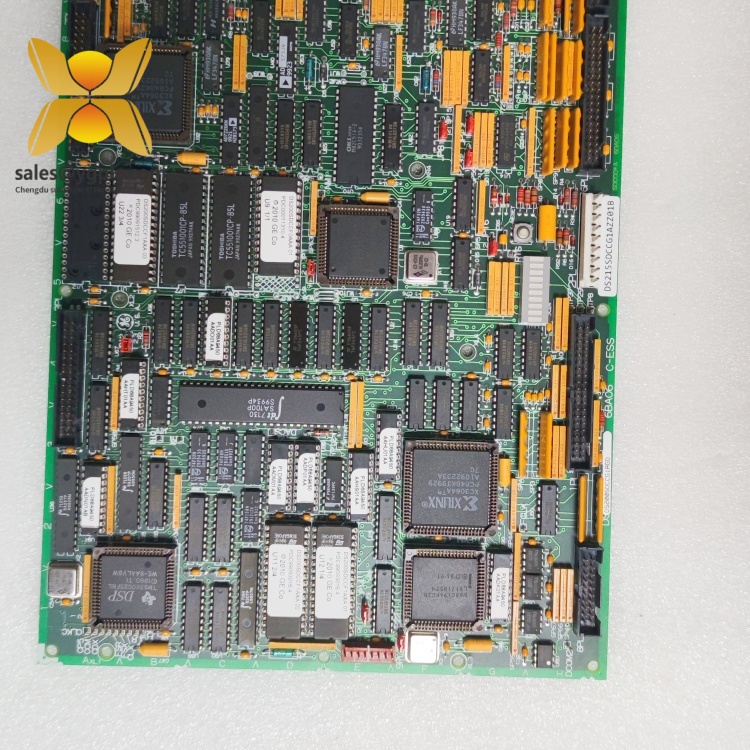

GE DS200SDCCG4AFD Drive Control Board Product Description

Product Overview

The GE DS200SDCCG4AFD is a high-performance drive control board designed for the GE Mark V turbine control system series, a cornerstone of industrial automation in power generation and process industries. As a critical component within the Mark V platform, the GE DS200SDCCG4AFD serves as the primary controller for managing drive operations in gas, steam, and wind turbines, ensuring precise speed regulation, torque control, and system stability. This board integrates three microprocessors—DCP (Drive Control Processor), MCP (Motor Control Processor), and CMP (Co-Motion Processor)—to handle complex real-time tasks, including motor control algorithms, signal processing, and communication with other system modules214.

Engineered with GE’s patented Speedtronic technology, the GE DS200SDCCG4AFD delivers robust reliability and adaptability across demanding environments. Its dual-ported RAM architecture enables seamless data sharing between microprocessors, enhancing operational efficiency and reducing latency. The board supports configurable hardware via jumpers and wire connectors, allowing customization for specific turbine applications, while its EPROM and EEPROM memory slots facilitate easy firmware updates and parameter adjustments214. With a focus on scalability, the GE DS200SDCCG4AFD is ideal for retrofitting legacy systems or integrating into new installations, providing long-term value through compatibility with GE’s broader automation ecosystem.

In industrial settings, the GE DS200SDCCG4AFD plays a pivotal role in optimizing turbine performance, minimizing downtime, and ensuring compliance with safety standards. Its design prioritizes ease of maintenance, with diagnostic LEDs and test points for quick fault identification, and supports software configuration tools like ST2000 and GE Control System Toolbox for streamlined setup214. By leveraging this board, operators can achieve higher energy efficiency, extended equipment lifespan, and improved overall plant productivity.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Type | Drive Control Board |

| Series | Mark V |

| Physical Dimensions | 10.5 x 7.5 inches (266.7 x 190.5 mm) |

| Weight | 1.2 kg |

| Country of Origin | United States |

| Interface Type | Serial (RS-232), Parallel |

| Communication Protocol | Proprietary GE Mark V protocol |

| Power Supply | 24 V DC ±10% |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| PCB Coating | Normal coating for environmental protection |

Main Features and Advantages

The GE DS200SDCCG4AFD stands out for its advanced architecture and versatile functionality. Its three microprocessors work in parallel to execute drive control, motor management, and complex motion algorithms, ensuring real-time responsiveness even in high-load scenarios214. The dual-ported RAM allows simultaneous data access by multiple processors, eliminating bottlenecks and enhancing system throughput. This design also supports hot-swappable components, enabling maintenance without system shutdowns, a critical feature for industries where downtime is costly.

Another key strength is its configurability. The board’s hardware jumpers and software tools allow users to tailor settings for specific turbine types, such as TC2000 drives, by adjusting parameters like speed regulation, torque limits, and fault thresholds14. The inclusion of EPROM and EEPROM memory slots simplifies firmware updates and configuration changes, reducing reliance on specialized technicians. Additionally, the board’s diagnostic LEDs and test points enable rapid troubleshooting, minimizing repair time and maximizing uptime.

Reliability is paramount in industrial applications, and the GE DS200SDCCG4AFD delivers with its rugged construction and environmental resilience. The board’s normal PCB coating protects against dust, moisture, and chemical contaminants, while its wide operating temperature range ensures consistent performance in extreme conditions214. Backed by GE’s decades of expertise in turbine control systems, this product offers a proven track record of durability and compatibility with legacy and modern infrastructure.

