Description

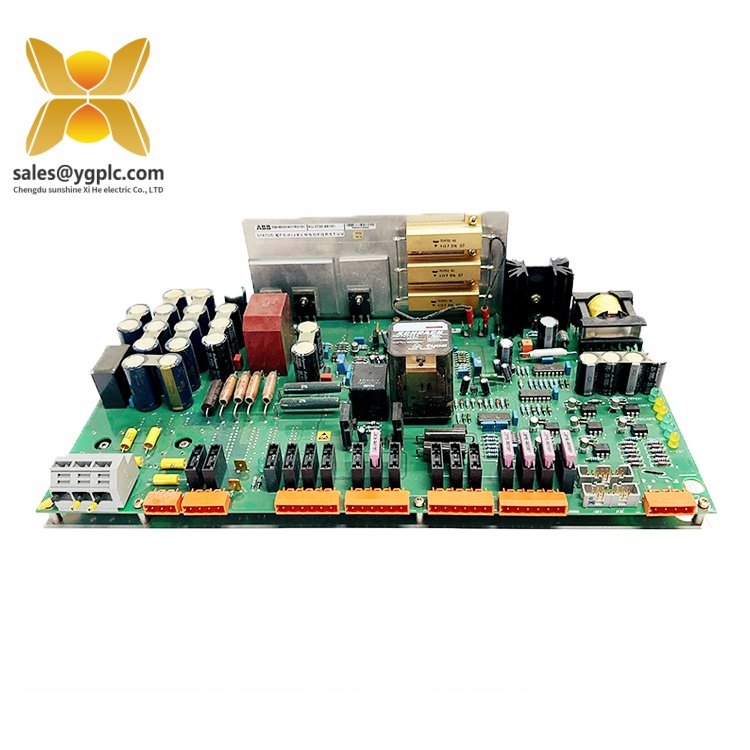

Product Overview :ABB 3ASC25H219B DATX133

Technical Specifications :ABB 3ASC25H219B DATX133

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3ASC25H219B DATX133 |

| Manufacturer | ABB |

| Product Type | Process Automation Module |

| Input Voltage | 24V DC ±10% |

| Communication Protocols | Profibus DP, Modbus RTU, Ethernet/IP |

| Physical Dimensions | 150mm x 100mm x 50mm |

| Weight | 0.6 kg |

| Mounting Type | DIN rail (TS35/7.5 or TS35/15) |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5–95% non-condensing |

| Protection Rating | IP20 |

| Country of Origin | Sweden |

Key Features and Advantages :ABB 3ASC25H219B DATX133

Seamless Integration with ABB Ecosystem: As part of the AC 800M system, the 3ASC25H219B DATX133 integrates seamlessly with ABB’s portfolio of I/O modules, drives, and HMIs. This ecosystem compatibility streamlines system design, reduces configuration time, and enhances overall operational efficiency.

3ASC25H219B DATX133

Application Areas :ABB 3ASC25H219B DATX133

- Power Generation: Used in thermal, hydro, and wind power plants to monitor and control turbine operations, generator parameters, and grid synchronization. The module’s redundancy feature ensures stable power output even in fluctuating grid conditions.

- Oil & Gas: Integrates with upstream and downstream systems in refineries, pipelines, and offshore platforms, enabling real-time monitoring of pressure, flow, and temperature in critical processes. Its Profibus DP compatibility facilitates connection to field instruments in hazardous areas.

- Chemical Processing: Manages complex batch processes in chemical plants, ensuring accurate control of reaction parameters and safety interlocks. The module’s Ethernet/IP support enables integration with MES and ERP systems for end-to-end process optimization.

- Water and Wastewater Treatment: Controls pumps, valves, and filtration systems in water treatment plants, ensuring compliance with regulatory standards. Its Modbus RTU interface simplifies connection to legacy SCADA systems commonly used in utility applications.

- Manufacturing: Enhances productivity in smart factories by connecting PLCs, robotics, and conveyor systems to a centralized control platform. The module’s real-time data capabilities support predictive maintenance and lean manufacturing initiatives.

Related Products :ABB 3ASC25H219B DATX133

- ABB 3BSE018166R1 (PM866AK01): A processor module for the AC 800M system, 配套使用 with the 3ASC25H219B DATX133 to execute control algorithms and manage system coordination.

- ABB 3ASC25H220B (DATX135): An upgraded version with enhanced Ethernet capabilities, offering faster data transfer rates and support for modern industrial IoT protocols.

- ABB 3BSE020852R1 (DI810): A digital input module that works alongside the 3ASC25H219B DATX133 to capture discrete signals from switches and sensors.

- ABB 3BSE020853R1 (DO810): A digital output module for controlling actuators and relays, complementing the 3ASC25H219B DATX133 in closed-loop control systems.

- ABB 3BSE018287R1 (AI810): An analog input module for converting sensor signals into digital data, expanding the 3ASC25H219B DATX133’s data acquisition capabilities.

- ABB 3BSE018288R1 (AO810): An analog output module for precise control of valves and drives, integrating smoothly with the 3ASC25H219B DATX133 in process automation loops.

- ABB 3HAC025208-001 (DSQC607): A robot communication module that enables the 3ASC25H219B DATX133 to interface with ABB robots in manufacturing cells.

3ASC25H219B DATX133

Installation and Maintenance :ABB 3ASC25H219B DATX133

Before installing the 3ASC25H219B DATX133, ensure the control cabinet is properly grounded and ventilated to meet the module’s environmental requirements. Verify that the 24V DC power supply is stable and within the specified voltage range. Mount the module on a DIN rail using the provided clips, ensuring secure mechanical fixation. Connect the power cables to the terminal blocks, following ABB’s wiring guidelines, and establish communication links via Profibus, Modbus, or Ethernet cables, depending on the application’s protocol requirements.

- Routine Inspections: Conduct monthly visual checks to ensure the module’s LED indicators are functioning correctly and there are no signs of physical damage or overheating. Clean the module’s surface with a dry cloth to prevent dust accumulation that could affect heat dissipation.

- Firmware Updates: Periodically update the module’s firmware using ABB’s Control Builder M software to access new features, security patches, and performance improvements. Back up existing configurations before initiating firmware updates to avoid data loss.

- Redundancy Testing: Perform quarterly tests of the dual communication channels to ensure failover functionality operates as expected. Simulate primary channel failures to verify seamless switching to the backup channel and monitor system recovery time.

- Connector Maintenance: Inspect communication and power connectors annually for signs of corrosion or loose connections. Re-tighten terminal blocks and replace damaged cables promptly to maintain reliable signal transmission.

3ASC25H219B DATX133

Product Warranty :ABB 3ASC25H219B DATX133

Note: All product names, logos, and trademarks belong to their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to ABB’s official manuals for detailed installation and operation instructions.

ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010 Digital output module

ABB 500PSM02 1MRB150015R1 AD-272.100.20-01 AZ:C Control system power supply

ABB DSPU131 3BSE000355R1 Inverter operating panel

ABB GDD471A001 AI/AO/DI/DO module

ABB UAD149A0011 Servo valve

ABB 3BHE023784R2530 PPD113B01-25-111000 redundancy

ABB 3BHE032025R0101 PCD235A101 Network communication

ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 I/O board

ABB SC520 3BSE003816R1 Control panel

ABB PPD113B01-10-150000 3BHE023784R1023 Gas turbine card

ABB UDD406A FIM card

ABB PPC905AE101 3BHE014070R0101 Communication input interface component

ABB UFC718AE101 HIEE300936R0101 Enhanced intelligent communication module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: