Description

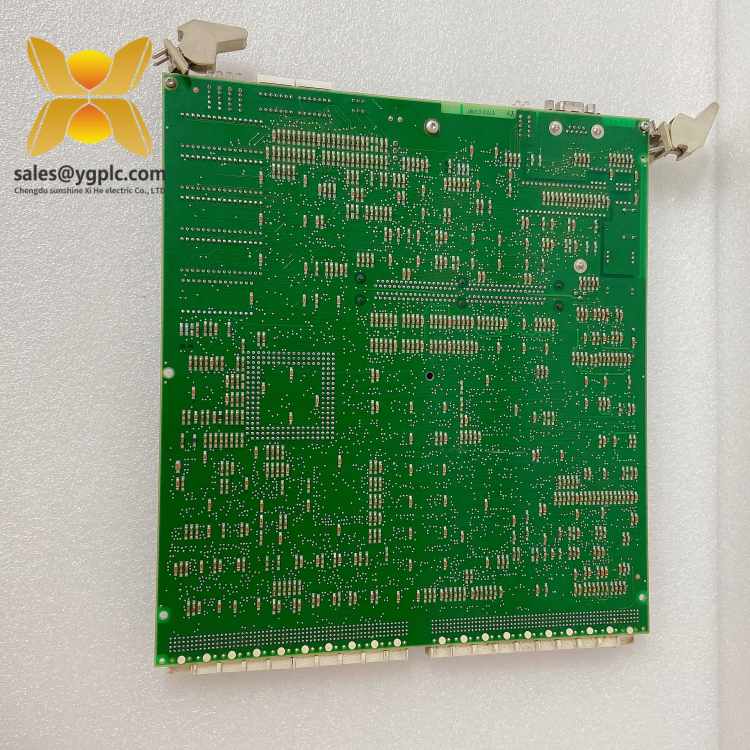

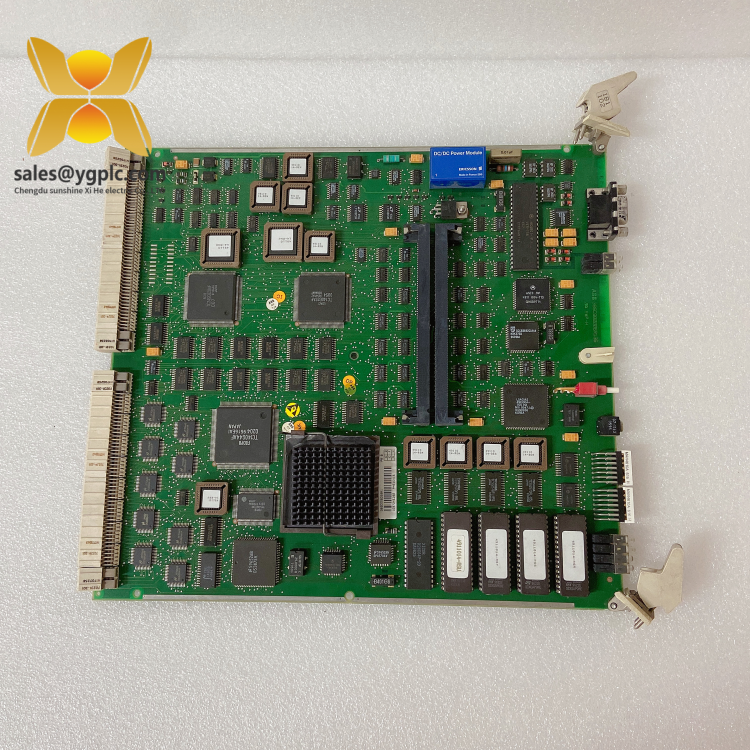

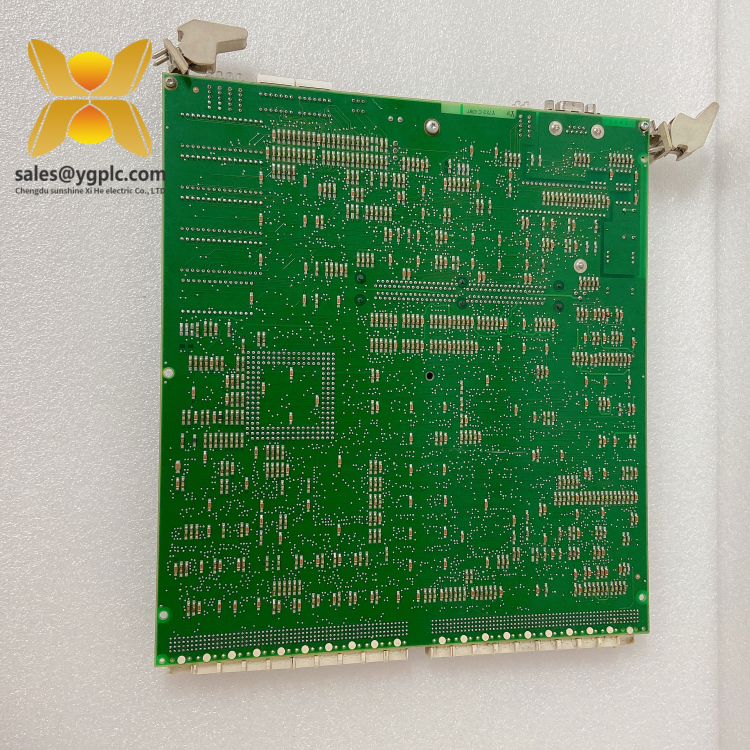

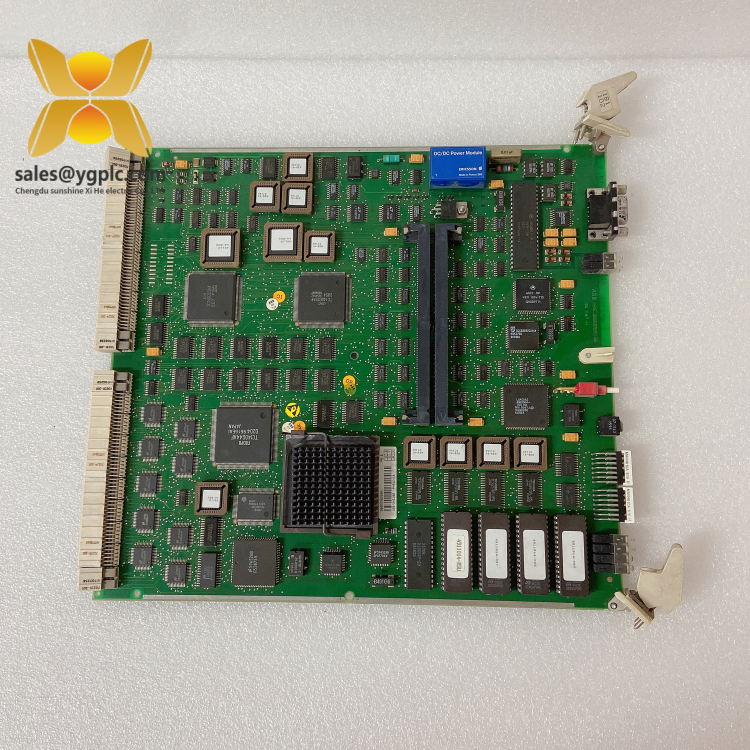

Product Overview: ABB PM510V16

ABB PM510V16 is a high-performance industrial controller designed for mid-range automation applications, combining robust processing capabilities with flexible scalability. Engineered for reliability in demanding environments, this module supports real-time control, data processing, and seamless integration with ABB’s AC500 PLC system. Ideal for industries requiring balanced performance and cost efficiency, it excels in factory automation, process control, and building management systems.

Technical Specifications — ABB PM510V16

| Parameter | Specification |

|---|---|

| Operating Voltage | 24V DC ±10% |

| Power Consumption | ≤25W (typical operation) |

| Processor | 32-bit RISC CPU, 800 MHz |

| Memory | 64MB SDRAM + 32MB flash storage |

| I/O Capacity | Expandable to 256 digital/128 analog points |

| Communication Ports | 2x Ethernet (10/100 Mbps), 1x RS485 |

| Operating Temperature | -25°C to +70°C |

| Certifications | CE, UL, cUL, RoHS |

ABB PM510V16

Related products: ABB PM510V16

- ABB PM510V14: Compact variant for small-scale systems.

- ABB PM510V18: High-end model with enhanced processing power.

- ABB DI810/DO810: Digital I/O modules for expanded connectivity.

- ABB AC500-eCo: Compatible PLC system for distributed control.

Main features and advantages: ABB PM510V16

- Select I/O Flexibility: Supports ABB’s Select I/O system, allowing late-stage I/O configuration to adapt to project changes efficiently .

- High-Speed Processing: 800 MHz CPU ensures rapid response to real-time control demands.

- Wide Temperature Range: Operates reliably from -25°C to +70°C, suitable for extreme industrial environments .

- Modular Expansion: Scalable I/O options accommodate growing system requirements.

- Dual Ethernet Redundancy: Ensures continuous communication in critical applications.

- User-Friendly Programming: Utilizes CODESYS-based software for intuitive logic development.

ABB PM510V16

Installation and maintenance: ABB PM510V16

- Installation:

- Mount on 35mm DIN rails with integrated clips; secure wiring via front-terminal blocks.

- Configure I/O modules through software before powering up.

- Maintenance:

- Clean ventilation slots quarterly to prevent dust accumulation.

- Verify cable connections biannually for corrosion or looseness.

- Update firmware regularly via ABB’s official tools for optimal performance.

ABB PM510V16

Application fields: ABB PM510V16

- Manufacturing: Assembly line automation, quality inspection systems, and semiconductor fabrication (e.g., PVD/CVD reactor control) .

- Energy & Utilities: Power plant monitoring, renewable energy management, and smart grid applications.

- Water Treatment: Pump control, filtration processes, and chemical dosing systems.

- Logistics: Conveyor systems, warehouse automation, and material handling equipment.

- Building Automation: HVAC control, lighting management, and energy-efficient facility operations.

Product guarantee: ABB PM510V16

- Warranty: 12-month limited warranty covering material defects .

- Technical Support: ABB-certified engineers provide pre-sales consultation and post-installation troubleshooting.

- Spare Parts: Fast delivery of genuine components to minimize downtime.

- Software Updates: Free firmware upgrades to enhance functionality and security.

For detailed inquiries or customized solutions, contact us via WhatsApp +86 18859254943 or visit www.ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: