, supporting a wide range of input/output (I/O) configurations to interface with sensors, actuators, and other field devices. Its core function is to translate analog and digital signals into actionable commands, ensuring seamless coordination between higher-level control systems and physical processes. Equipped with a robust 32-bit processor and dedicated firmware, the module supports advanced control algorithms, including PID regulation and predictive analytics, making it ideal for applications requiring high dynamic response and tight tolerance control.

Part of ALSTOM’s comprehensive automation portfolio, the DSI1817 TRVC062335000 CP00003934 is designed for modular integration into systems ranging from power generation plants to industrial manufacturing lines. It acts as a bridge between programmable logic controllers (PLCs), human-machine interfaces (HMIs), and field devices, enabling centralized monitoring and decentralized control. By combining high-speed data processing with scalable connectivity, this module enhances the efficiency, reliability, and safety of industrial operations, reducing downtime and minimizing energy consumption in critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DSI1817 TRVC062335000 CP00003934 |

| Manufacturer | ALSTOM |

| Product Type | Digital Control Module |

| Series Compatibility | ALSTOM Modular Control Platforms |

| I/O Configuration | 16 digital inputs, 16 digital outputs (expandable via add-on modules) |

| Input Voltage | 24 V DC (±10%) |

| Power Consumption | ≤15 W (typical) |

| Communication Protocols | PROFINET, EtherCAT, Modbus TCP/IP, OPC UA |

| Signal Types | Digital: 24 V DC dry contact; Analog: 4-20 mA (optional with expansion modules) |

| Processing Speed | 100 μs per I/O cycle |

| Isolation | 500 V DC between field and system |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5%–95% non-condensing |

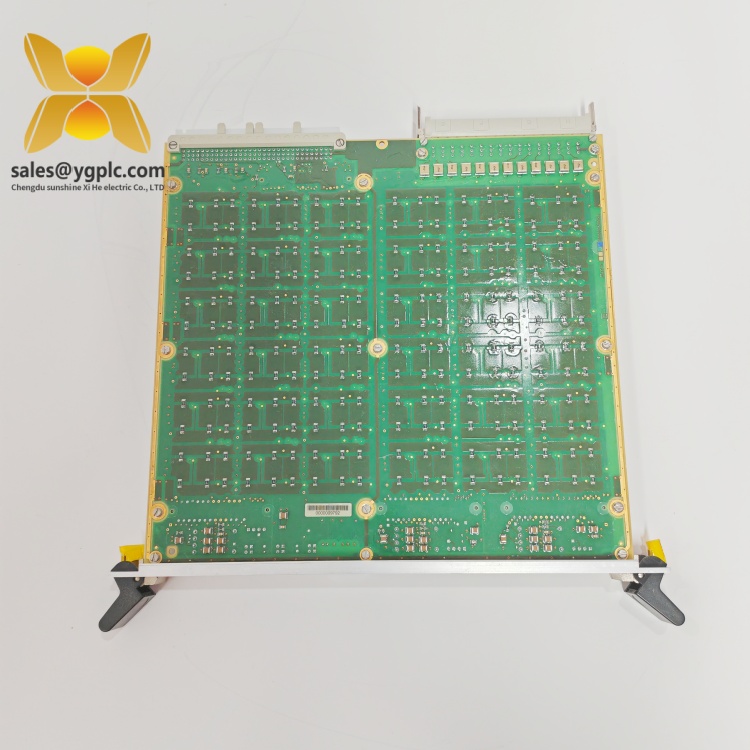

| Physical Dimensions | 180 mm (W) × 120 mm (H) × 80 mm (D) |

| Mounting Method | DIN-rail (35 mm) or panel mount |

| Protection Class | IP20 (front panel), IP54 with optional enclosure |

| Diagnostic Features | LED indicators for power, communication, and channel status; self-diagnostic routines for fault detection |

DSI1817 TRVC062335000 CP00003934

Main Features and Advantages

High-Speed Data Processing

The ALSTOM DSI1817 TRVC062335000 CP00003934 delivers exceptional processing speed, with a 100 μs cycle time for I/O operations, ensuring real-time responsiveness in fast-paced industrial environments. Its 32-bit processor supports parallel execution of multiple control tasks, enabling simultaneous monitoring of critical parameters and rapid adjustment of process variables. For example, in a power plant’s steam turbine control system, the module can analyze vibration sensor data and adjust valve positions within milliseconds to maintain optimal operating conditions.

Flexible I/O Expansion

With 16 configurable digital I/O channels and support for expansion modules, the DSI1817 TRVC062335000 CP00003934 adapts to diverse application requirements. Additional analog I/O modules can be integrated to handle 4-20 mA signals from pressure transmitters or flow meters, while digital modules support communication with solenoid valves and proximity sensors. This flexibility reduces the need for multiple specialized controllers, streamlining system design and reducing hardware costs.

Robust Industrial Design

Engineered for harsh environments, the module features a rugged enclosure that resists dust, moisture, and electromagnetic interference (EMI). Its wide operating temperature range (-20°C to +60°C) and high vibration tolerance (up to 5 g, 10–200 Hz) make it suitable for use in power plants, refineries, and offshore platforms. The hot-swappable design allows for module replacement without system shutdown, minimizing downtime during maintenance.

Advanced Communication Capabilities

The DSI1817 TRVC062335000 CP00003934 supports multiple industrial communication protocols, including PROFINET and EtherCAT, enabling seamless integration with higher-level systems such as PLCs, SCADA, or MES platforms. This connectivity allows for remote monitoring, predictive maintenance, and optimization of overall equipment effectiveness (OEE). For instance, in a smart factory setup, the module can transmit real-time process data to a central server, enabling proactive adjustments to production schedules and energy consumption.

DSI1817 TRVC062335000 CP00003934

Comprehensive Diagnostic and Safety Features

Built-in self-diagnostic functions continuously monitor sensor signals, power supply stability, and thermal conditions, alerting operators to potential issues through digital outputs or network messages. The module also supports safety protocols such as STO (Safe Torque Off), ensuring compliance with ISO 13849 safety standards. These features enhance system reliability and protect personnel and equipment in emergency situations, making it an ideal choice for safety-critical applications like chemical processing and automotive assembly lines.

Application Areas

Power Generation

In thermal and nuclear power plants, the ALSTOM DSI1817 TRVC062335000 CP00003934 controls steam turbine operations, monitoring parameters such as temperature, pressure, and rotational speed. It adjusts valve positions to maintain optimal power output and coordinates with generator control systems for grid synchronization. For renewable energy installations, the module manages wind turbine pitch control and solar panel tracking systems, ensuring maximum energy capture under varying environmental conditions.

Oil and Gas Processing

In upstream and downstream oil and gas facilities, the module interfaces with distributed control systems (DCS) to monitor pipeline pressures, regulate pump operations, and manage emergency shutdown sequences. Its high-speed processing capabilities enable rapid response to conditions, such as leaks or overpressure events, minimizing environmental risks and production losses. In offshore platforms, the DSI1817 TRVC062335000 CP00003934 withstands harsh saltwater environments while maintaining reliable control over drilling and production processes.

Industrial Manufacturing

In automotive and consumer goods manufacturing, the module coordinates conveyor systems, robotic arms, and quality control sensors. It ensures precise motion control in assembly lines and tracks production metrics for OEE optimization. For example, in a food packaging plant, the DSI1817 TRVC062335000 CP00003934 can synchronize labeling machines with product flow while detecting faulty seals via vision systems, reducing waste and improving product quality.E-mail :sales@ygplc.com.

Water and Wastewater Treatment

For water purification and wastewater treatment plants, the module controls chemical dosing systems, monitors pH levels, and manages pump stations. It ensures consistent water quality by adjusting treatment processes in real-time based on sensor feedback. In wastewater treatment facilities, the DSI1817 TRVC062335000 CP00003934 automates sludge dewatering processes while alerting operators to clogged filters or equipment malfunctions, ensuring compliance with environmental regulations.

DSI1817 TRVC062335000 CP00003934

Mining and Heavy Machinery

In mining operations, the module manages conveyor belts, crushing equipment, and ventilation systems, optimizing energy usage and reducing downtime. Its robust design allows it to operate in dusty, high-vibration environments typical of mining sites. For heavy machinery such as excavators and loaders, the DSI1817 TRVC062335000 CP00003934 controls hydraulic systems, ensuring smooth and safe load handling while minimizing fuel consumption.

Related Products

- ALSTOM DSI1818 TRVC062336000 CP00003935: An upgraded version with 32 digital I/O channels and advanced diagnostic capabilities, suitable for complex multi-axis control systems.

- ALSTOM DSI1819 TRVC062337000 CP00003936: A mixed-signal module supporting both digital and analog I/O, complementary to the DSI1817 TRVC062335000 CP00003934 for hybrid control applications.