Application Fields

The GE DS200SDCCG4AFD is widely deployed in power generation, oil and gas, and industrial manufacturing sectors. In gas and steam turbine systems, it serves as the core controller for drive assemblies, managing startup sequences, load balancing, and emergency shutdowns to prevent equipment damage214. For wind turbines, the board ensures optimal power output by regulating blade pitch and generator speed in response to varying wind conditions. Its compatibility with GE’s Mark V platform also makes it suitable for retrofitting older systems to meet modern efficiency and safety standards.

In petrochemical plants, the GE DS200SDCCG4AFD controls high-voltage motors and compressors, ensuring stable operation during critical processes like refining and pipeline pumping. Its real-time data processing capabilities enable predictive maintenance by monitoring motor health parameters, such as vibration and temperature, to identify potential failures before they occur. The board’s adaptability extends to water treatment facilities, where it manages pumps and drives to maintain consistent flow rates and energy efficiency.

Across these industries, the GE DS200SDCCG4AFD addresses challenges like aging infrastructure, regulatory compliance, and operational efficiency. By integrating with GE’s automation tools, it supports plant-wide optimization, reducing energy consumption and maintenance costs while enhancing overall system reliability.

Related Products

- GE DS200SDCCG4AHD: A predecessor model with similar functionality but fewer memory slots and limited firmware options.

- GE DS200SDCCG4AGD: Features advanced diagnostic capabilities and expanded communication interfaces for modern turbine systems.

- GE DS200SLCCG3ACC: A companion module for signal conditioning and I/O expansion in Mark V systems.

- GE IC670CPU350: A central processing unit (CPU) for Mark V systems, complementing the DS200SDCCG4AFD in complex control architectures.

- GE IC660BBD024: A power supply module ensuring stable voltage delivery to the DS200SDCCG4AFD and other Mark V components.

- GE DS200SDCCG5A: A newer iteration with enhanced processing power and support for next-generation turbine technologies.

- GE IC697MDL250: A PLC module for auxiliary control tasks, integrating seamlessly with the DS200SDCCG4AFD in hybrid automation setups.

- GE IC698CPE040: A communication processor for connecting Mark V systems to higher-level networks, enabling remote monitoring and control.

- GE IC697PWR711: A redundant power supply module for mission-critical applications requiring uninterrupted operation.

- GE DS200SDCIG1: A power supply board for Mark V systems, providing backup power to the DS200SDCCG4AFD during outages.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200SDCCG4AFD, ensure the system is powered off and all safety protocols are followed. Verify compatibility with the existing Mark V platform and confirm that the board’s firmware matches the system requirements. Use anti-static gloves and grounding straps to prevent electrostatic discharge (ESD) damage to sensitive components. Transfer EPROM chips from the old board to the new one, ensuring proper alignment and secure seating. Check jumper settings against the system’s technical documentation to avoid configuration errors214.

Before installing the GE DS200SDCCG4AFD, ensure the system is powered off and all safety protocols are followed. Verify compatibility with the existing Mark V platform and confirm that the board’s firmware matches the system requirements. Use anti-static gloves and grounding straps to prevent electrostatic discharge (ESD) damage to sensitive components. Transfer EPROM chips from the old board to the new one, ensuring proper alignment and secure seating. Check jumper settings against the system’s technical documentation to avoid configuration errors214.

Maintenance Suggestions:

Regular maintenance is key to prolonging the GE DS200SDCCG4AFD’s lifespan. Clean the board quarterly using compressed air to remove dust and debris, and inspect connectors for corrosion or loose connections. Monitor the board’s diagnostic LEDs for fault codes and perform firmware updates as recommended by GE. Replace aging capacitors and other components during routine overhauls to prevent unexpected failures. For critical applications, consider implementing redundant systems to minimize downtime during maintenance.

Regular maintenance is key to prolonging the GE DS200SDCCG4AFD’s lifespan. Clean the board quarterly using compressed air to remove dust and debris, and inspect connectors for corrosion or loose connections. Monitor the board’s diagnostic LEDs for fault codes and perform firmware updates as recommended by GE. Replace aging capacitors and other components during routine overhauls to prevent unexpected failures. For critical applications, consider implementing redundant systems to minimize downtime during maintenance.

Product Guarantee

Our company provides a one-year quality warranty for the GE DS200SDCCG4AFD, covering hardware malfunctions unrelated to misuse or improper installation. During the warranty period, we offer free replacement for defective units and provide technical support to resolve operational issues. For discontinued models or urgent requirements, our global supply chain network ensures rapid procurement of scarce spare parts, supported by a team of experts with deep knowledge of GE’s industrial control systems. We are committed to delivering reliable solutions that keep your operations running smoothly, backed by 17 years of experience in the industrial automation sector.

For inquiries, contact us via WhatsApp at +86 18859254943 or email sales@ygdcs.com.

GE DS200TBQAG1A Servo drive

GE DS200TBQBG1ABB Servo motor,

GE DS200TBQBGIACB Industrial keyboard

GE DS200TBQCG1ABB encoder

GE DS200TBQGG1A regulator

GE DS200TCCAG1B I/O board

GE DS200TCCAG2A Counting plate

GE DS200TCCAG2AHB Optical fiber interface board

GE DS200TCCAG2B Acquisition card

GE DS200TCCAGIACA Gas turbine card

GE DS200TCCAGIAHB FIM card

中文版

中文版