- ALSTOM C300 Controller: The primary control platform for ALSTOM’s modular systems, providing real-time processing and communication with the DSI1817 TRVC062335000 CP00003934.

- ALSTOM PM864AK01 3BSE01816R1: A high-performance processor module from ABB, compatible with the DSI1817 TRVC062335000 CP00003934 in hybrid automation setups requiring multi-vendor integration.

- ALSTOM VT-HNC100-1-23M-08-P-0: A hydraulic control module that pairs with the DSI1817 TRVC062335000 CP00003934 for applications combining digital control with hydraulic actuation.

- ALSTOM HMI 500: A touchscreen interface for programming and monitoring the DSI1817 TRVC062335000 CP00003934, offering intuitive system diagnostics and configuration.

- ALSTOM CC-PUIO31: A universal I/O module from Honeywell, compatible with the DSI1817 TRVC062335000 CP00003934 in distributed control systems requiring multi-brand integration.

Installation and Maintenance

Installation Preparations:

Before installing the ALSTOM DSI1817 TRVC062335000 CP00003934, ensure the control system is powered off and the DIN rail is securely mounted. Verify the 24 V DC power supply meets the module’s requirements (18–31.2 V DC) and use shielded cables to minimize EMI. Configure the module’s communication parameters (e.g., IP address, PROFINET device name) using ALSTOM’s configuration software, ensuring compatibility with the host controller. Connect field devices to the removable screw terminals, following the wiring diagram provided in the user manual to avoid polarity errors.E-mail :sales@ygplc.com.

Before installing the ALSTOM DSI1817 TRVC062335000 CP00003934, ensure the control system is powered off and the DIN rail is securely mounted. Verify the 24 V DC power supply meets the module’s requirements (18–31.2 V DC) and use shielded cables to minimize EMI. Configure the module’s communication parameters (e.g., IP address, PROFINET device name) using ALSTOM’s configuration software, ensuring compatibility with the host controller. Connect field devices to the removable screw terminals, following the wiring diagram provided in the user manual to avoid polarity errors.E-mail :sales@ygplc.com.

Maintenance Recommendations:

Regularly inspect the module for physical damage, loose connections, or dust accumulation, particularly in high-humidity environments. Clean the enclosure with a dry cloth and check LED indicators for fault signals—e.g., a red light may indicate a communication failure or power irregularity. Update the firmware periodically to access the latest control algorithms and security patches. For critical applications, schedule annual checks of I/O modules and sensor calibration to ensure long-term accuracy and reliability. In case of persistent issues, contact our technical support team for remote troubleshooting or replacement guidance.

Regularly inspect the module for physical damage, loose connections, or dust accumulation, particularly in high-humidity environments. Clean the enclosure with a dry cloth and check LED indicators for fault signals—e.g., a red light may indicate a communication failure or power irregularity. Update the firmware periodically to access the latest control algorithms and security patches. For critical applications, schedule annual checks of I/O modules and sensor calibration to ensure long-term accuracy and reliability. In case of persistent issues, contact our technical support team for remote troubleshooting or replacement guidance.

DSI1817 TRVC062335000 CP00003934

Product Assurance

Our company provides a one-year quality warranty for the ALSTOM DSI1817 TRVC062335000 CP00003934, covering hardware failures due to non-human factors. During the warranty period, we will promptly replace any defective components at no additional cost. For discontinued models or urgent requirements, our global supply chain network leverages extensive inventory and strategic partnerships to fulfill orders within tight timelines, even for hard-to-find spare parts. With 17 years of expertise in industrial control distribution, we ensure that your systems benefit from the DSI1817 TRVC062335000 CP00003934’s advanced capabilities, backed by our commitment to reliable service and technical support. Trust us to deliver solutions that enhance your operational efficiency and maintain the highest standards of industrial automation.

Whatsapp:+86 18859254943.

Whatsapp:+86 18859254943.

ALSTOM CMP1838 TRVCO62345000 CP00005202 Motion controller

ALSTOM DSI1817 TRVC062335000 CP00003934 System-wide spare parts

ALSTOM I/OBE2 12004-104-00 V1.0.0 ITCC controller

ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 Fault tolerant control system

ALSTOM POS1846 TRVC062333000 CP00000310 Digital input module

ALSTOM STO1726KO1 Safety system module

ALSTOM VIIB16-C 12011-105-00 V1.0.0 Network communication card

ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0 Digital oscilloscope

ALSTOM VPS 12004-102-03 V1.0.0 DI connection base plate

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: